3D printed bismaleimide ink and preparation method and application thereof

A bismaleimide, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of large dimensional shrinkage, no bismaleimide resin, and low printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of 3D printing bismaleimide ink, comprises the following steps:

[0034] (1) Prepolymerizing bismaleimide and 2,2'-diallyl bisphenol A to obtain a prepolymer;

[0035] (2) The prepolymer is mixed with a reactive diluent and a photoinitiator to obtain a 3D printing bismaleimide ink.

[0036] In the invention, bismaleimide and 2,2'-diallyl bisphenol A are prepolymerized to obtain a prepolymer. In the present invention, the bismaleimide is preferably N,N'-(4,4'-methylenediphenyl)bismaleimide, N,N'-m-phenylene bismaleimide One or more of imide, N,N'-(1,4-phenylene)bismaleimide; said bismaleimide and 2,2'-diallyl The mass ratio of bisphenol A is preferably 100:(50-100), more preferably 100:(60-80). In the ink system of the present invention, the bismaleimide is still a relatively high component, which can ensure high heat resistance.

[0037] In the present invention, the temperature of the prepolymerization reaction is...

Embodiment 1

[0054] Mix 32g of N,N'-(4,4'-methylenediphenyl)bismaleimide with 24g of 2,2'-diallyl bisphenol A and stir at 140°C for 20 minutes to obtain Uniform and transparent prepolymer. Then add 24g of N-vinylpyrrolidone and continue to stir. After cooling to room temperature, add 0.8g of IR819 and stir well to remove air bubbles, and the final 3D printing bismaleimide ink can be obtained.

[0055] The prepared 3D printing bismaleimide ink is cured by ultraviolet light to obtain a pre-cured product, and the pre-cured product is thermally cured to obtain a cured product; the light intensity of the ultraviolet light is 100W / cm 2 , the UV curing time is 5min, and the heat curing process is 150°C / 2h+180°C / 2h+240°C / 4h.

[0056] Performance testing:

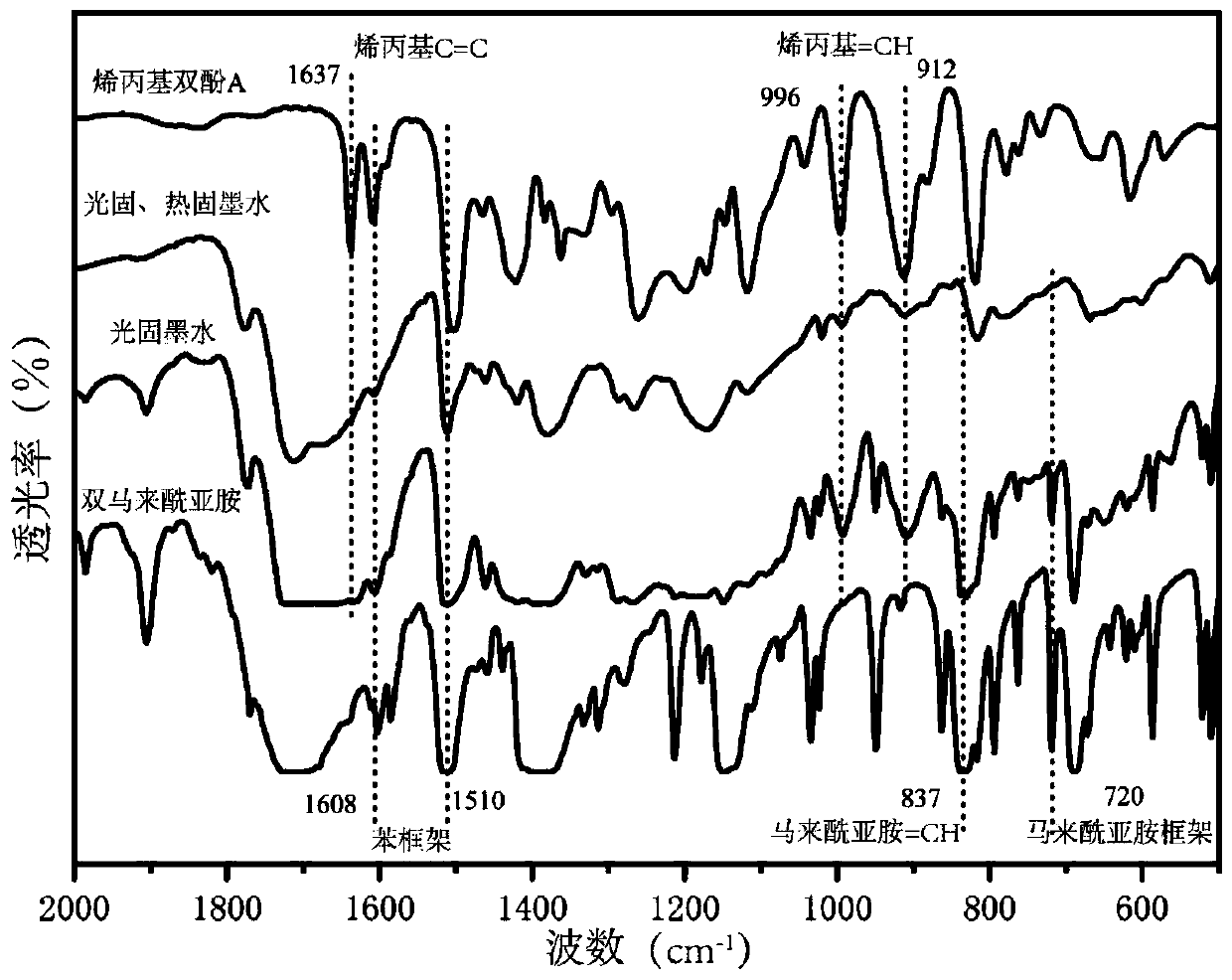

[0057] Infrared spectrum test: N, N'-(4,4'-methylene diphenyl) bismaleimide, 2,2'-diallyl bisphenol A, pre-cured and cured products Infrared test, the obtained IR spectrum is as follows figure 1 shown; from figure 1 It can be seen that, com...

Embodiment 2

[0066] Mix 10g of N,N'-(4,4'-methylenediphenyl)bismaleimide with 7.5g of 2,2'-diallyl bisphenol A and stir at 140°C for 20 minutes Obtain a uniform and transparent prepolymer; then add 5g of N-vinylpyrrolidone and continue to stir, after cooling to room temperature, add 0.225g of IR819 and stir well, then vacuum treatment and centrifugation to remove air bubbles to obtain 3D printed bismaleimide Amine ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com