Preparation method of nozzle nano refractory material

A refractory material and nozzle technology, which is applied in the field of nozzle nano refractory material preparation, can solve the problems of inability to increase the working life of the nozzle, no innovation in the thermal shock resistance principle, and prolonged thermal shock resistance time, etc., and achieves high hardness, tight adhesion, and prolonged Effect of impact resistance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

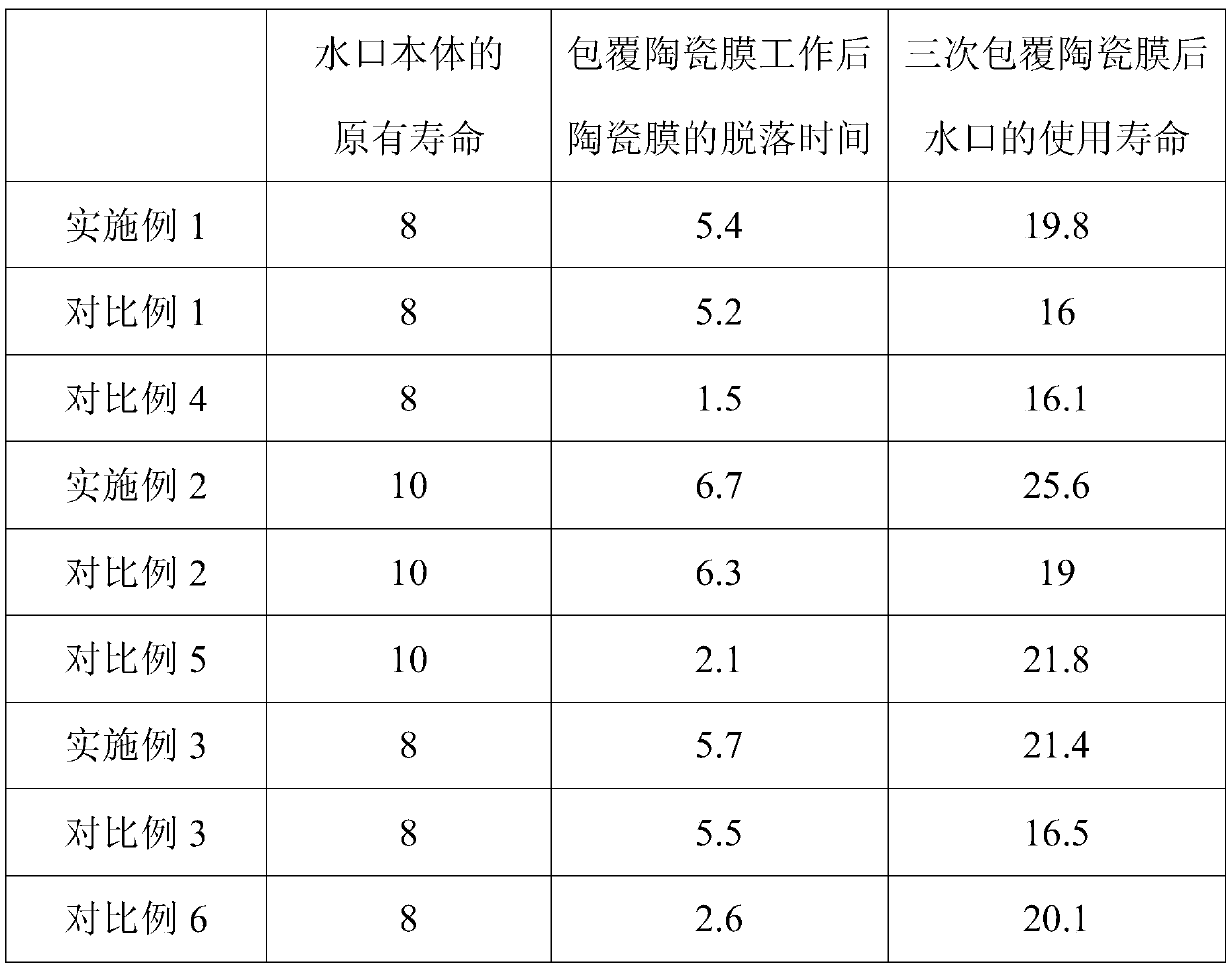

Examples

Embodiment 1

[0040] The method for preparing nano-refractory material in this embodiment may further comprise the steps:

[0041] (1) Prepare the nano-film layer first: mix nano-alumina, nano-silicon micropowder, and nano-silicon carbide with a mass ratio of 1:0.2:0.1; the particle diameters of the three nano-materials are all 500 nanometers.

[0042] (2) add 3% binding agent and 20% water that the weight is the sum of these three kinds of raw materials, mix and coat on the working surface of long nozzle or submerged nozzle, coating thickness is 50 microns, at 180 Drying at ℃ to obtain a long nozzle or submerged nozzle covered with a nano-film layer.

[0043] (3) prepare ceramic film layer then: the weight of each raw material is:

[0044] Al 2 o 3 : 50kg; SiC: 20kg; ZrO 2 : 5kg; SiN 4 : 2kg;

[0045] Calcined kaolin: 5kg; talc: 3kg;

[0046] 6 micron small particle size pore forming agent PMMA: 10kg; 22 micron large particle size pore forming agent PMMA: 15kg;

[0047] Binder meth...

Embodiment 2

[0052] The method for preparing nano-refractory material in this embodiment may further comprise the steps:

[0053] (1) Prepare the nano-film layer first: mix nano-alumina, nano-silicon micropowder, and nano-silicon carbide with a mass ratio of 1:0.3:0.3; the particle sizes of the three nano-materials are 200 nm, 300 nm, and 300 nm, respectively. .

[0054] (2) add 5% binding agent and 30% water that the weight is the sum of these three kinds of raw materials, mix and coat on the working surface of long nozzle or submerged nozzle, coating thickness is 40 microns, at 160 Drying at ℃ to obtain a long nozzle or submerged nozzle covered with a nano-film layer.

[0055] (3) prepare ceramic film layer then: the weight fraction of each raw material is:

[0056] Al 2 o 3 : 50kg; SiC: 25kg; ZrO 2 : 6kg; SiN 4 : 3kg;

[0057] Calcined kaolin: 6kg; talc: 4kg;

[0058] 5 micron small particle size pore forming agent PS: 12kg; 20 micron large particle size pore forming agent PS: 1...

Embodiment 3

[0064] The method for preparing nano-refractory material in this embodiment may further comprise the steps:

[0065] (1) Prepare the nano-film layer first: mix nano-alumina, nano-silicon micropowder, and nano-silicon carbide with a mass ratio of 1:0.2:0.3; the particle diameters of the three nano-materials are all 200 nanometers;

[0066] (2) add 4% binder and 25% water that the weight is the sum of these three raw materials, mix uniformly and apply on the working surface of the long nozzle or submerged nozzle, the coating thickness is 30 microns, at 150 Dry at ℃ to obtain a long nozzle or submerged nozzle covered with a nano-film layer;

[0067] (3) prepare ceramic film layer then: the weight fraction of each raw material is:

[0068] Al 2 o 3 : 40kg; SiC: 30kg; ZrO 2 : 8kg; SiN 4 : 4kg;

[0069] Calcined kaolin: 7kg; talc: 5kg;

[0070] 8 micron small particle size pore former toner: 15kg; 25 micron large particle size pore former toner: 20kg;

[0071] Binder hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com