Separation and purification device for C8-C20 n-alkane mixed fractions and separation and purification process thereof

A C8-C20, n-paraffin technology, applied in distillation separation, distillation purification/separation, hydrocarbon distillation, etc., can solve the problems of low thermal efficiency, high equipment investment cost, and high energy consumption, and achieve process simplification and reduced energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

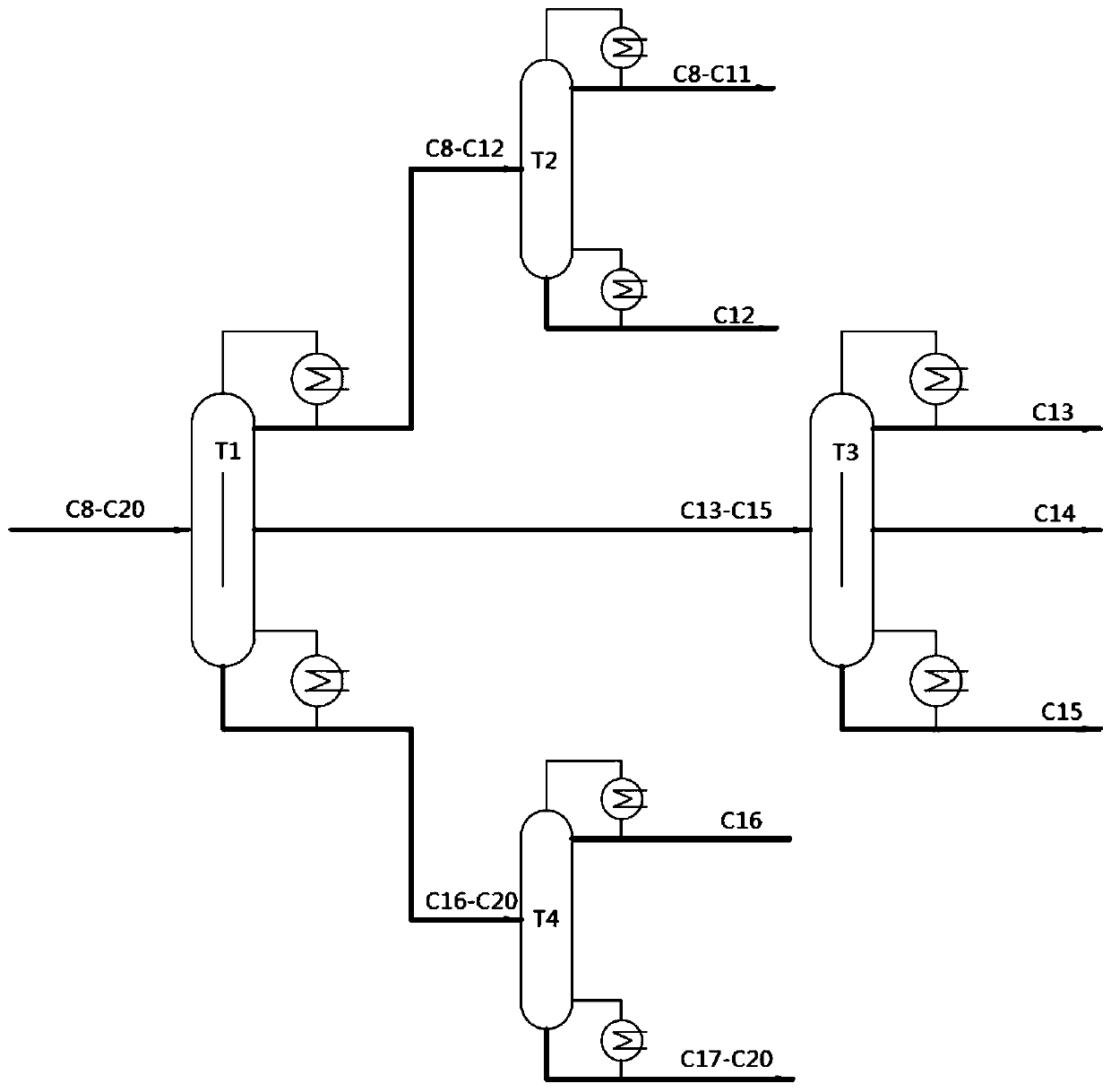

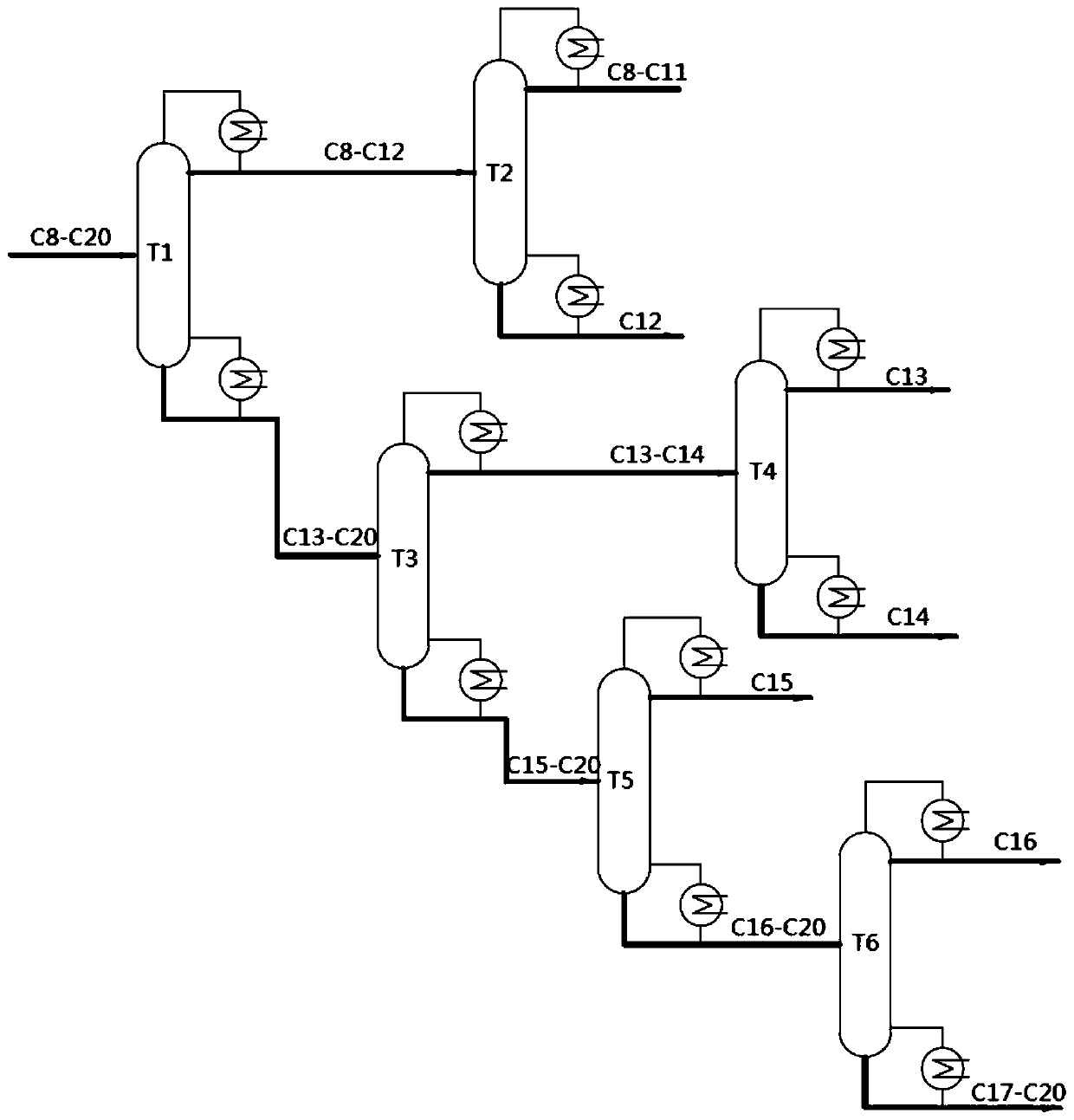

[0047] The traditional process is simplified and transformed by the partition rectification technology, and the C8-C20 mixed fraction in the Fischer-Tropsch synthetic oil is separated by using the process flow integrating the partition rectification tower and the conventional rectification tower. The whole process includes two conventional rectification towers with two partitioned columns, such as figure 1 shown.

[0048] The C8-C20 mixed distillate raw material is fed from the 27th tray of the left pre-fractionation column section of the partitioned rectification column T1 at a mass flow rate of 500kg / h under the state of 135kPa and bubble point temperature. The number of theoretical plates in the partition section of partition rectification column T1 is 60, and the number of theoretical plates in the common rectification column section is 30. The side stream is drawn from the 23rd tray on the right side of the partition, and the common stripping The number of trays was 30. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com