Preparation method and applications of rice bran polysaccharide iron

A technology of rice bran polysaccharide and ferric chloride hexahydrate, which is applied in the field of polysaccharides, can solve the problems of large cell toxicity and achieve the effect of low cytotoxicity, low cytotoxicity and high bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

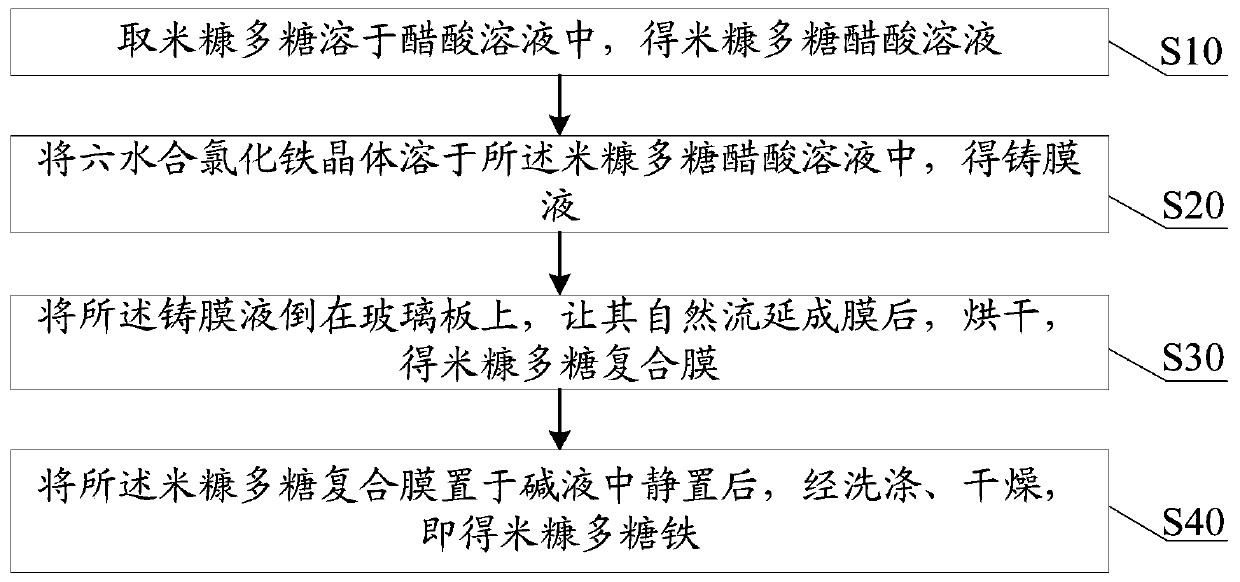

Method used

Image

Examples

Embodiment 1

[0054] Take 10mL of 1% acetic acid solution, and configure it into rice bran polysaccharide acetic acid solution, and the mass concentration of rice bran polysaccharide in the solution is 0.6%. Then add 3g FeCl 3 ·6H 2 O crystals were ultrasonically treated for 10-15 minutes to dissolve them completely to obtain a casting solution.

[0055] Pour the film-casting liquid onto a clean and dry glass plate, let it cast naturally to form a film, and then dry it in an oven at 50°C to obtain rice bran polysaccharide-FeCl 3 Composite film.

[0056] The dried rice bran polysaccharide-FeCl 3 The composite membrane was soaked in 0.06mol / L NaOH solution and left to stand for 7 days, then taken out, washed with ethanol and acetone, and dried to obtain iron rice bran polysaccharide.

Embodiment 2

[0058] Take 10mL of 2% acetic acid solution, and configure it into rice bran polysaccharide acetic acid solution, and the mass concentration of rice bran polysaccharide in the solution is 0.8%. Then add 4g FeCl 3 ·6H 2 O crystals were ultrasonically treated for 10-15 minutes to dissolve them completely to obtain a casting solution.

[0059] Pour the film-casting liquid onto a clean and dry glass plate, let it cast naturally to form a film, and then dry it in an oven at 45°C to obtain rice bran polysaccharide-FeCl 3 Composite film.

[0060] The dried rice bran polysaccharide-FeCl 3 The composite film was soaked in 0.1mol / L NaOH solution and left to stand for 7 days, then taken out, washed with ethanol and acetone, and dried to obtain iron rice bran polysaccharide.

Embodiment 3

[0062] Take 10mL of 1% acetic acid solution, and configure it into rice bran polysaccharide acetic acid solution, and the mass concentration of rice bran polysaccharide in the solution is 0.5%. Then add 2g FeCl 3 ·6H 2 O crystals were ultrasonically treated for 10-15 minutes to dissolve them completely to obtain a casting solution.

[0063] Pour the film-casting liquid onto a clean and dry glass plate, let it cast naturally to form a film, and then dry it in an oven at 40°C to obtain rice bran polysaccharide-FeCl 3 Composite film.

[0064] The dried rice bran polysaccharide-FeCl 3 The composite film was soaked in 0.08mol / L NaOH solution and left to stand for 6 days, then taken out, washed with ethanol and acetone, and dried to obtain iron rice bran polysaccharide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com