Stable superhydrophobic metal surface with three-dimensional three-stage micro-nano structure and preparation method thereof

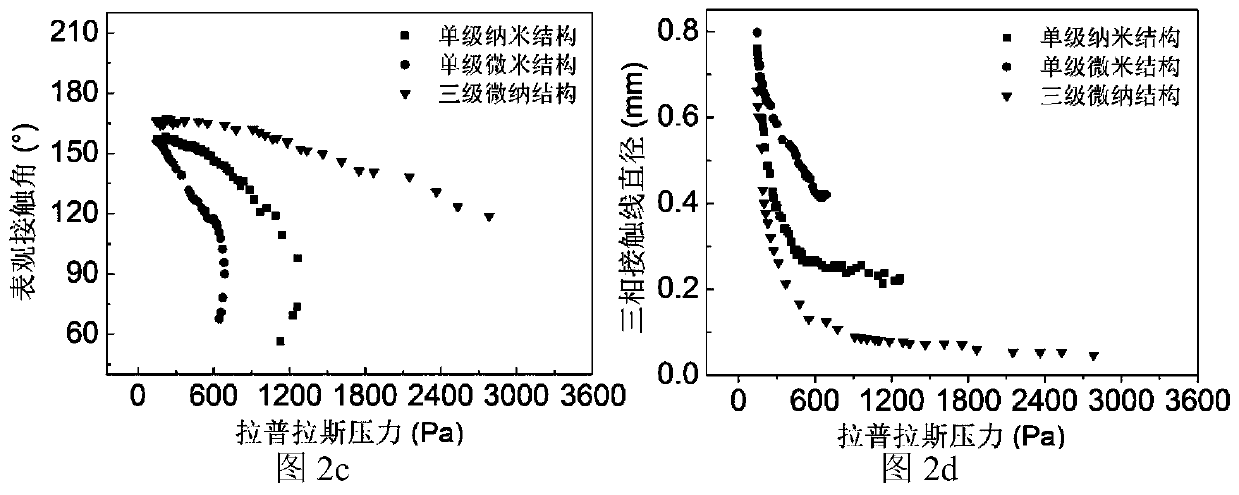

A technology of micro-nano structure and metal surface, applied in metal material coating process, nanotechnology for materials and surface science, nanotechnology, etc. The problems of low-level structure and Cassie state stability of superhydrophobic surface are achieved, and the effect of good structural stability and mechanical durability, increasing complexity and roughness can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Concrete preparation method of the present invention comprises the steps:

[0031] 1) Pretreatment of the metal substrate: make the surface smooth and smooth, remove the oxide layer, and perform ultrasonic cleaning in absolute ethanol and acetone solutions in turn;

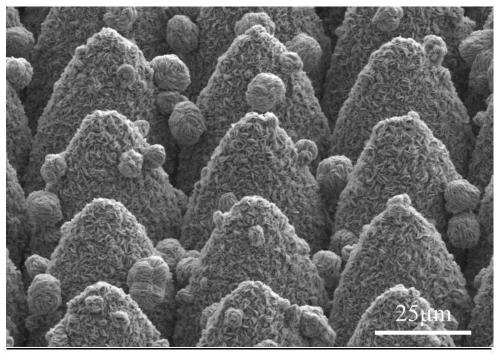

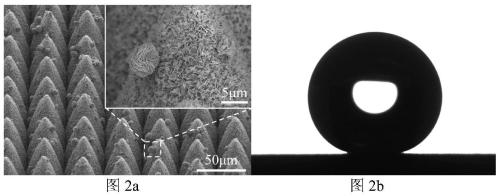

[0032] 2) Preparation of dense micro-cone structure base on the surface of the metal substrate: using a high-power ultrafast pulsed laser to perform selective patterned ablation on the metal surface to process the required three-dimensional dense micro-cone structure base; the high-power Ultrafast pulsed lasers are picosecond or femtosecond lasers;

[0033] 3) Preparation of nanostructures and microspheres or microflowers on the surface of the dense microcone structure base: the above-mentioned sample whose surface is the basis of the three-dimensional dense microcone structure is placed in the prepared oxidation reaction system, and the oxidation reaction system has a concentration of A mixed aqueous solu...

Embodiment 1

[0037] 1) Using metal copper as the base material, first use mechanical cutting to obtain a block copper-based sample with a size of 10mm × 10mm × 6mm, and then use 200#, 400#, 800#, 1000# and 1500# metallographic sandpaper to sand the copper The surface of the base sample was ground and polished step by step, and finally placed in absolute ethanol and acetone for ultrasonic cleaning for 10 to 20 minutes, and then dried in a gentle nitrogen stream after taking it out.

[0038] 2) Perform periodic patterned ablation on the surface of the copper-based sample by using a high-power ultrafast laser. The laser wavelength is 1030nm, the pulse width is 800fs, the pulse repetition frequency is 200kHz, and the laser power is 15W. Processing, the distance between adjacent scanning lines is 60 μm, the scanning speed is 700 mm / s, and the height of the three-dimensional microcone unit is 90 μm, the diameter of the bottom is about 60 μm, and the period is 60 μm. After the ablation is complete...

Embodiment 2

[0043] 1) Using metal copper as the base material, first use mechanical cutting to obtain a block copper-based sample with a size of 10mm×10mm×6mm, and then use 200#, 400#, 800#, 1000# and 1500# metallographic sandpaper to The surface of the copper-based sample was ground and polished in sequence, and finally ultrasonically cleaned in absolute ethanol and acetone for 10 to 20 minutes, and then dried in a gentle nitrogen stream after taking it out.

[0044] 2) Periodic patterned ablation is performed on the surface of the copper-based sample by using a high-power ultrafast laser. The laser wavelength is 532nm, the pulse width is 10ps, the pulse repetition frequency is 600kHz, and the laser power is 20W. Scanning processing, the distance between adjacent scanning lines is 20 μm, the scanning speed is 100 mm / s, and the height of the three-dimensional microcone unit is 20 μm, the bottom diameter is about 30 μm, and the period is 30 μm. After the ablation is completed, the sample is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com