Wax-containing 3D printing light-cured cast resin and preparation method thereof

A 3D printing and casting resin technology, applied in the field of 3D printing, can solve the problems of low strength, high ash content, high thermal expansion coefficient, etc., and achieve the effect of low viscosity, low ash content and superior mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

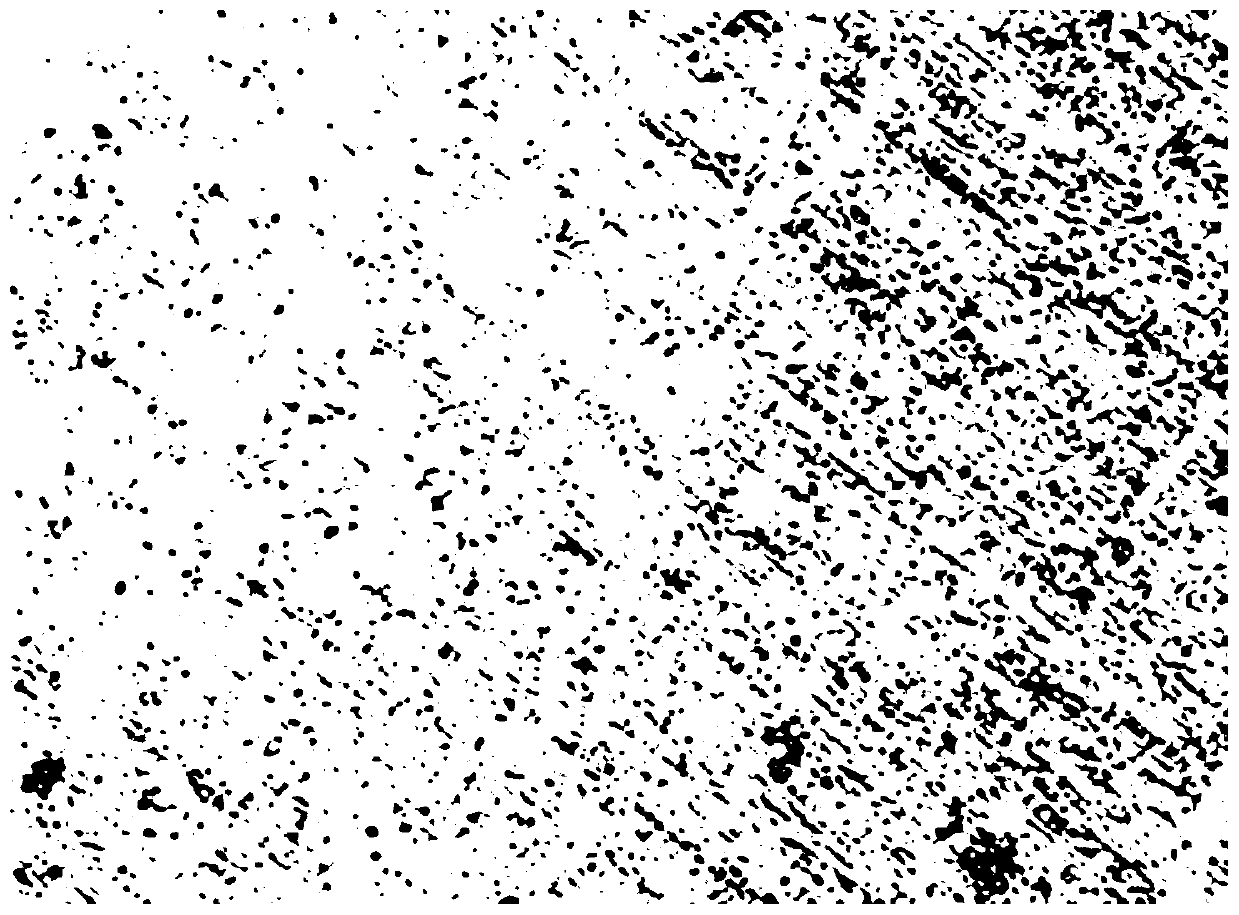

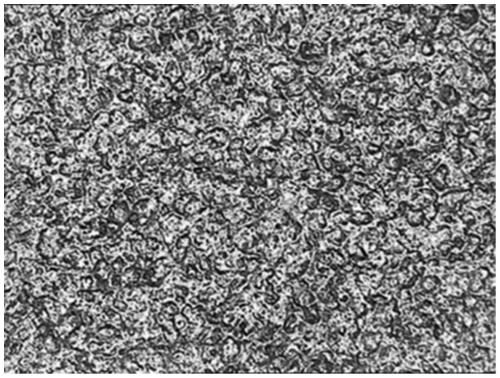

Image

Examples

Embodiment 1

[0039] In parts by weight, add Twax-05064 parts and BYK-P1041 parts into a container containing 40 parts of acrylic monomers, disperse at high speed for 20-30 minutes, and then add 50 parts of linear alkane polyurethane acrylic resin, 2 parts of benzoin diethyl ether, 1 part of phthalocyanine blue, 1 part of BYK-0561, 1 part of BYK-0711, disperse at high speed for 10-15 minutes for each material added, after the last material is added, continue to disperse at high speed for 30 minutes until the liquid is uniform, and then The liquid mixture is poured into a sand mill for grinding to obtain a wax-containing 3D printing light-curing casting resin.

Embodiment 2

[0047] In parts by weight, add 1 part of PEW-05111 part and 1 part of BYK-P104S into a container containing 15 parts of cyclotrimethylolpropane methylal acrylate monomer, disperse at high speed for 20-30 minutes, and then pour them into the container according to the proportion Add 80 parts of polyester acrylate, 2 parts of 1-hydroxycyclohexyl phenyl ketone, 0.2 parts of permanent orange, 0.4 parts of BYK-501A, and 0.4 parts of BYK-1410. After one material is added, the whole continues to be dispersed at high speed for 30 minutes until the liquid is uniform, and then the liquid mixture is poured into a sand mill for grinding to obtain a wax-containing 3D printing light-curing casting resin.

[0048] Similar to Example 1, the viscosity of the wax-containing 3D printing light-curing casting resin prepared in this example is 320cps@25°C, the Shore hardness is 60D (according to ASTM DIN EN ISO 868 standard), and the ash content is 0.048% (according to GB / T14235.3-1993 standard), t...

Embodiment 3

[0050] In parts by weight, add Clanrant CERIDUST 36101 parts and BYK-P1050.01 parts into a container containing 60 parts of cycloacrylamide monomer, disperse at high speed for 20-30 minutes, and then add polyester acrylate 30 parts in proportion to the container 1 part, 8 parts of benzophenone, 0.79 part of phthalocyanine red, 0.1 part of BYK-501A, 0.1 part of BYK-0720. Each material added is dispersed at high speed for 10-15 minutes. After the last material is added, the whole continues to disperse at high speed for 30 minutes to The liquid is uniform, and then the liquid mixture is poured into a sand mill for grinding to obtain a wax-containing 3D printing photocurable casting resin.

[0051] Similar to Example 1, the viscosity of the wax-containing 3D printing light-curing casting resin prepared in this example is 382cps@25°C, the Shore hardness is 52D (according to ASTM DIN EN ISO 868 standard), and the ash content is 0.040% (according to GB / T14235.3-1993 standard), the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com