Industrial method for realizing direct ECH (epichlorohydrin) continuous production by phase transfer catalyst

The technology of a phase transfer catalyst and an industrial method, which is applied in the industrial field of direct production of ECH and continuous production, can solve the problems of difficulty in large-scale industrial production, increase excess power consumption, difficult reaction process, etc., so as to increase reaction safety and save energy. Consume and react thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

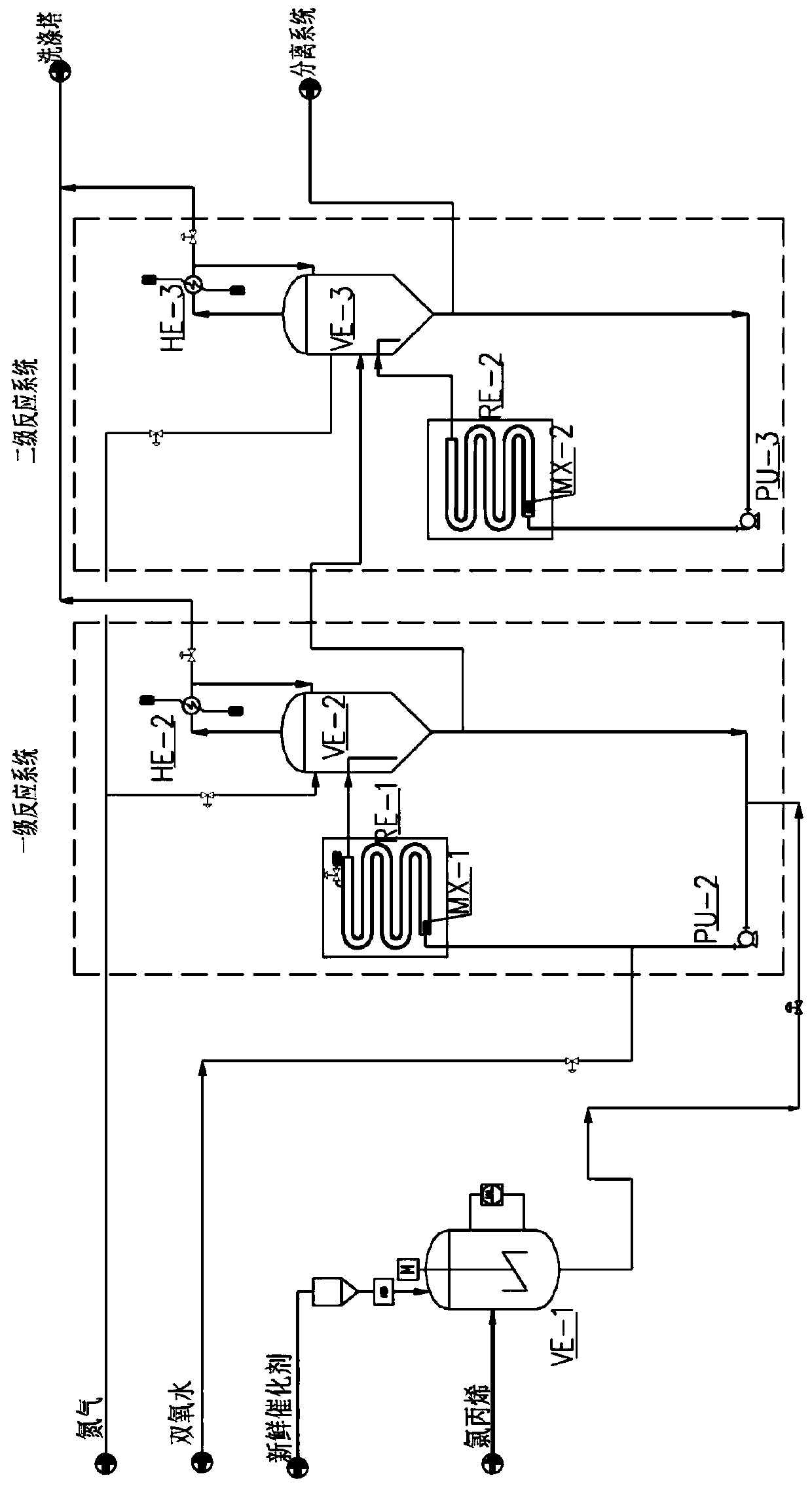

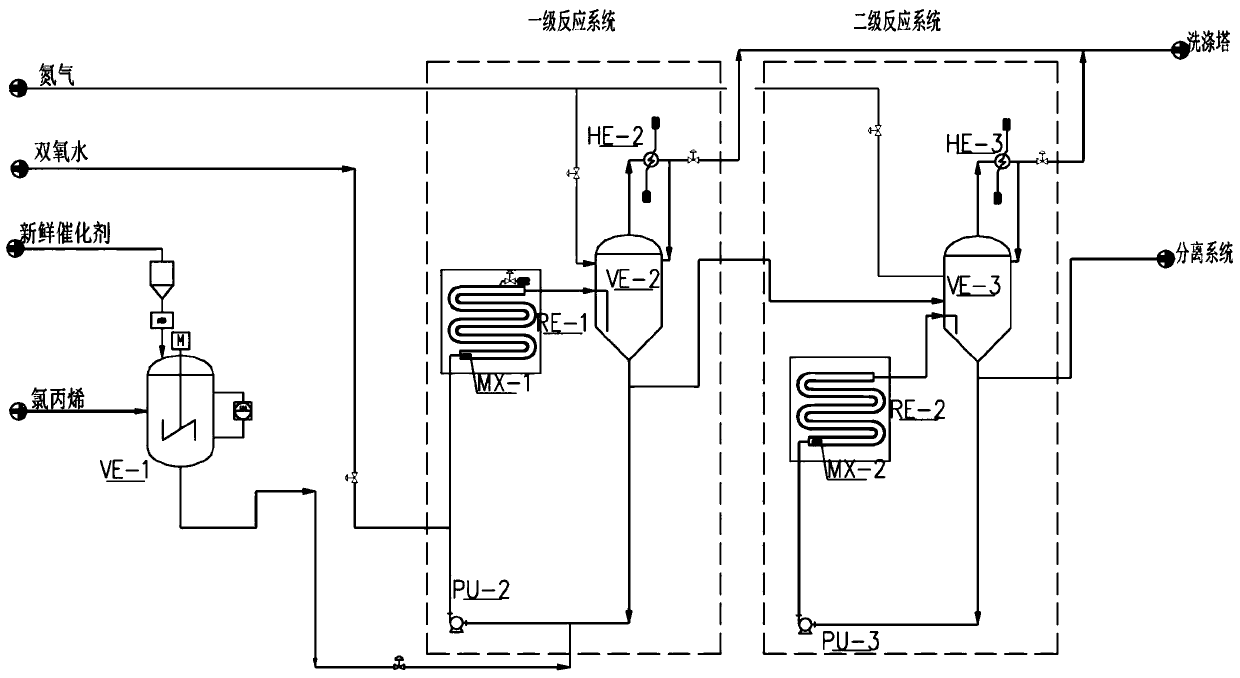

[0020] Such as figure 1 As shown, an industrial method for direct production of ECH using a phase transfer catalyst includes the following steps: (1) Propylene chloride is mixed with the catalyst in the batching tank VE-1 and then enters the first-stage reaction system through the pipeline, and passes through the first-stage reaction system. The reflux pump PU-2 and the hydrogen peroxide added at the inlet of the first-stage tubular reactor RE-1 are mixed in the first-stage mixer MX-1 at the front of the first-stage tubular reactor RE-1 and then reacted in the first-stage tubular reactor. (2) The reacted materials in the first-stage tubular reactor RE-1 enter the first-stage buffer tank VE-2, and the gaseous phase enters the first-stage buffer tank VE-2 together with the nitrogen introduced in the first-stage buffer tank VE-2. VE-2 tank top condenser HE-2 condenses in the first-level buffer tank, the condensed liquid phase is returned to the first-level buffer tank VE-2, and the...

Embodiment 2

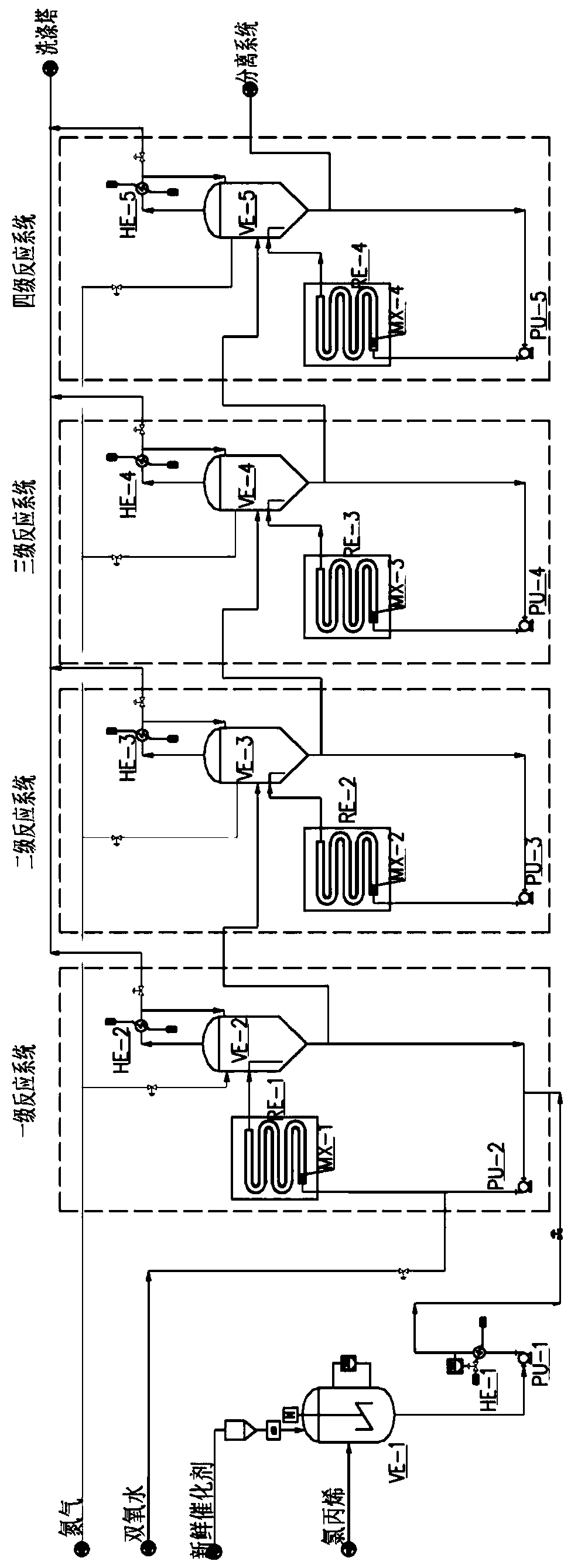

[0023] Such as figure 2 As shown, on the basis of Example 1, an industrial method for direct production of ECH continuous production using a phase transfer catalyst is added in step (1): After the chloropropylene and the catalyst are mixed in the batching tank VE-1, the pump PU-1 enters the preheater HE-1 under pressure for preheating, and then enters the first-stage reaction system after preheating. The preheating temperature is 35-55°C. Steps (3) and (4) correspond to: Step (3) Blow nitrogen into the secondary buffer tank VE-3, and the gas phase in the secondary buffer tank VE-3 enters the top of the secondary buffer tank VE-3 for condensation HE-3 is condensed, and the condensed liquid phase is refluxed to the secondary buffer tank VE-3, and the gas phase enters the scrubber; part of the liquid phase in the secondary buffer tank VE-3 is refluxed to the second stage by the secondary reflux pump PU-3 In the tubular reactor RE-2, the reacted materials re-enter the secondary bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reynolds number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com