A kind of preparation method of molybdenum oxide/molybdenum disulfide core-shell microsphere

A technology of molybdenum disulfide and core-shell microspheres, which can be used in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc., can solve the problems of hazards to workers and the environment, complex processes, and difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of molybdenum oxide / molybdenum disulfide core-shell microspheres, comprising the following steps:

[0027] (1) Put the sodium molybdate powder in a tube furnace, and perform high-temperature oxidation and calcination in the air atmosphere for 2 hours to obtain molybdenum oxide particles. The heating rate during the high-temperature calcination process is 10°C / min, and the calcination temperature is 400°C;

[0028] (2) Add urea and tetrathioacetamide to ethanol at a mass ratio of 1:0.3, stir for 20 mins until clarification, then add the molybdenum oxide particles obtained in step (1), stir evenly with ultrasonic, then transfer to hydrothermal reaction In the kettle, hydrothermal synthesis was carried out at 180°C for 24h;

[0029] (3) The reaction product was centrifuged, washed three times with ethanol and deionized water, and vacuum-dried at 60°C for 12 hours to obtain molybdenum oxide / molybdenum disulfide core-shell microspheres.

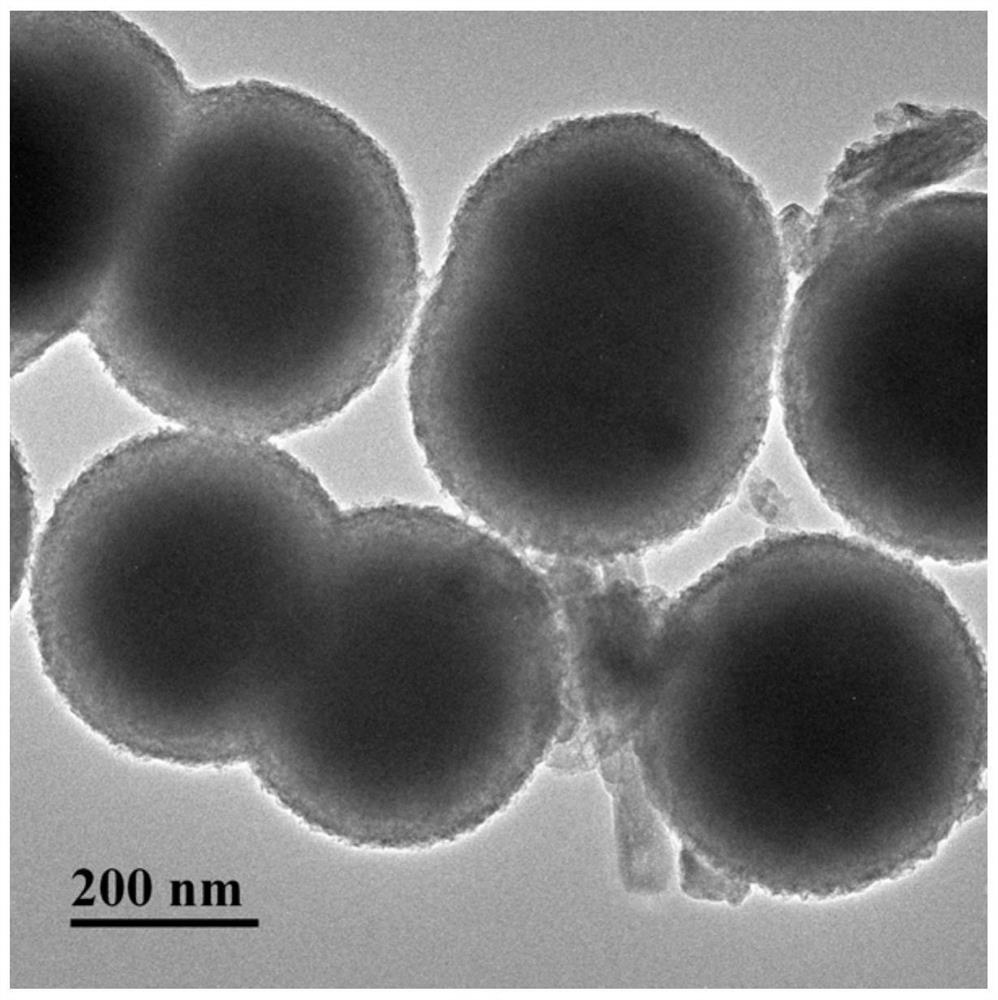

[0030] figure...

Embodiment 2

[0032] A preparation method of molybdenum oxide / molybdenum disulfide core-shell microspheres, comprising the following steps:

[0033] (1) Put the ammonium tetrathiomolybdate powder in a tube furnace, and perform high-temperature oxidation and calcination in the air atmosphere for 2 hours to obtain molybdenum oxide particles. The heating rate of the high-temperature calcination process is 2°C / min, and the calcination temperature is 300°C ;

[0034] (2) Add urea and tetrathioacetamide to ethanol at a mass ratio of 1:0.4, stir for 30 mins until clarified, then add the molybdenum oxide particles obtained in step (1), stir evenly with ultrasonic, then transfer to hydrothermal reaction In the kettle, hydrothermal synthesis was carried out at 180°C for 24h;

[0035] (3) The reaction product was centrifuged, washed three times with ethanol and deionized water, and vacuum-dried at 60°C for 12 hours to obtain molybdenum oxide / molybdenum disulfide core-shell microspheres.

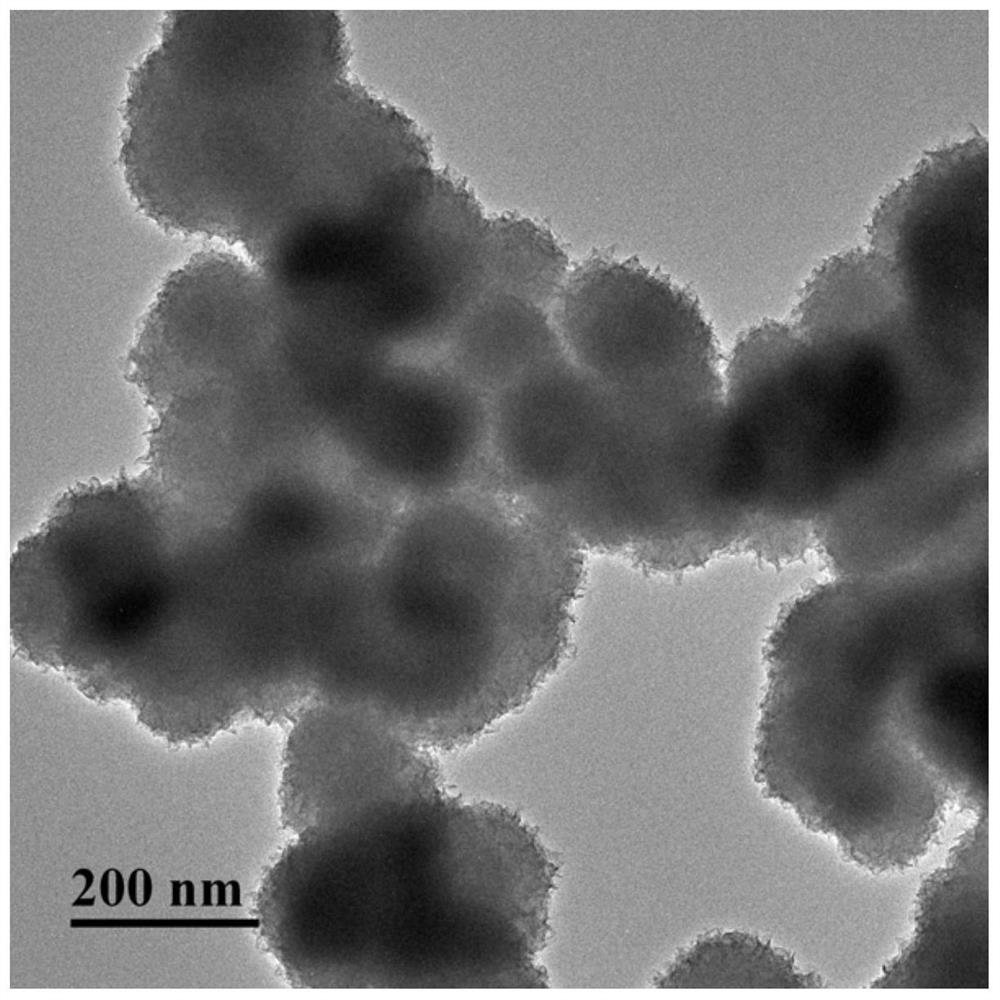

[0036] f...

Embodiment 3

[0038] A preparation method of molybdenum oxide / molybdenum disulfide core-shell microspheres, comprising the following steps:

[0039] (1) Put the ammonium tetrathiomolybdate powder in a tube furnace, and perform high-temperature oxidation and calcination in the air atmosphere for 2 hours to obtain molybdenum oxide particles. The heating rate during the high-temperature calcination process is 10°C / min, and the calcination temperature is 400°C ;

[0040] (2) Add urea and tetrathioacetamide to ethanol at a mass ratio of 1:0.3, stir for 30 mins until clarification, then add the molybdenum oxide particles obtained in step (1), stir evenly with ultrasonic, then transfer to hydrothermal reaction In the kettle, hydrothermal synthesis was carried out at 180°C for 36h;

[0041] (3) The reaction product was centrifuged, washed three times with ethanol and deionized water, and vacuum-dried at 60°C for 12 hours to obtain molybdenum oxide / molybdenum disulfide core-shell microspheres.

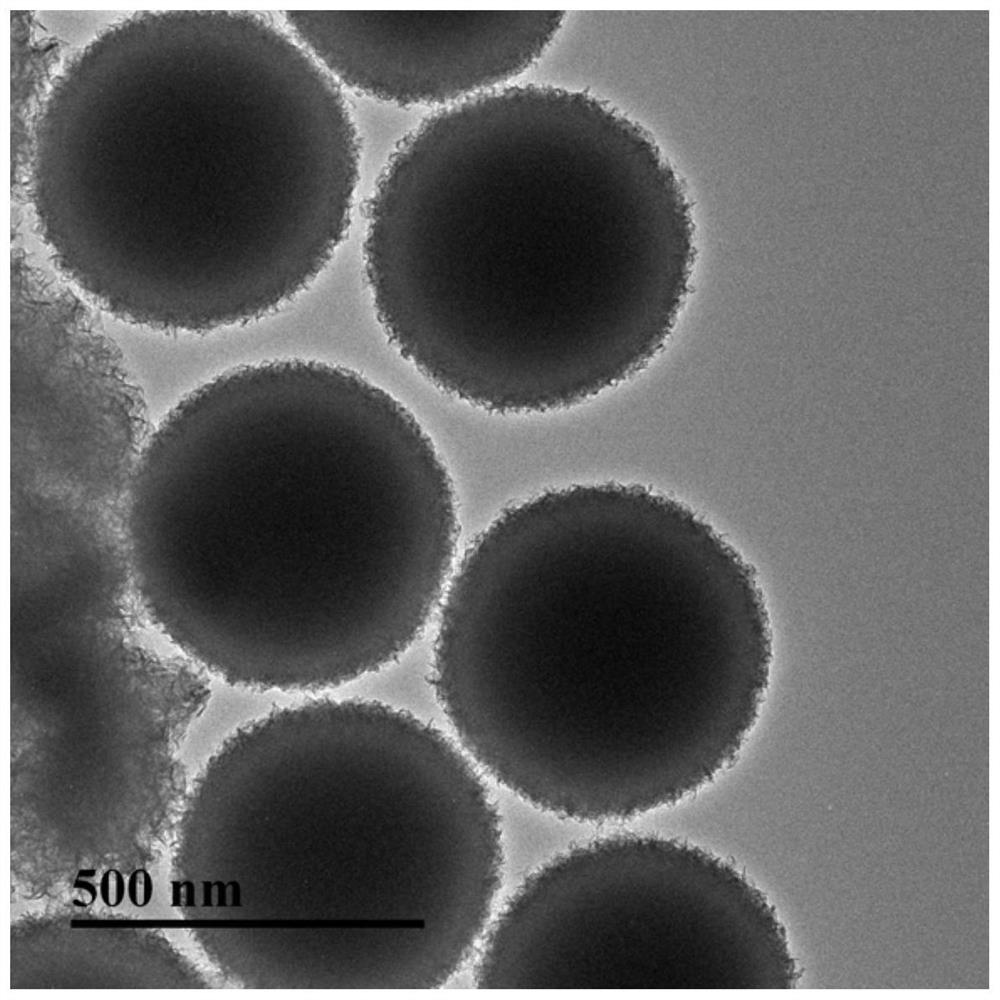

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com