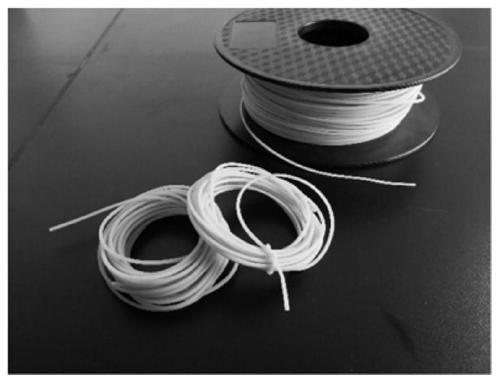

Brominated butyl rubber/polypropylene thermoplastic vulcanized rubber with low hardness and capability of 3D printing and preparation method and application thereof

A technology of bromobutyl rubber and thermoplastic vulcanizate, which is applied in the field of materials, can solve problems such as uneven crosslink density distribution of products, no thermoplastic vulcanizate, complex process, etc., to avoid early vulcanization, small thickness, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

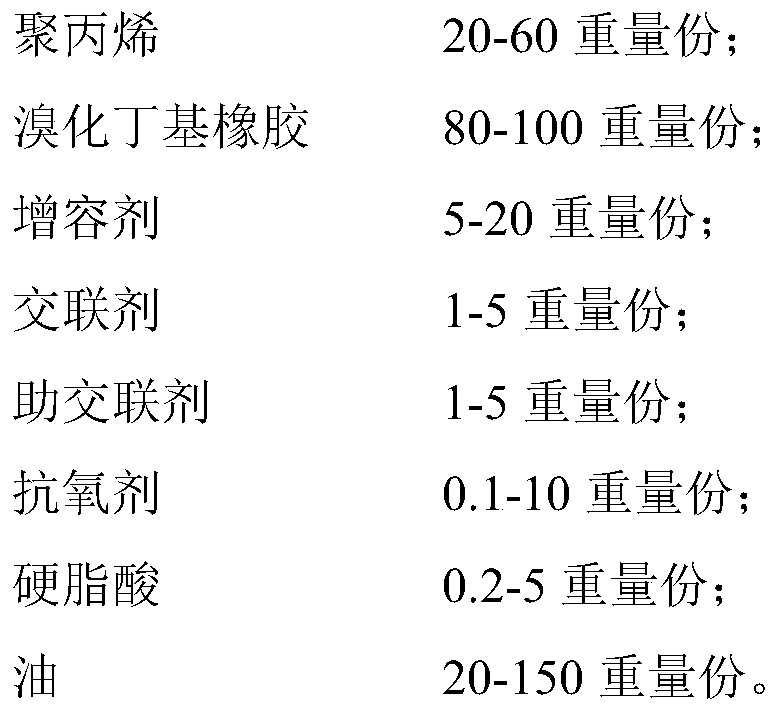

[0059] 1. A bromobutyl rubber / polypropylene thermoplastic vulcanizate, which is made from raw materials comprising the following components:

[0060]

[0061] 2. the preparation method of above-mentioned brominated butyl rubber / polypropylene thermoplastic vulcanizate comprises the following steps:

[0062] Rubber granulation: Bromobutyl rubber (100 parts by weight) is granulated, and the granulation method includes: The method of granulating bromobutyl rubber includes: at 120 ° C, bromobutyl rubber is processed by a single screw Extruded by an extruder, cut into round or square pellets by a pelletizing knife; the average particle size of the obtained rubber particles is 4mm;

[0063] Oil filling: set the temperature of the internal mixer to 50°C and the rotational speed to 60rpm, add rubber particles into the internal mixer, then add N, N'-m-phenylene bismaleimide (4 parts by weight), zinc oxide ( 2.7 parts by weight), antioxidant 1010 (1.5 parts by weight) and stearic aci...

Embodiment 2

[0073] 1. A bromobutyl rubber / polypropylene thermoplastic vulcanizate, which is made from raw materials comprising the following components:

[0074]

[0075] 2. The preparation method of the above-mentioned bromobutyl rubber / polypropylene thermoplastic vulcanizate: except that the weight ratio of each raw material is different, the rest are the same as in Example 1.

[0076] 3. Performance testing

[0077] The mechanical and elastic properties of the BIIR / PP TPV elastomer material prepared above were tested: the method was the same as in Example 1. The results are shown in Table 1.

Embodiment 3

[0079] 1. A bromobutyl rubber / polypropylene thermoplastic vulcanizate, which is made from raw materials comprising the following components:

[0080]

[0081]

[0082] 2. The preparation method of the above-mentioned bromobutyl rubber / polypropylene thermoplastic vulcanizate: except that the weight ratio of each raw material is different, the rest are the same as in Example 1.

[0083] 3. Performance testing

[0084] The mechanical and elastic properties of the BIIR / PP TPV elastomer material prepared above were tested: the method was the same as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com