High strength and toughness heat resistant die casting mg-gd-y alloy and preparation method thereof

A hot die casting and mg-gd technology is applied in the field of high strength, toughness and heat resistance die casting Mg-Gd-Y alloy and its pressure casting preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

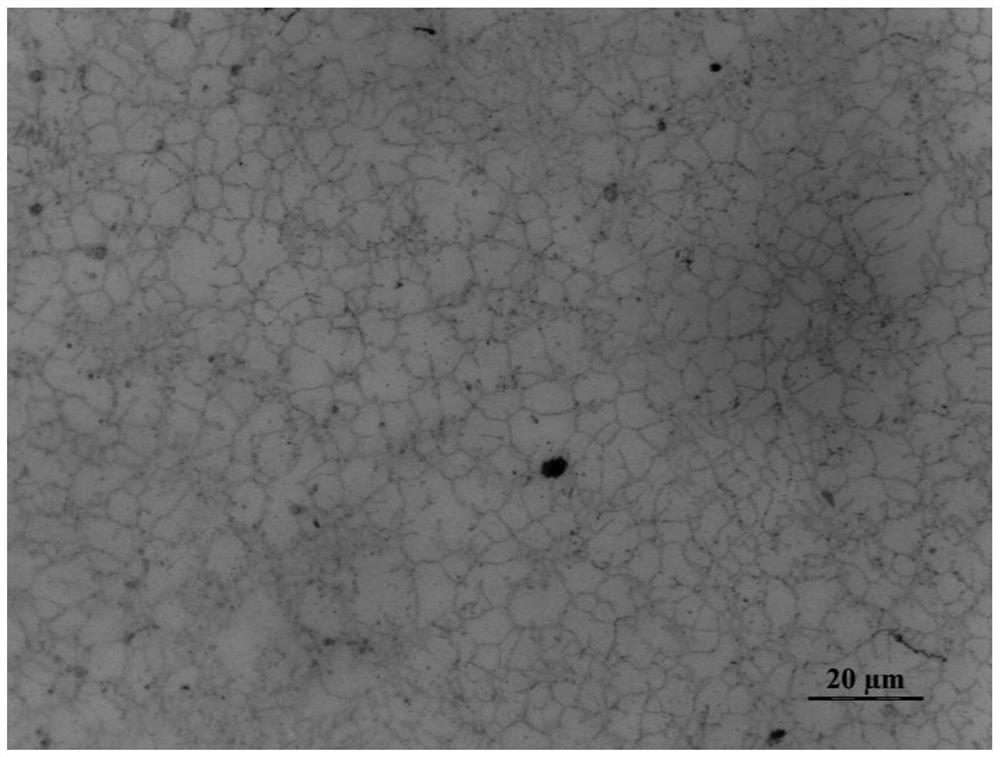

Image

Examples

Embodiment 1

[0038] The percentage by weight of a high-strength and tough heat-resistant die-casting Mg-Gd-Y alloy involved in this embodiment is: according to the theoretical ratio, 0.6% Gd, 2.4% Y, 1.2% Zn, 1.2% Al, 0.3% Mn, 0.01% Ti, 0.01% B, the balance is Mg and other unavoidable impurities.

[0039] Its preparation method is: (1) according to the above-mentioned Mg-Gd-Y alloy composition and stoichiometric ratio, calculate the consumption of required raw materials; mix industrial pure magnesium ingot, industrial pure zinc, industrial pure aluminum ingot and MgGd25, MgY30 and MgMn10 intermediate Remove the oxide layer from the alloy, dry and preheat to 200°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy; (2) melt the industrial pure magnesium ingot accounting for 25% of the crucible height at 680°C into After the molten pool, the protective gas argon is introduced, and the remaining magnesium ingots are added; (3) af...

Embodiment 2

[0042] The percentage by weight of a high-strength and tough heat-resistant die-casting Mg-Gd-Y alloy involved in this embodiment is: according to the theoretical ratio, 2.0% Gd, 5.0% Y, 4.2% Zn, 0.8% Al, 0.1% Mn, 0.08% Ti, the balance is Mg and other unavoidable impurities.

[0043] Its preparation method is (1) according to above-mentioned Mg-Gd-Y alloy composition and stoichiometric ratio, calculate the consumption of required raw material; Industrial pure magnesium ingot, industrial pure zinc, industrial pure aluminum ingot and MgGd30, MgY30 and MgMn10 master alloy Remove the oxide layer and dry and preheat to 180°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy; (2) Melt the industrial pure magnesium ingot accounting for 20% of the crucible height at 675°C After the pool, pass through the protective gas containing 0.2% volume fraction of SF 6 and CO 2 (3) After the magnesium ingots are completely melted...

Embodiment 3

[0046] The percentage by weight of a high-strength and tough heat-resistant die-casting Mg-Gd-Y alloy involved in this embodiment is: according to the theoretical ratio, 3.0% Gd, 3.0% Y, 3.0% Zn, 0.9% Al, 0.2% Mn, 0.05% Ti, 0.03% B, the balance is Mg and other unavoidable impurities.

[0047] Its preparation method is (1) according to above-mentioned Mg-Gd-Y alloy composition and stoichiometric ratio, calculate the consumption of required raw material; Industrial pure magnesium ingot, industrial pure zinc, industrial pure aluminum ingot and MgGd30, MgY25 and MgMn10 master alloy Remove the oxide layer and dry and preheat to 200°C; calculate the amount of raw materials required according to the composition and stoichiometric ratio of the alloy; (2) Melt the industrial pure magnesium ingot accounting for 20% of the crucible height at 680°C After the pool, the protective gas argon is introduced, and the remaining magnesium ingots are added; (3) After the magnesium ingots are compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com