Preparation method of ultrathin lithium metal negative electrode

A metal negative electrode and ultra-thin lithium technology, applied in the direction of electrode manufacturing, battery electrodes, structural parts, etc., can solve the problems of inability to achieve tight pressing, reduced discharge capacity, small tab area, etc., to reduce heat generation power and improve Power characteristics, the effect of improving the voltage platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

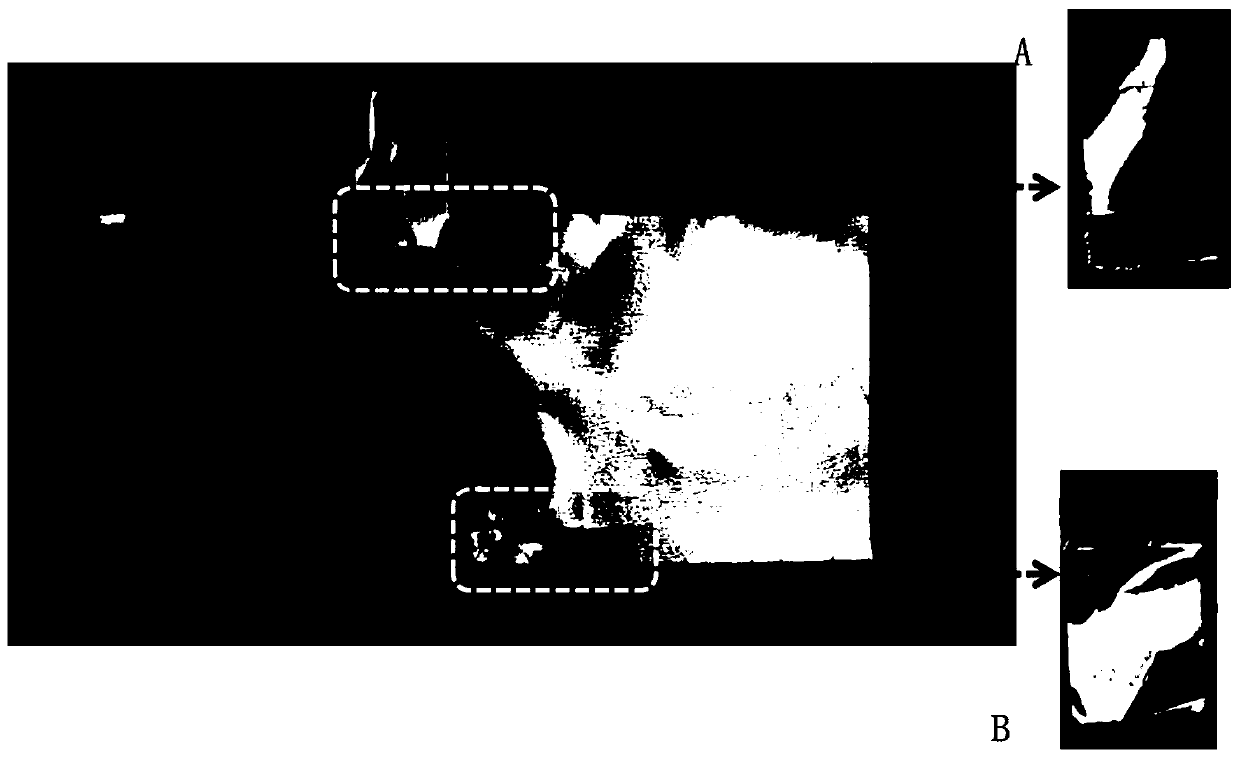

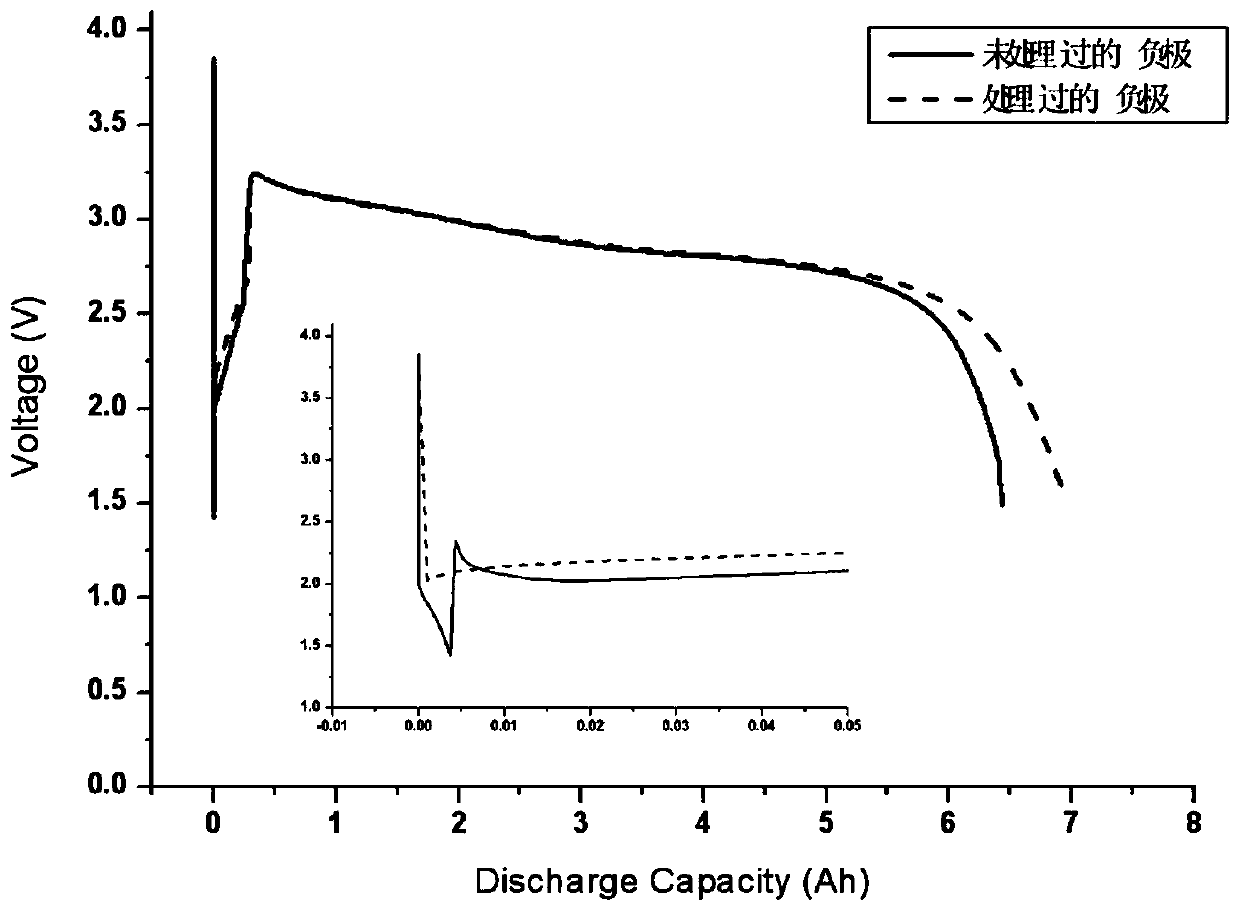

[0023] see Figure 1 to Figure 3 Disclosed is a method for preparing an ultra-thin lithium metal negative electrode. The negative electrode sheet includes a negative electrode tab 1 and an ultra-thin lithium foil 2, so that the ultra-thin lithium sheet and the current collector tab can be tightly combined. It includes: a brush for processing ultra-thin lithium sheets, an ultra-thin lithium sheet and current collector tabs. After the ultra-thin lithium sheets are processed by the brush, they are pressed together by pressing equipment so that they can be tightly connected to the current collector tabs. integrate.

[0024] Wherein, the material of the brush for processing the ultra-thin lithium sheet is natural bristle, horse hair, sisal, soft plastic fiber, nylon, polypropylene (PP), polyethylene (PE), PBT and the like. The brush for processing the ultra-thin lithium sheet can evenly remove the surface passivation layer and increase the roughness of the lithium sheet surface. ...

Embodiment 1

[0028] Step 1 Lithium sheet cutting

[0029] Cut the 0.065mm thick lithium ribbon into 135*59mm size.

[0030] Step 2 Tab 1 Cutting

[0031] The copper foil is cut into 15 mm wide and 20 mm long, the thickness of the copper foil is 10 μm, and the surface of the copper foil is smooth.

[0032] Step 3 Lithium sheet processing

[0033] Before the ultra-thin lithium sheet 2 is bonded to the copper foil, use a soft brush made of horse hair to evenly brush the bonding area between the lithium sheet and the tab, remove the passivation layer of the lithium sheet in the tab area, and increase the lithium sheet in this area the roughness;

[0034] Step 4 Negative pole piece pressing

[0035] Bond the collector lugs to the treated lithium sheet area, use plane pressing equipment, and set the equipment pressure to 0.3MPa; wrap the prepared negative electrode sheet with polypropylene film (to prevent the lithium sheet from bonding to the pressure plate) ); put the negative electrode s...

Embodiment 2

[0037] Step 1 Lithium sheet cutting

[0038] Cut the 0.050mm thick lithium ribbon into 100*80mm size.

[0039] Step 2 Tab cutting

[0040] Cut the copper foil into 10 mm wide and 20 mm long, the thickness of the copper foil is 8 μm, and the surface of the copper foil is smooth.

[0041] Step 3 Lithium sheet processing

[0042] Before the ultra-thin lithium sheet is bonded to the copper foil, use a brush made of nylon 610 to evenly brush the bonding area between the lithium sheet and the tab, remove the passivation layer of the lithium sheet in the tab area, and increase the roughness of the lithium sheet in this area Spend;

[0043] Step 4 Negative pole piece pressing

[0044] Bond the collector lugs to the treated lithium sheet area, use plane lamination equipment, and set the equipment pressure to 0.5MPa; wrap the prepared negative electrode sheet with polypropylene film (to prevent the lithium sheet from bonding to the pressure plate) ); place the negative electrode sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com