Safe high-voltage high-energy-density lithium ion battery and preparation method thereof

A lithium-ion battery, high energy density technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, battery electrodes, etc., can solve the problems of inferior capacity and cycle performance, low first-time efficiency, poor safety and stability of high nickel, etc., to achieve guaranteed Effects of cycle stability, improved stability, and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

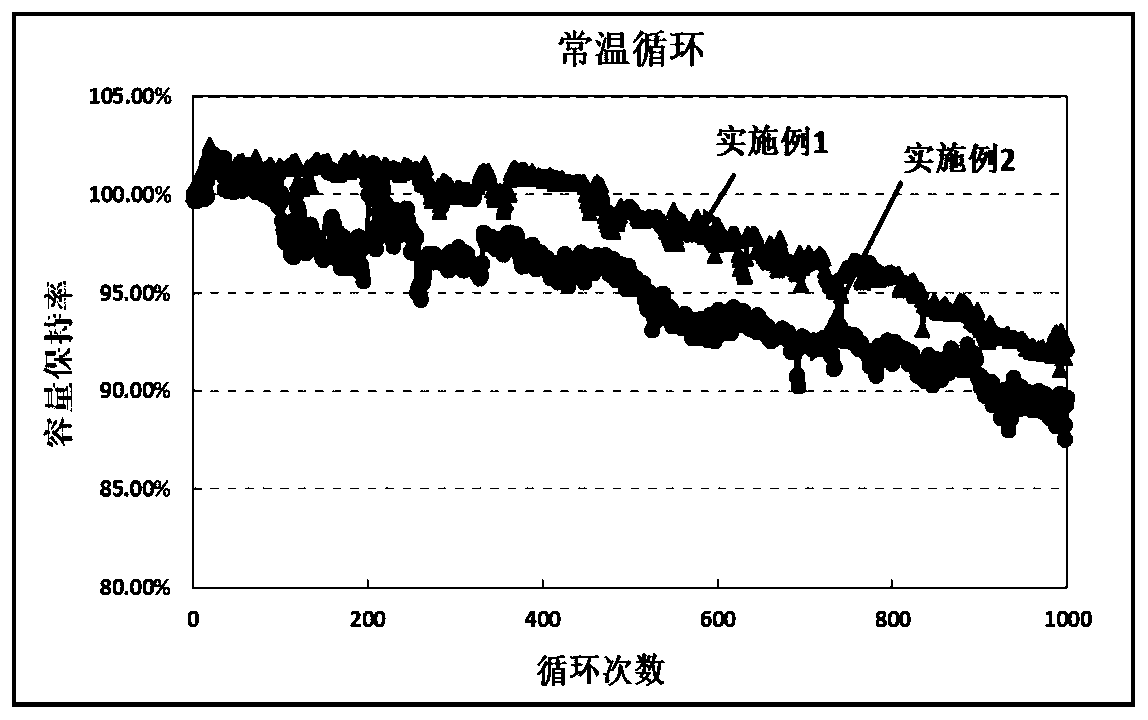

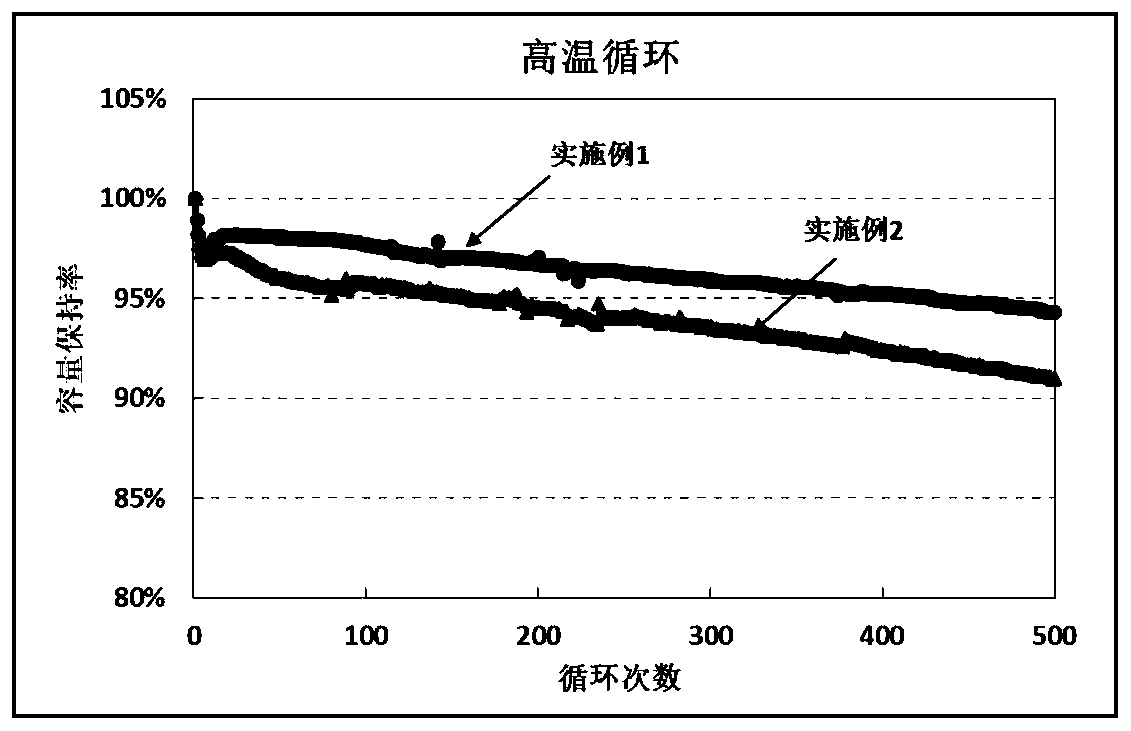

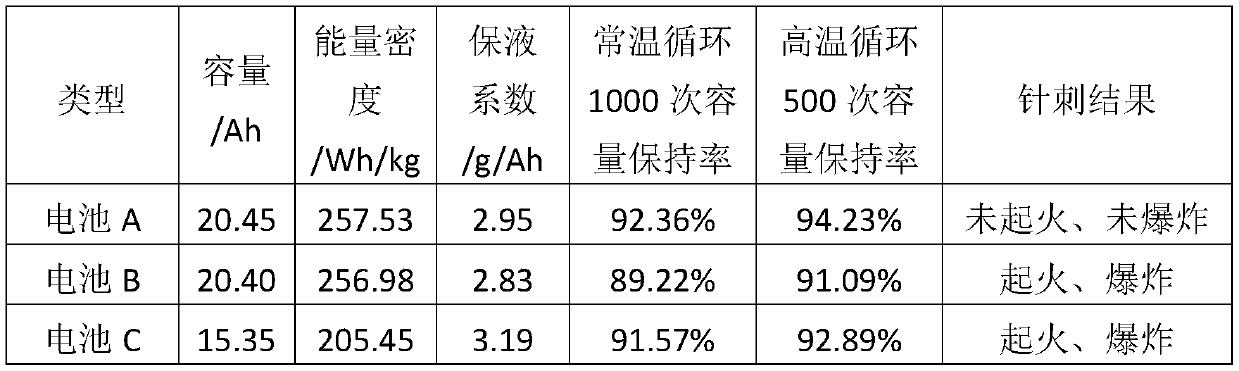

Embodiment 1

[0029] Step S1: Positive electrode sheet preparation

[0030] Dissolve 1.6% polytetrafluoroethylene in N-methylpyrrolidone to form a 6.5% uniformly mixed glue, then add 1.2% conductive carbon black and 0.7% carbon nanotubes, stir for 2 hours, mix well, and then add 30% titanium oxide A mixture of coated single crystal NCM523 (particle size 6 μm) and 66.5% titanium oxide coated single crystal NCM622 (particle size 4 μm) was stirred for 4 hours to obtain positive electrode slurry.

[0031] The above positive electrode slurry was evenly coated on a 12 μm aluminum foil, baked and rolled (compaction density 3.6g / cm 3 ), die-cut to obtain the required positive pole piece.

[0032] Step S2: Negative electrode sheet preparation

[0033] Dissolve 1.2% sodium carboxymethyl cellulose in deionized water to obtain a glue solution with a solid content of 1.3%, add 1.2% conductive carbon black, 95.1% artificial graphite, and 2.5% styrene-butadiene rubber in sequence to obtain the negative ...

Embodiment 2

[0038] Step S1: Positive electrode sheet preparation

[0039] Dissolve 1.6% polytetrafluoroethylene in N-methylpyrrolidone to form a 6.5% uniformly mixed glue, then add 1.2% conductive carbon black and 0.7% carbon nanotubes, stir for 2 hours, mix well, and then add 30% titanium oxide A mixture of coated single crystal NCM523 (particle size 6 μm) and 66.5% titanium oxide coated single crystal NCM622 (particle size 4 μm) was stirred for 4 hours to obtain positive electrode slurry.

[0040] The above positive electrode slurry was evenly coated on a 12 μm aluminum foil, baked and rolled (compaction density 3.6g / cm 3 ), die-cut to obtain the required positive pole piece.

[0041] Step S2: Negative electrode sheet preparation

[0042] Dissolve 1.2% sodium carboxymethyl cellulose in deionized water to obtain a glue solution with a solid content of 1.3%, add 1.2% conductive carbon black, 95.1% artificial graphite, and 2.5% styrene-butadiene rubber in sequence to obtain the negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com