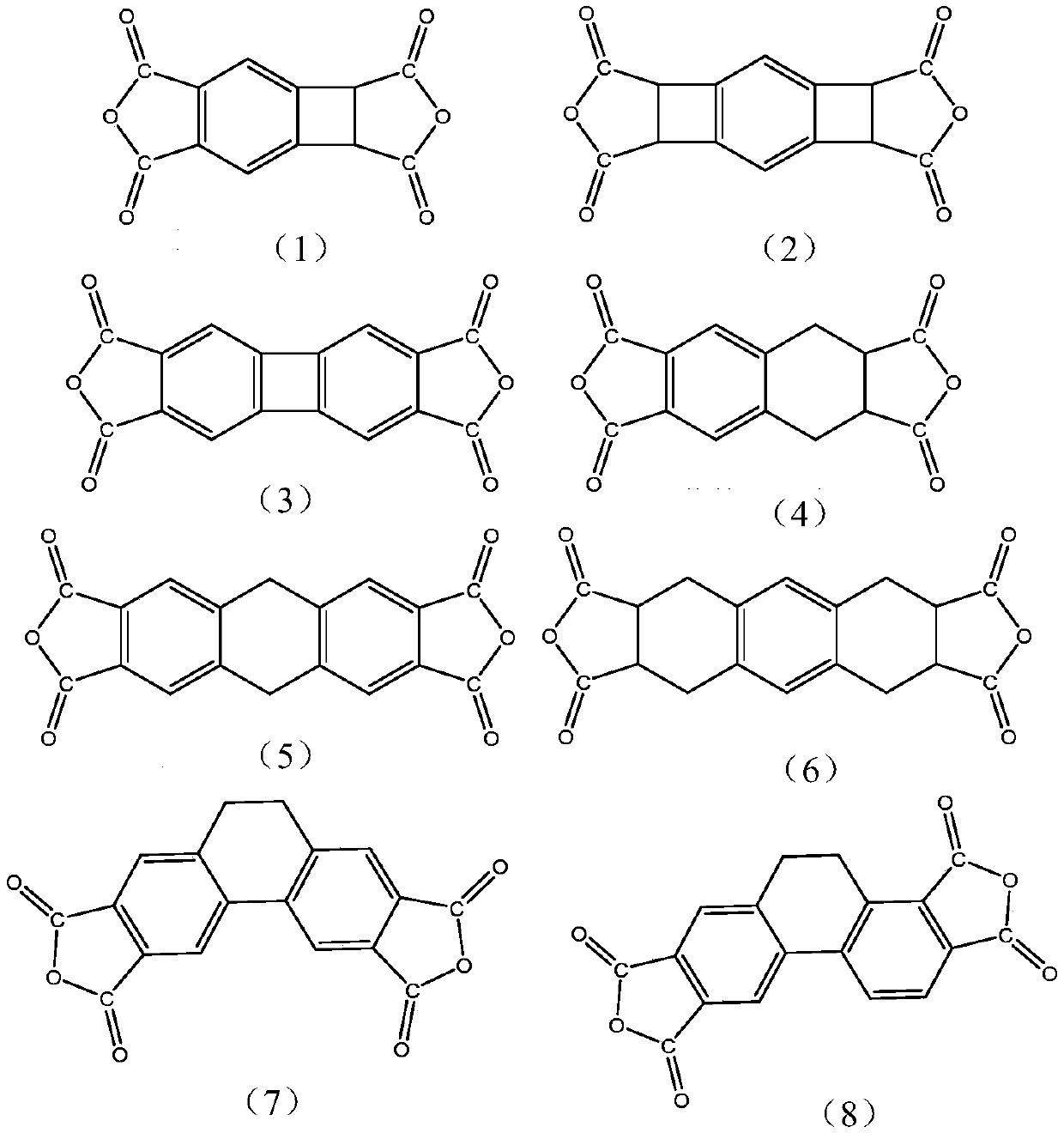

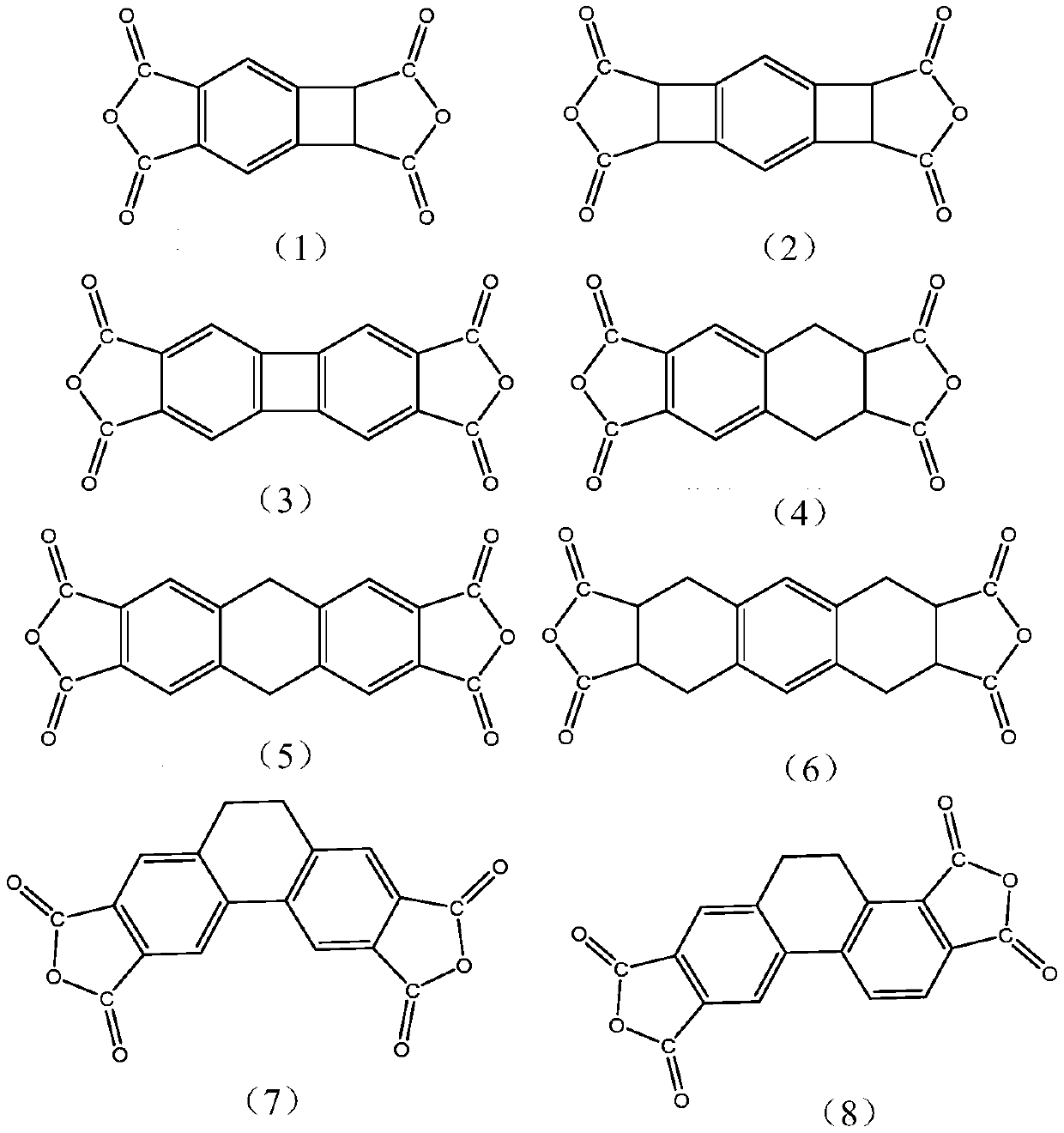

Benzodiacyclic dianhydride and low-dielectric-constant polyimide precursor film

A polyimide precursor, polyimide film technology, applied in the direction of organic chemistry, can solve the problems of mechanical properties and glass transition temperature reduction, difficult to meet 5G high-frequency high-speed communication, affecting performance, etc. Achieve the effects of low thermal expansion coefficient, low dielectric loss, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The polyamic acid solution is prepared according to a known method. 1mol of p-phenylenediamine is fully dissolved in N,N dimethylacetamide, and then 0.95mol of dianhydride a is quickly added to the solution, and under the protection of an inert gas React at 25° C. for 1 h, then add 0.5 wt % (accounting for the total mass) of nanoporous silica (50 nm) with surface amination, and stir rapidly for 2 h. The mass fraction of the total solid content of the final diamine, dianhydride and silicon dioxide is 25wt%. The preparation process of the polyimide film is as follows: a) film coating, the polyamic acid precursor solution is coated on the copper foil substrate by spin coating. b) Imidization, dry the coated substrate at 60°C for 12 hours; then program the temperature rise, and treat it at 150°C, 200°C, and 250°C for 60 minutes; finally raise the temperature to 350°C for 10 minutes, and the imidization reaction It needs to be carried out under nitrogen atmosphere. c) Stre...

Embodiment 2

[0035] The polyamic acid solution was prepared according to a known method, 1mol of 2,2'-bis(trifluoromethyl)benzidine was fully dissolved in N,N dimethylacetamide, and then 1mol of dianhydride a was quickly added to solution, and reacted at 30° C. for 0.5 h under the protection of an inert gas, and then added 0.2 wt % (accounting for the total mass) of nanoporous silicon dioxide (25 nm) with surface fluorination, and stirred rapidly for 4 h. The mass fraction of the total solid content of the final diamine, dianhydride and silicon dioxide is 20wt%. The preparation process of the polyimide film is as follows: a) film coating, the polyamic acid precursor solution is coated on the copper foil substrate by spin coating. b) Imidization, dry the coated substrate at 50°C for 12 hours; then program the temperature rise, and treat it at 150°C, 200°C, and 250°C for 60 minutes; finally raise the temperature to 350°C for 15 minutes, and the imidization reaction It needs to be carried ou...

Embodiment 3

[0037]The polyamic acid solution is prepared according to a known method, 1mol of 3,4-diaminodiphenyl ether is fully dissolved in N,N dimethylacetamide, and then 0.99mol of dianhydride b is quickly added to the solution, And react at 20°C for 1h under the protection of inert gas. The mass fraction of the total solid content of the final diamine, dianhydride and silicon dioxide is 25wt%. The preparation process of the polyimide film is as follows: a) film coating, the polyamic acid precursor solution is coated on the copper foil substrate by spin coating. b) Imidization, dry the coated substrate at 60°C for 10 hours; then program the temperature rise, and treat it at 150°C, 200°C, and 250°C for 75 minutes; finally raise the temperature to 350°C for 20 minutes, and the imidization reaction It needs to be carried out under nitrogen atmosphere. c) Stress relief, control the cooling rate to 5°C / min until room temperature. Finally, the polyimide film was peeled off from the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com