Method for removing calcium and magnesium from bioleaching solution of nickel cobalt by synergetic extraction method

A bioleaching and nickel-cobalt technology, applied in the direction of improving process efficiency, can solve the problems of harsh reaction conditions and serious sediment entrainment, and achieve the effects of reducing neutralization costs, reducing nickel-cobalt entrainment losses, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

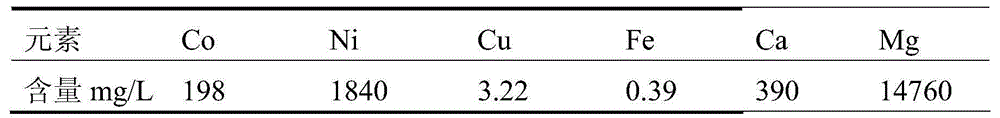

[0021] The method of the present invention is applied to a certain nickel-cobalt ore bioleaching solution, and the composition of the nickel-cobalt bioleaching solution after iron removal is shown in Table 1.

[0022] Table 1 The main components of the leachate after iron removal

[0023]

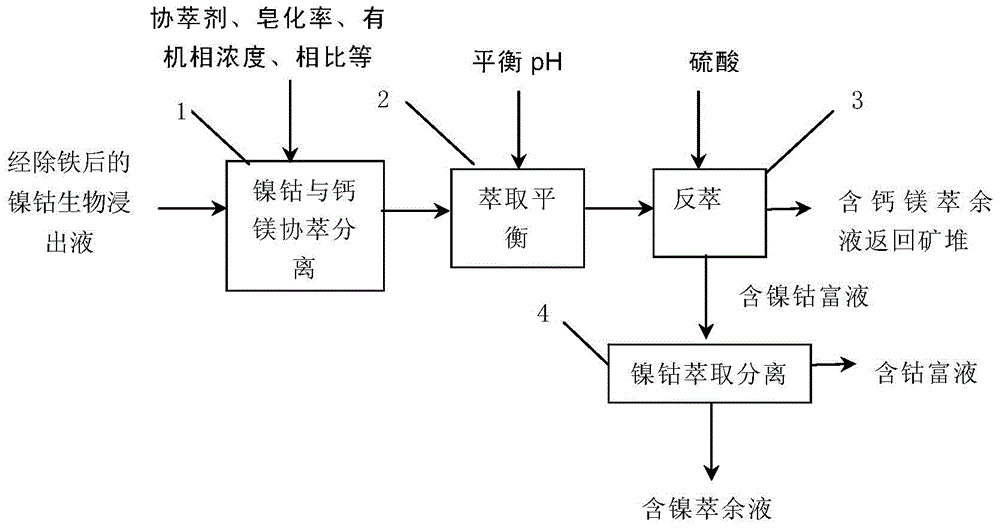

[0024] process such as figure 1 As shown, the specific steps are as follows:

[0025] In step (1), the nickel-cobalt extractant Versatic10 and the co-extractant Cynaex301 are respectively subjected to homogeneous saponification with NaOH solution, the saponification rate is 60%, and the saponification time is 30 minutes;

[0026] In step (2), the organic phase is composed of a combined extractant and diluent MextralDT100, the co-extractant Cynaex301 is 30% (volume fraction), and the extractant Versatic10 is 70% (volume fraction). The combined extractant occupies 10% of the total volume of the organic phase, and the rest is the diluent MextralDT100.

[0027] Step (3), at a temperature ...

Embodiment 2

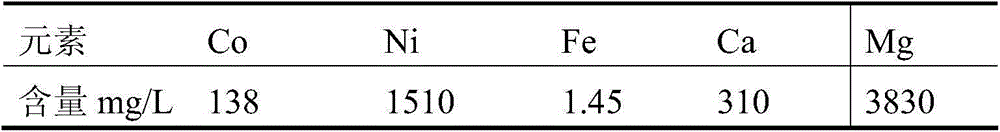

[0030] The method of the present invention is applied to the subsequent purification and removal of impurities from the bioleaching solution of a low-grade nickel-cobalt sulfide ore. The composition of the nickel-cobalt bioleaching solution after iron removal is shown in Table 2.

[0031] Table 2 The main components of the leachate after iron removal

[0032]

[0033] process such as figure 1 As shown, the specific steps are as follows:

[0034] In step (1), the nickel-cobalt extraction agent Versatic10 and the co-extraction agent Cynaex301 are respectively subjected to homogeneous saponification with NaOH solution, the saponification rate is 50%, and the saponification time is 30 minutes;

[0035] In step (2), the organic phase is composed of a combined extractant and diluent MextralDT100, the co-extractant Cynaex301 is 20% (volume fraction), and the extractant Versatic10 is 80% (volume fraction). The combined extractant occupies 20% of the total volume of the organic ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com