A kind of biological material and its preparation method and its application as bone defect repair material

A technology of biomaterials and bioceramic materials, applied in the field of biomaterials and their preparation, and bone defect repair materials, can solve the problems of limited printing height, yellowing of materials, and low printing accuracy of biomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

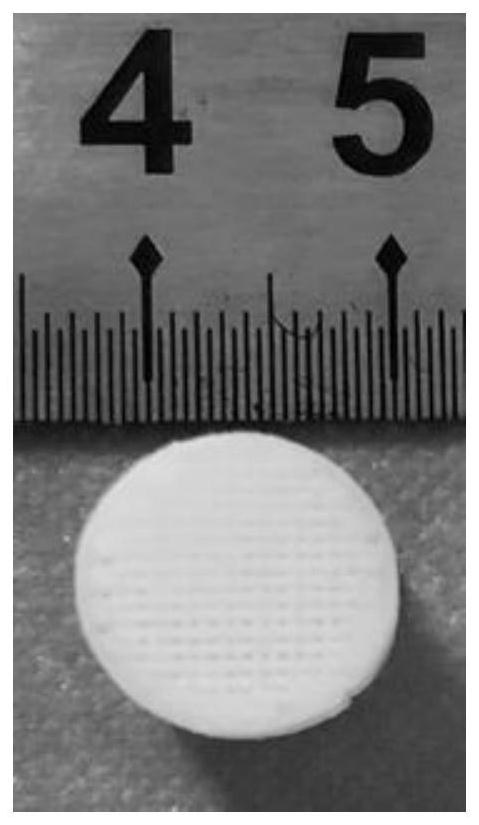

[0032] Example 1: C-CS 0.4g+Gel-MA 2.2g+HAP 5g+photocrosslinking+EDC / NHS crosslinking

[0033] The preferred embodiment of the present invention provides an extrusion type 3D printing biological material for bone defect repair. The biological 3D printing slurry formula includes an organic polymer part, an inorganic bioceramic particle part and a photoinitiating additive part.

[0034] The organic polymer part is composed of Gel-MA and C-CS. Take the C-CS 0.4g and dissolve it in 11mLH under magnetic stirring 2 After adding 2.2 g of the Gel-MA in O, it was completely dissolved under stirring in a water bath at 50°C.

[0035] The photoinitiator additive partly consists of photoinitiator 819 and photoinitiator 184. Take the 0.15g photoinitiator 819 and 0.25g photoinitiator 184, and dissolve them in 0.4 mL of acetone to completely dissolve, and the solution becomes slightly yellow. The prepared photo-initiating additive is partially added to the organic polymer solution, and magneticall...

Embodiment 2

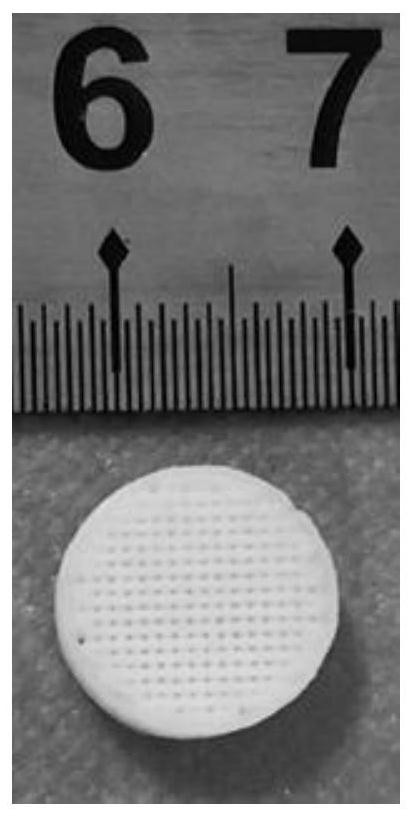

[0039] Example 2: C-CS 0.8g+Gel-MA 3.2g+photocrosslinking

[0040] In the biological 3D printing slurry component for bone repair of the present invention, the organic polymer part can be printed independently without relying on inorganic particles.

[0041] Take 0.8 g of the C-CS and dissolve it in 11 mL of water with magnetic stirring, then add 3.2 g of the Gel-MA, and dissolve completely in a water bath at 50°C. The photoinitiator additive partly consists of photoinitiator 819. Take 0.15 g of the photoinitiator 819 and dissolve it in 0.4 mL of acetone until it is completely dissolved.

[0042] The prepared photo-initiating additive is partially added to the organic polymer solution, and magnetically stirred until it is completely miscible to form a uniform solution.

[0043] Transfer the slurry to the extrusion-type bioprinter barrel, match the needle with 0.16mm aperture, set the air pressure to about 0.15MPa, the line speed 6mm / s, the line spacing set 0.3mm, and the 330-365nm ul...

Embodiment 3

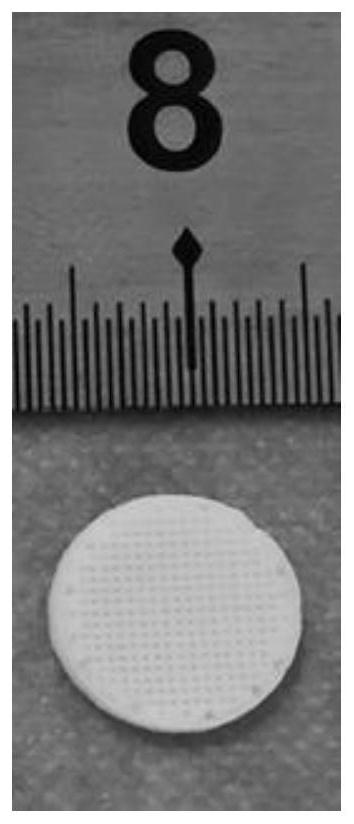

[0044] Example 3: C-CS 0.4g+Gel-MA 2.2g+HAP 3g+glutaraldehyde crosslinking

[0045] Take 0.4g of the C-CS and dissolve it in 11mL H 2 After adding 2.2 g of the Gel-MA in O, it was completely dissolved in a water bath at 50°C.

[0046] The part of the inorganic bioceramic particles (hydroxyapatite) was sieved twice with a standard sieve with an aperture of 0.15 mm, and 3 g of the sieved particles were taken. The inorganic bioceramic particles were added to the above-mentioned homogeneous solution in five times. After each addition, Put it into a planetary centrifugal mixer and mix for about 15 minutes. After the last 3g is added, mix for 1 hour to obtain a uniform and stable slurry.

[0047] Transfer the slurry to the extruded bio-printer barrel, match the needle with 0.41mm aperture, set the air pressure to about 0.4MPa, the line speed 8mm / s, the line spacing setting 1.1mm, the platform temperature 4℃, the barrel temperature 30℃ To print. After printing, put the stent into 1.25% gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com