Temperature-sensitive polyurethane-acrylic resin and its preparation method and hot-melt adhesive film

An acrylic resin and polyurethane technology, used in the field of polymer adhesives, can solve the problems of inability to be used as adhesives, high melting point of waterproof and moisture-permeable films, poor thermal insulation of clothing, etc., to achieve easy industrialization, excellent moisture permeability, excellent permeability The effect of wetness and temperature denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

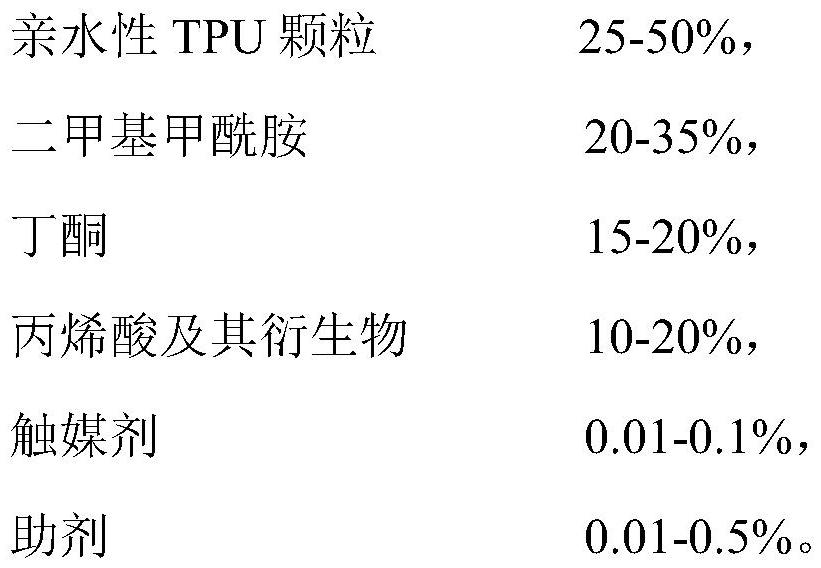

Method used

Image

Examples

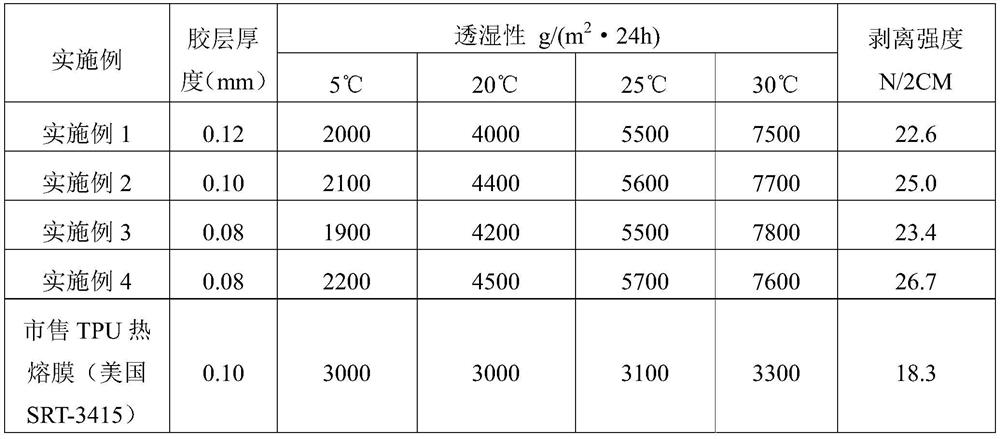

Embodiment 1

[0050] With the dimethylformamide of 25Kg, the methyl ethyl ketone of 20Kg, the hydrophilic polyethylene glycol of 35Kg and phthalic anhydride polyester diol copolymerization type (PEG+PA) polyester TPU particle (melt mass flow rate is 45g / 10 Minutes, the melt viscosity is 14000mPa.s) into the reactor together, heated to 60 ° C, heated and stirred for 1 hour to dissolve, then 20Kg of methacrylic acid and 0.02Kg of catalyst diacyl peroxide were added into the kettle together, Carry out the first polymerization reaction at 60°C, react for 0.5 hours and then add the remaining 0.05Kg of catalyst diacyl peroxide (diluted with 0.3Kg of methyl ethyl ketone and add it to the reactor, and add it within 2 hours) ), continue to react for 3 hours, and the temperature in the kettle is controlled at about 80°C. After the reaction is completed, add 0.03Kg of antioxidant 1010, 0.03Kg of ultraviolet absorber UV-328, 3Kg of nano-titanium dioxide and antimony trioxide mixture to obtain a thermos...

Embodiment 2

[0053] With the dimethylformamide of 35Kg, the methyl ethyl ketone of 15Kg, the hydrophilic polyethylene glycol of 40Kg and adipic acid (AA) series polyester diol copolymerization polyester type TPU particle (melt mass flow rate is 40g / 10 minutes, the melt viscosity is 10000mPa.s) into the reaction kettle together, heated up to 60 ℃, heated and stirred to dissolve for 1 hour, then 10Kg of ethyl acrylate and 0.01Kg of catalyst azobisisobutyronitrile were added together In the kettle, carry out the first polymerization reaction at a temperature of 60°C, add the remaining 0.03Kg catalyst azobisisobutyronitrile (diluted with methyl ethyl ketone and add to the reaction kettle after 0.5 hours) by adding dropwise. After the internal addition) continue to react for 3 hours, and the temperature in the kettle is controlled at about 80°C. After the reaction is completed, add 0.03Kg of antioxidant 1010, 0.03Kg of ultraviolet absorber UV-5411, 2Kg of nano-titanium dioxide and antimony trio...

Embodiment 3

[0056] With the dimethyl formamide of 33Kg, the methyl ethyl ketone of 15Kg, the hydrophilic polyethylene glycol of 40Kg and the polyester type TPU particle (melt mass flow rate is 35g) of adipic acid (AA) series polyester diol copolymerization / 10 minutes, the melt viscosity is 15000mPa.s) together into the reactor, heated to 55 ℃, heated and stirred to dissolve for 1 hour, the mixture of 12Kg of methyl acrylate and acrylamide, 0.02Kg of the catalyst azobisiso Add butyronitrile together in the kettle, carry out the first polymerization reaction under 60 ℃ of temperature, add remaining 0.03Kg catalyst agent azobisisobutyronitrile (diluted with methyl ethyl ketone and add reaction In the still, add within 2 hours) continue to react for 5 hours, and the temperature in the kettle is controlled at about 75°C. After the reaction is completed, add 0.03Kg of antioxidant 168, 0.05Kg of ultraviolet absorber UV-9, 8Kg of nano-titanium dioxide And the mixture of antimony trioxide to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com