Method for preparing antifriction anti-fretting strengthening layer on surface of titanium alloy

A technology of titanium alloy and strengthening layer, which is applied in the field of preparing anti-friction and anti-fretting strengthening layer on the surface of titanium alloy, which can solve the problems affecting the structure and performance of titanium alloy matrix, the wear resistance of titanium alloy surface is not very ideal, and the processing temperature is high , to improve the anti-fretting performance, solve the effect of thin permeable layer, weak binding force of membrane base and large thickness of permeable layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

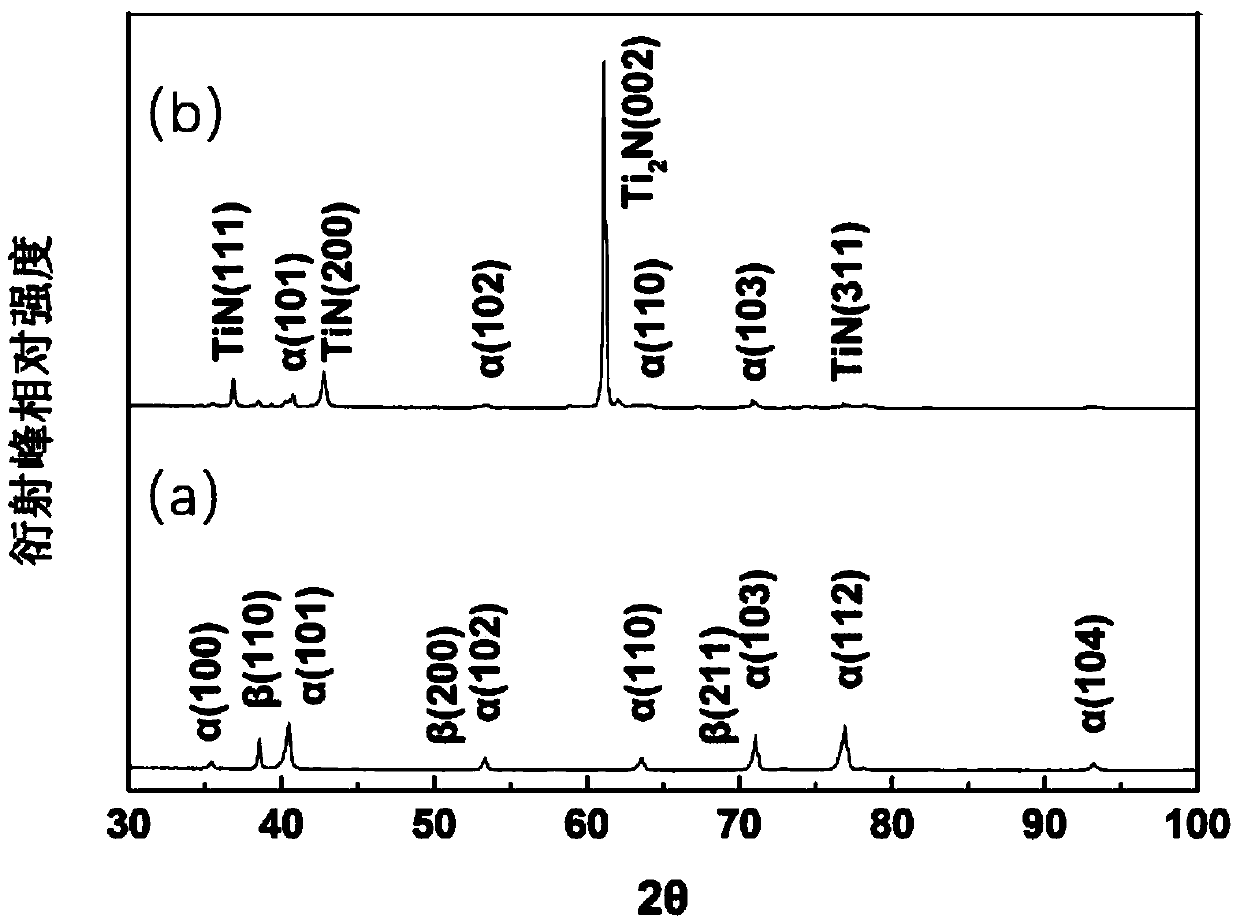

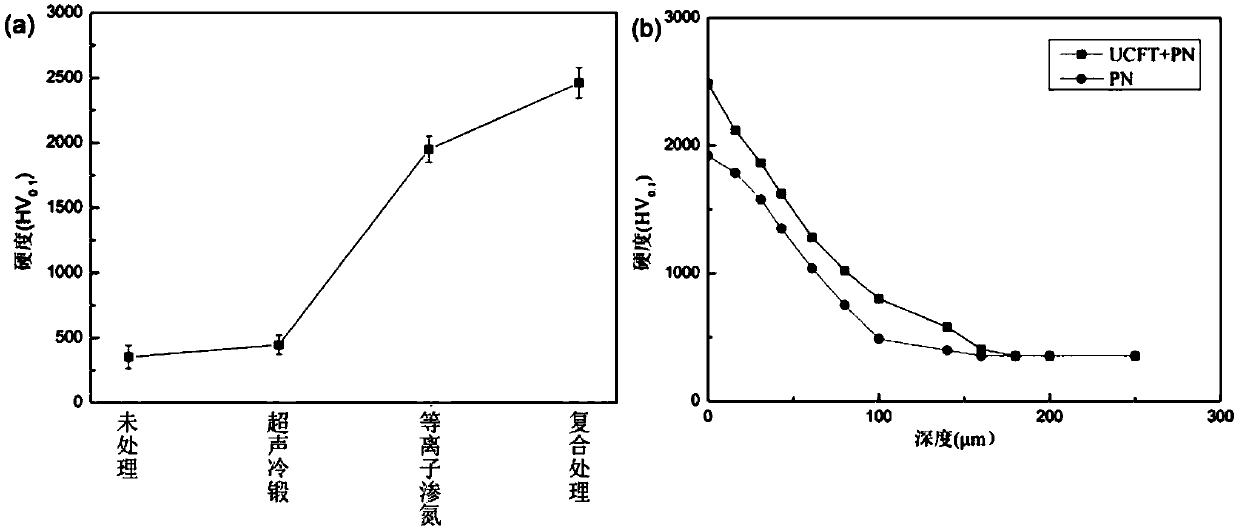

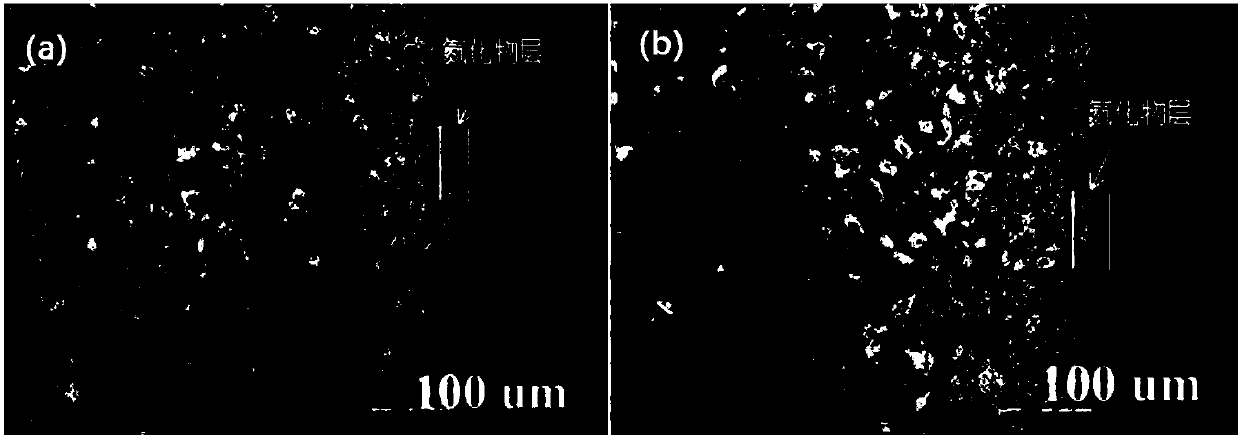

[0037] The present invention will be further described below in conjunction with accompanying drawing:

[0038] Sample Preparation:

[0039] (1) Grind the titanium alloy with SiC sandpaper 600#, 800#, 1000#, 1200#, 1500#, 2000# in turn, polish the polishing cloth until the surface roughness is below 1 μm, and then use acetone or alcohol to perform ultrasonic cleaning for 15 -20min, get the sample;

[0040] (2) Put the sample on the chuck of the machine tool in the ultrasonic cold forging equipment, clamp it with screws, turn on the power, observe the display screen, set the processing parameters as: working current 0.78A, frequency 20KHz, amplitude 10μm, so that Ultrasonic vibration;

[0041] (3) Add the mixed solution of cutting fluid and water into the water tank of the ultrasonic cold forging equipment, run the CNC machine tool in the ultrasonic cold forging equipment, the spindle speed of the CNC machine tool is 150r / min, the feed rate is 0.03mm / r, and the static pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com