Preparation method of anti-aging uvioresistant shading net

An anti-ultraviolet and sunshade net technology, which is applied in rayon manufacturing, fiber chemical characteristics, textiles, etc., can solve the problems of easy aging and insufficient anti-ultraviolet ability of sunshade nets, so as to achieve difficult peeling, improve anti-oxidation ability, and strengthen cross-linking structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

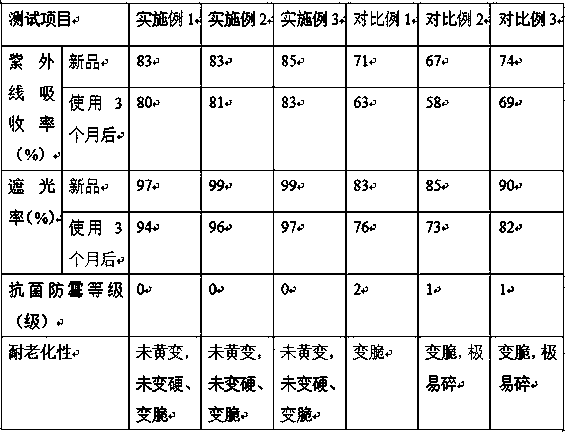

Examples

Embodiment 1

[0031] Preparation of the reaction product:

[0032]Put 500g of cotton in an oven, dry at 60°C for 2 hours to obtain a dry product, put the dry product and distilled water into the reactor at a mass ratio of 1:5, seal the reactor, and fill the reactor with argon until the pressure inside the reactor rises to 1.2MPa, and at the same time raise the temperature inside the reactor to 120°C, and react at constant temperature and pressure for 60 minutes to obtain a reaction product.

[0033] Preparation of fermentation products:

[0034] Add the hydrochloric acid of 16% concentration of reaction product mass and be 0.5mol / L in above-mentioned reactor, mix and stir 80min with the rotating speed of 400r / min with stirring device, after stirring, add dropwise the sodium hydroxide solution that mass fraction is 12% to adjust pH value to neutral to prepare the mixture, by weight, 8 parts of the mixture, 1 part of citric acid, 3 parts of pulverized cotton stalks and 15 parts of water are ...

Embodiment 2

[0044] Preparation of the reaction product:

[0045] Put 600g of cotton in an oven, dry at 65°C for 2 hours to obtain a dry product, put the dry product and distilled water into the reactor at a mass ratio of 1:5, seal the reactor, and fill the reactor with argon until the pressure in the reactor rises to 1.4MPa, and at the same time raise the temperature in the reactor to 130°C, and react at constant temperature and pressure for 70 minutes to obtain a reaction product.

[0046] Preparation of fermentation products:

[0047] Add the hydrochloric acid with the concentration of 18% of the reaction product mass to 0.5mol / L in the above reaction kettle, mix and stir with a stirring device at a speed of 450r / min for 90min, after stirring, add dropwise a mass fraction of 14% sodium hydroxide solution to adjust the pH value to neutral to prepare the mixture, by weight, 9 parts of the mixture, 1 part of citric acid, 4 parts of pulverized cotton stalks and 16 parts of water are droppe...

Embodiment 3

[0057] Preparation of the reaction product:

[0058] Put 700g of cotton in an oven and dry for 3 hours at a temperature of 70°C to obtain a dry product. Put the dry product and distilled water into the reactor at a mass ratio of 1:5, seal the reactor, and fill the reactor with argon Gas until the pressure inside the reactor rises to 1.6MPa, and at the same time raise the temperature inside the reactor to 140°C, and react at constant temperature and pressure for 80 minutes to obtain the reaction product.

[0059] Preparation of fermentation products:

[0060] Add 20% of the mass of the reaction product to the reaction kettle and add 0.5mol / L hydrochloric acid with a concentration of 0.5mol / L, mix and stir for 100min with a stirring device at a speed of 500r / min, and after stirring, add dropwise a 16% sodium hydroxide solution to adjust the pH value to neutral to prepare the mixture, by weight, 10 parts of the mixture, 2 parts of citric acid, 5 parts of pulverized cotton stalks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com