Method for wrapping protection of concrete members in tidal zone

A technology for concrete and tidal range areas, which is applied in the direction of building components, adhesive types, polyether adhesives, etc., and can solve problems such as weather resistance and insufficient durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0055] Processing and preparation of silane-modified polymer sealants.

[0056] Examples 1-4 See Table 1 for the raw material composition and parts by weight of the silane-modified polymer sealant.

[0057] Weigh each material according to the material ratio of the silane-modified polymer sealant example 1-2 in Table 1, first put the silane-modified polymer resin into a clean and dry double planetary mixer, and then add hydrophobic fumed silica , Nano-calcium carbonate, 30-50% by weight of dehydrating agent, vacuumized and stirred at a speed of 50-100rpm for 10-30min; then gradually heated to 50-70°C, and stirred at a high speed of 1000-1500rpm for 30- After 90 minutes, until the sealant colloid is fine and uniform, cool it down to below 40°C; then add the remaining dewatering agent, continue to stir in vacuum, below 40°C, at a speed of 200-300rpm for 10-20min, then add the adhesion promoter. Vacuum, below 40°C, stirring at 200-300rpm for 10-20min; finally add organotin catalys...

Embodiment 5

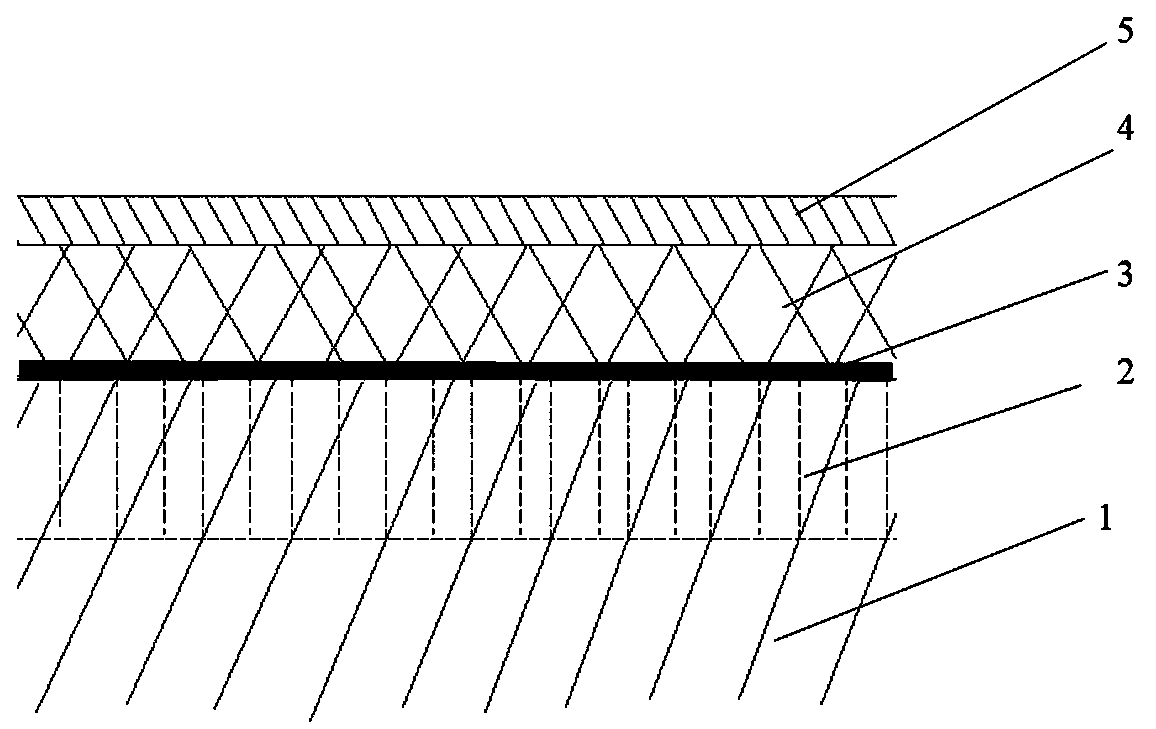

[0063] A wrapping protection method for concrete members in the tidal range area, the wrapping protection structure is as follows figure 1 As shown, wherein, the concrete member matrix 1, the surface of the concrete member matrix 1 is painted with a silane impregnated layer 2, the silane impregnated layer 2 penetrates into the interior of the concrete member matrix 1, the surface of the silane impregnated layer 2 is painted with a primer coating 3, the primer The surface of the coating layer 3 is coated with a silane-modified polymer sealant layer 4 , and the surface of the silane-modified polymer sealant layer 4 is wrapped with a PVF tape wrapping layer 5 .

[0064] The wrapping protection method for concrete members in the tidal range area of the present invention comprises the following steps:

[0065] The first step, substrate treatment

[0066] Use high-pressure fresh water, sandblasting or manual grinding to clean up the floating ash, laitance, slag, moss and loose pa...

Embodiment 6

[0078] On the basis of Example 5, scraping the silane-modified polymer sealant can work underwater if necessary, and the specific steps are as follows:

[0079] Use manual or mechanical grinding methods to clean the surface floating ash, laitance, slag inclusions, moss, marine organisms and loose parts at the lower limit of the tidal range of the concrete component matrix or within the range of 300mm underwater, and ensure that the surface of the concrete component matrix is clean and firm , the surface treatment of the concrete member base includes the remaining pits, grooves, cracks and misalignment;

[0080] Scrape coating of the silane-modified polymer sealant can be done by using a glue gun or a scraper scraper to quickly beat or scrape the silane-modified polymer sealant onto the concrete surface, and apply it slowly, at a constant speed, by pressing, Just scrape it on the surface of the concrete member base, and fill the pits, grooves, cracks and staggered platforms l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com