Preparation method of high-purity monascus pigment component

A technology of monascus pigment and high purity, which is applied in the field of biochemical products, can solve the problems of small processing capacity and difficult separation and purification of monascus pigment, and achieves the effects of simple operation steps, saving consumption of separation materials and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Red yeast rice has a rice color value of 5100 U / g, contains red pigments (erythematine and monascorubin) 10.1 g / Kg, orange pigments (erythematin and monascorubin) 48.3 g / Kg, and yellow pigments (monasculin and red Triflavin) 41.9 g / Kg. After crushing to a particle size of 0.1mm, using 70% (weight ratio, the same below) ethanol solution extraction (60°C water bath, solid-liquid ratio 1:10), vacuum concentration to 1 / 2 the original volume to precipitate the crude monascus pigment extract , The yield is 10.1%.

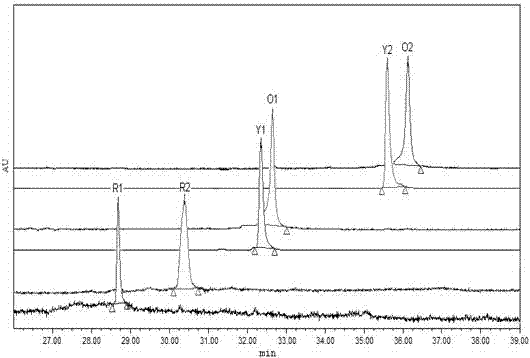

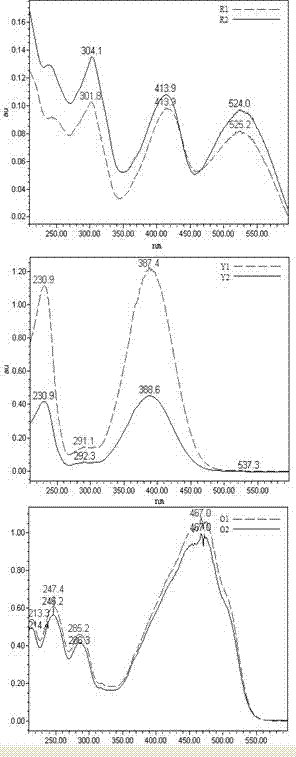

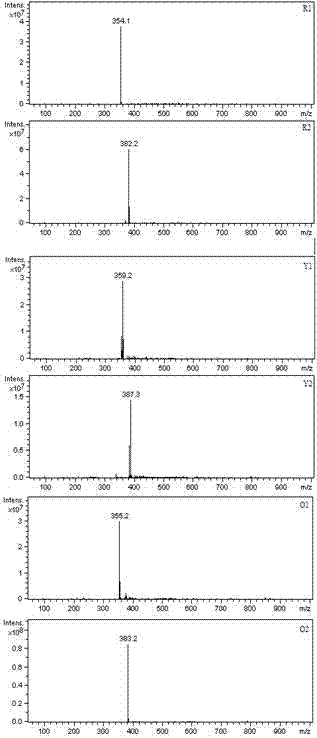

[0023] A high-speed countercurrent chromatography system with a column volume of 300 mL was used for separation. Select n-hexane-methanol-water as the solvent system, according to the ratio of 10:7.5:2.5 (v:v:v:v), dispose the above solvent components in the separatory funnel, shake well and stand for stratification. Take the upper layer as the stationary phase and the lower layer as the mobile phase.

[0024] Weigh 200 mg of crude monascus pigment extract and dissol...

Embodiment 2

[0028] Red yeast rice has a color value of 3000 U / g, crushed to a particle size of 1 mm, extracted with a 70% (weight ratio, the same below) methanol solution (60℃ water bath, solid-liquid ratio 1:15), and then concentrated to the original volume 1 / 3. The crude monascus pigment is separated out, the yield is 6.7%.

[0029] A high-speed countercurrent chromatography system with a column volume of 1000 mL was used for separation. Select petroleum ether-ethyl acetate-ethanol-water as the solvent system, according to the ratio of 2.5:7.5:5:5 (v:v:v:v), dispose the above solvent components in the separatory funnel, shake well and then stand still 置layered. Take the upper layer as the stationary phase and the lower layer as the mobile phase.

[0030] Weigh 800mg of the crude monascus pigment extract and dissolve it with 50mL stationary phase for use. Before injection, fill the entire column volume with the stationary phase, adjust the host speed to 900rpm / min, pump the mobile phase in...

Embodiment 3

[0033] Red yeast rice has a color price of 4000 U / g, crushed to a particle size of 1 mm, and extracted with a 90% acetone aqueous solution (60°C water bath, solid-liquid ratio 1:5), and the extracted extract is vacuum concentrated to 1 / 3 of the original volume to precipitate. The crude extract of monascus pigment component has a yield of 8.5%.

[0034] A high-speed countercurrent chromatography system with a column volume of 1000 mL was used for separation. Choose cyclohexane-chloroform-isopropanol-water as the solvent system, according to the ratio of 5:6:8:2.5 (v:v:v:v), dispose the above solvent components in the separatory funnel, shake well Let stand for layering. Take the upper layer as the stationary phase and the lower layer as the mobile phase.

[0035] Weigh 800mg of the crude monascus pigment extract and dissolve it with 50mL stationary phase for use. Before injection, fill the entire column volume with the stationary phase, adjust the host speed to 900rpm / min, pump t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com