Flexible reflector film of sunlight reflector

A mirror and sunlight technology, applied in the field of sunlight reflection, can solve the problems of complex composite process of multi-layer polymer polyester material film, aging and damage of polymer organic polymer, shortened service life, etc., to achieve stable work and use Long-lasting, easy-to-create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

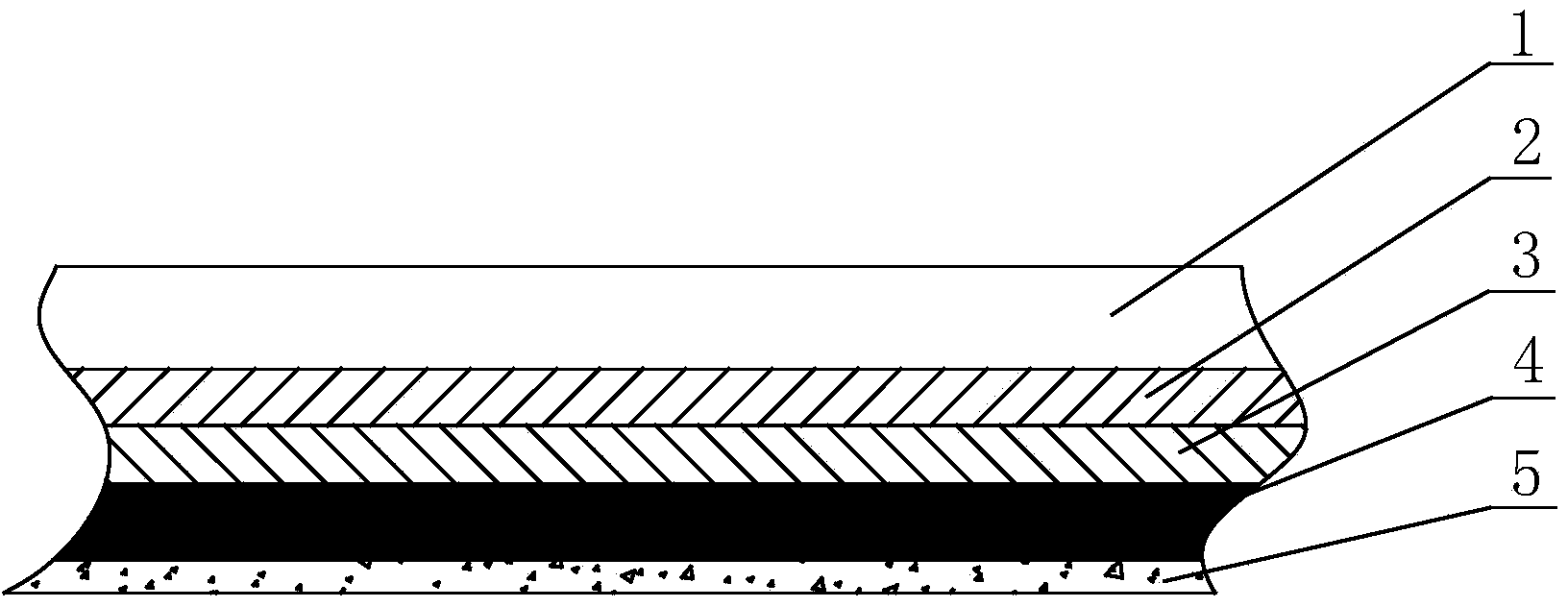

[0032] Such as figure 1 The first solar reflector flexible mirror film shown is the most basic mirror film structure of the present invention, and it has a five-layer film composite structure: viewed along the sunlight incident direction, it is successively one layer of transparent flexible inorganic material carrier film 1 , a layer of reflective film 2 of metal material, a layer of protective film 3 of metal material, a layer of pressure-sensitive adhesive adhesive film 4 and a layer of pressure-sensitive adhesive peeling protection film 5. Among them, the transparent and flexible inorganic material carrier film 1 is an ultra-thin flexible glass film with a commercial name of "Willow Glass". The thickness of the ultra-thin flexible glass film is δ=100 μm. The performance of breaking, also has the characteristics that the energy is not easily absorbed when sunlight passes through, and it is not sensitive to ultraviolet light. The metal reflective film 2 is made of silver met...

Embodiment 2

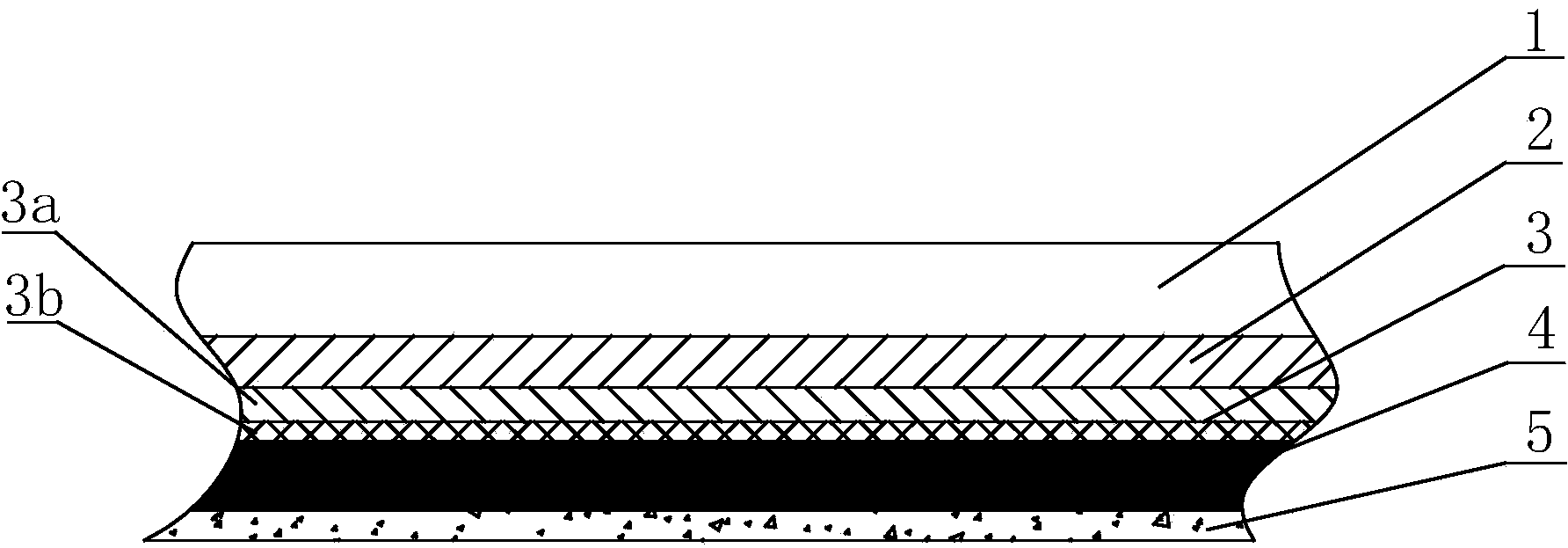

[0035] Such as figure 2 The film composite structure of the second solar reflector flexible mirror film shown is basically the same as that of Embodiment 1. The difference is that the metal protective film 3 is an aluminum metal film 3a and its surface naturally accompanied by an aluminum oxide film 3b, or an aluminum metal film 3a and its surface a dense aluminum oxide film 3b that is forcibly oxidized. In this way, replacing the copper metal film with aluminum metal film can not only effectively reduce the material cost, but also the dense Al attached on the aluminum metal surface 2 o 3 The film has excellent resistance to moisture and acid and alkali corrosion, so as to maintain the stability of the mirror film and prolong the service life of the mirror film.

Embodiment 3

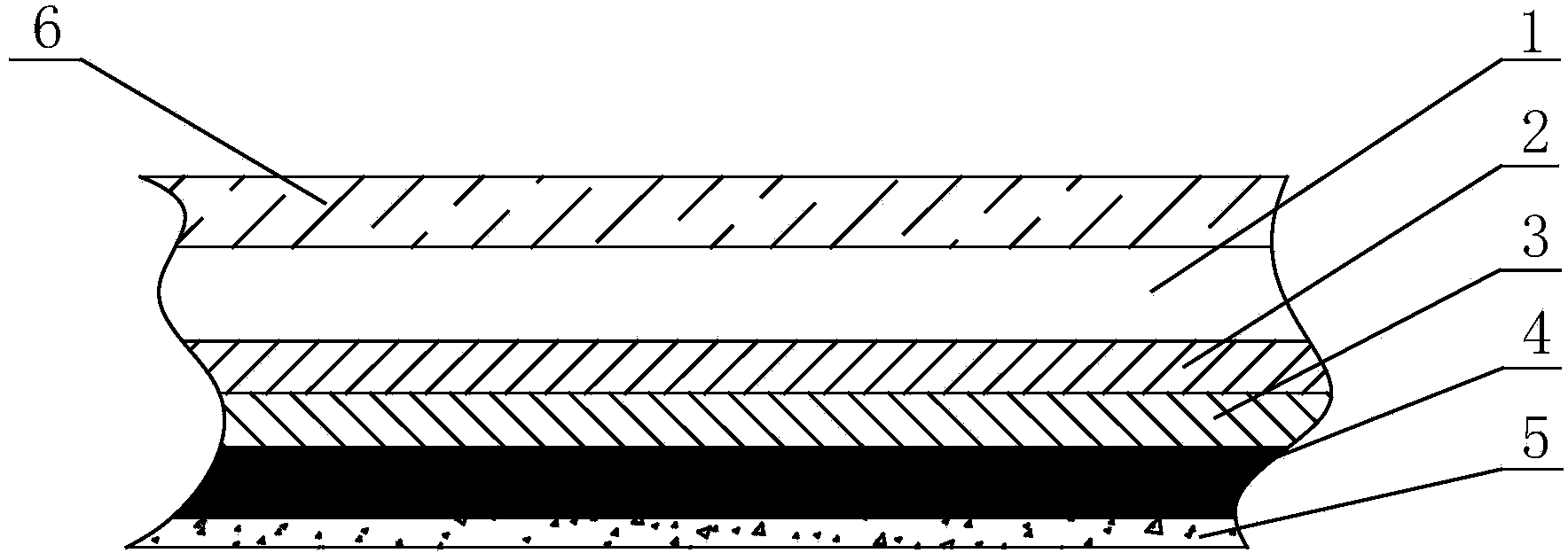

[0037] Such as image 3 The film composite structure of the third flexible mirror film for sunlight reflector shown is basically the same as that of Embodiment 1. The difference is that a layer of nano-hydrophobic coating 6 is coated on the transparent flexible inorganic material carrier film 1 (ie ultra-thin flexible glass film). Described nano-hydrophobic coating 6 can select water-soluble TiO for use 2 Nano-coating, also can choose water-soluble Al 2 o 3 Nano coatings. This kind of coating can quickly form a layer of nano-hydrophobic film when it is directly coated, which is firmly attached to the surface of the ultra-thin flexible glass film, and has various functions such as waterproof, dustproof, antibacterial, heat-resistant, acid and alkali resistant, and UV-resistant. , It also makes the outer surface of the reflector placed outdoors have a self-cleaning function, easy to clean (washing or blowing with compressed air), and not easy to bind dust, so as to ensure it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com