A method for fixing arsenic by stabilizing arsenic-alkali slag to prepare scorodite

A technology for stabilization treatment and arsenic-alkali slag, which is applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of secondary pollution costs, etc., and achieve stable and safe treatment, simple treatment process, and high uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

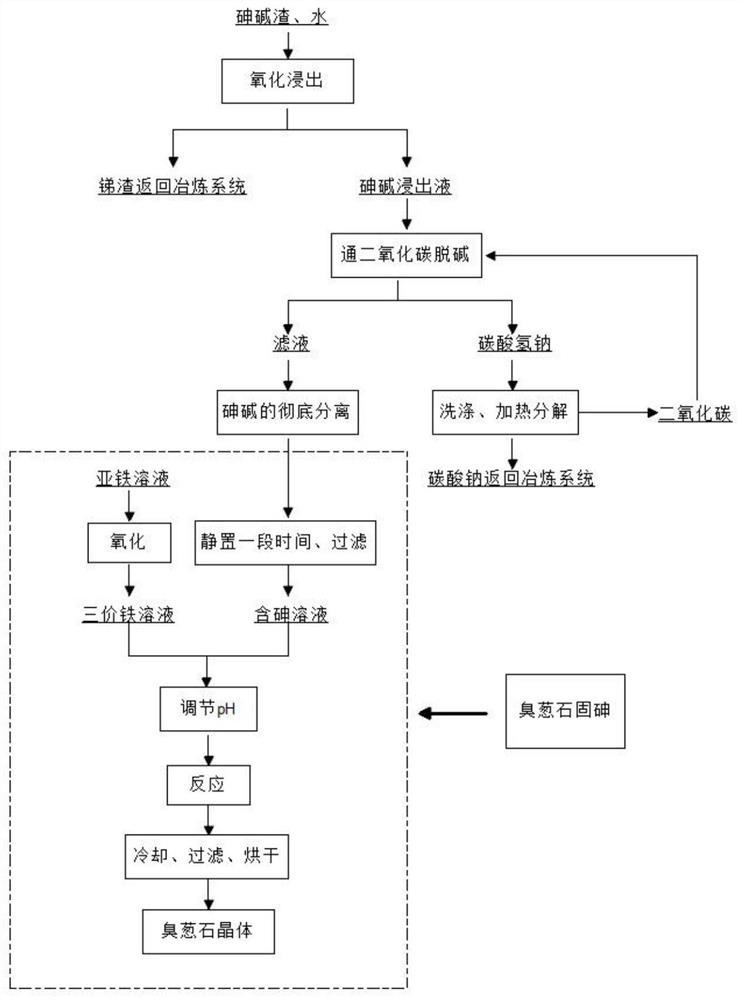

Method used

Image

Examples

Embodiment 1

[0029] Take 900g of arsenic-alkali slag, the liquid-solid ratio L / S is 4:1, the leaching temperature is 85°C and the leaching time is 45min as the leaching conditions, and an excess of 30% H 2 o 2 The solution is oxidized. After the reaction, solid-liquid separation is carried out, and the antimony-containing precipitate is returned to the antimony smelting system; the leachate is concentrated by half, and CO 2 to pH 8.0. Add concentrated sulfuric acid to the leaching solution gained by filtration to remove remaining alkali, leave standstill, filter to obtain the required arsenic-rich solution, analyze the concentration of As in the solution with inductively coupled plasma optical emission spectrometer (ICP-OES) to be 16.5g / L;

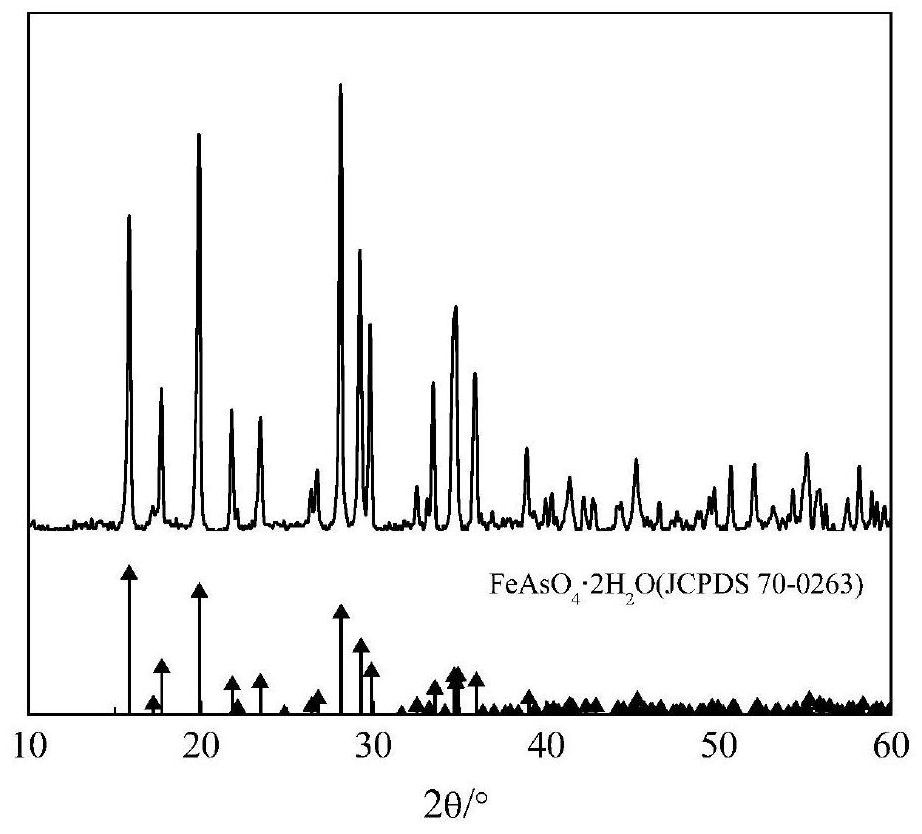

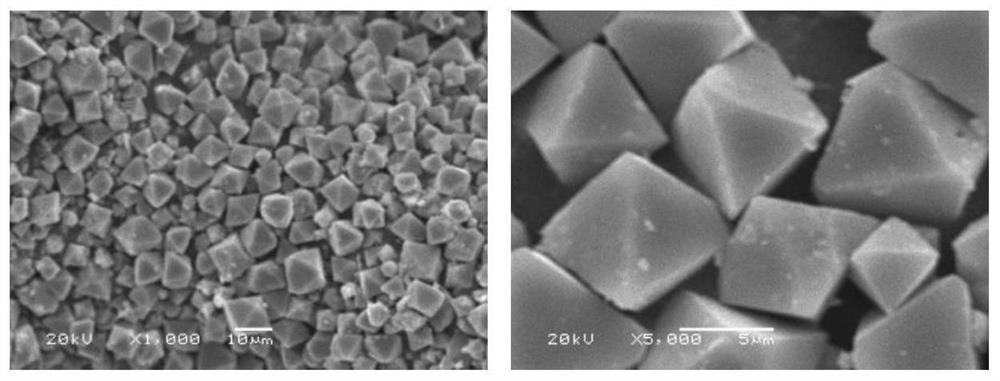

[0030] Measure 30mL of the above-mentioned arsenic-rich solution, and prepare FeSO 4 solution, with an appropriate amount of 30% H 2 o 2 After the solution oxidizes Fe(II), mix the iron-arsenic solution evenly, adjust the pH to 1.5, and heat to ...

Embodiment 2

[0033] Scorodite was prepared according to the method in Example 1, the initial pH value in the reaction system was controlled to be 1.8, and the rest of the reaction conditions remained unchanged, and the resulting precipitate was characterized by XRD as scorodite crystals.

[0034] Leaching toxicity test: refer to "Method 1311: ToxicityCharacteristic Leaching Procedure" promulgated by the US Environmental Protection Agency in 1992 to conduct a leaching toxicity test. The leaching concentration of As in the filtrate is determined to be 0.21mg / L, which has high environmental stability and can be stored safely. .

Embodiment 3

[0036] Scorodite was prepared according to the method of Example 1, the molar ratio of Fe / As in the reaction system was controlled to be 2.0, and the rest of the reaction conditions remained unchanged, and the obtained precipitate was characterized as scorodite crystal by XRD.

[0037] Leaching toxicity test: refer to the "Method 1311: ToxicityCharacteristic Leaching Procedure" promulgated by the US Environmental Protection Agency in 1992 to conduct a leaching toxicity test. The leaching concentration of As in the filtrate was determined to be 0.53mg / L, which has high environmental stability and can be stored safely. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com