Amino-modified nano-polystyrene and preparation method thereof

An amino-modified, polystyrene technology, applied in the field of amino-modified nano-polystyrene and its preparation, can solve the problems of large particle size and limitation of products, and achieve the effects of less dosage, low cost, and easy availability of medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Amino-modified nano polystyrene is composed of the following components in mass percentage: monomer styrene 8%, dodecylamine hydrochloride 1.5%, azobisisobutylamidine hydrochloride 0.45%, and the balance is water .

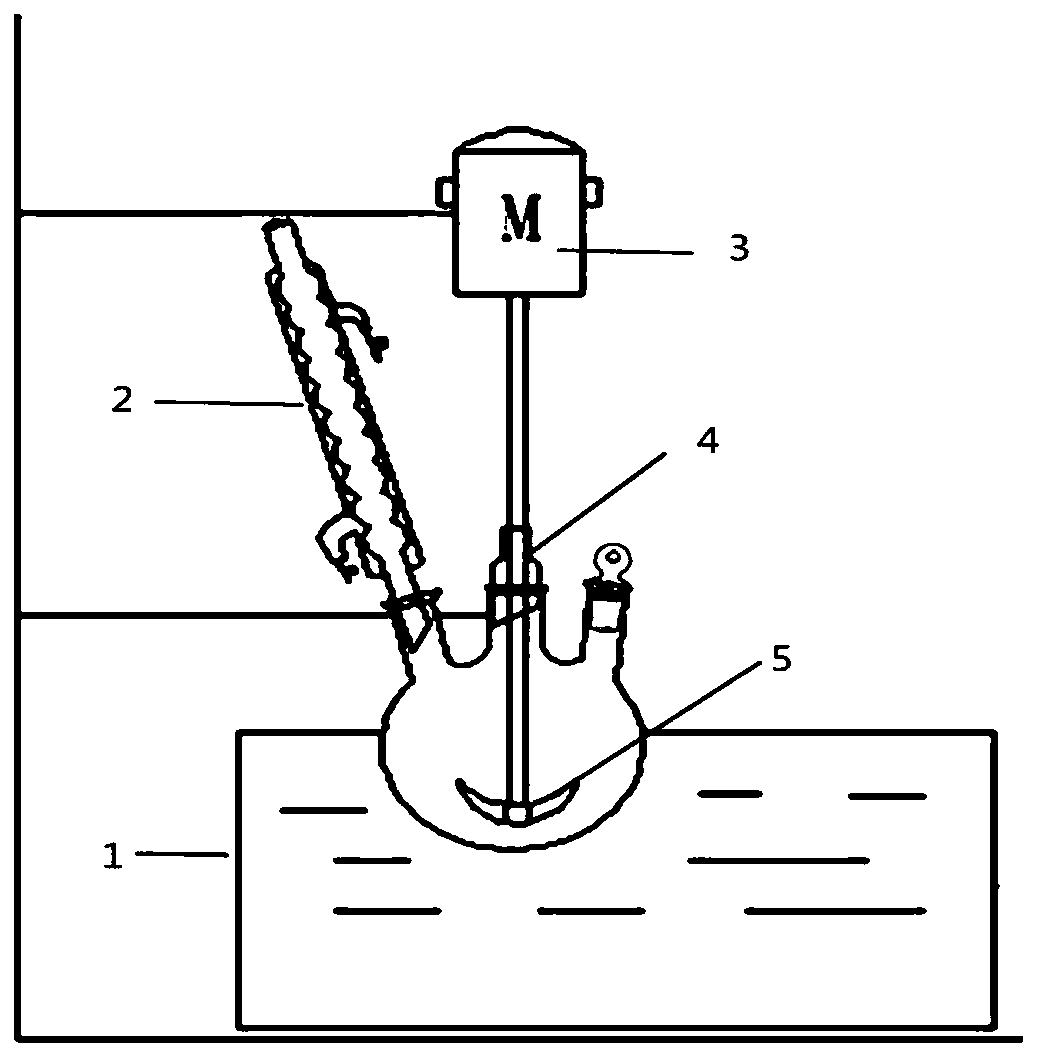

[0031] The preparation method of the nanometer polystyrene of amino modification, comprises:

[0032] 1) Weigh 1.5 g of dodecylamine hydrochloride and 85 g of deionized water, add them into a reaction flask and mix them, the reaction temperature is 75°C, and the stirring speed is 300 rpm;

[0033] 2) Weigh 8g of styrene into the reactor and seal it;

[0034] 3) A mixture of 0.15 g of azobisisobutylamidine hydrochloride and 1.68 g of deionized water was added dropwise when the reaction was carried out for 30 min, 60 min, and 120 min, respectively;

[0035] 4) After the reaction was carried out for 5 hours, the stirring was stopped and cooled to room temperature to obtain amino-modified nano-polystyrene.

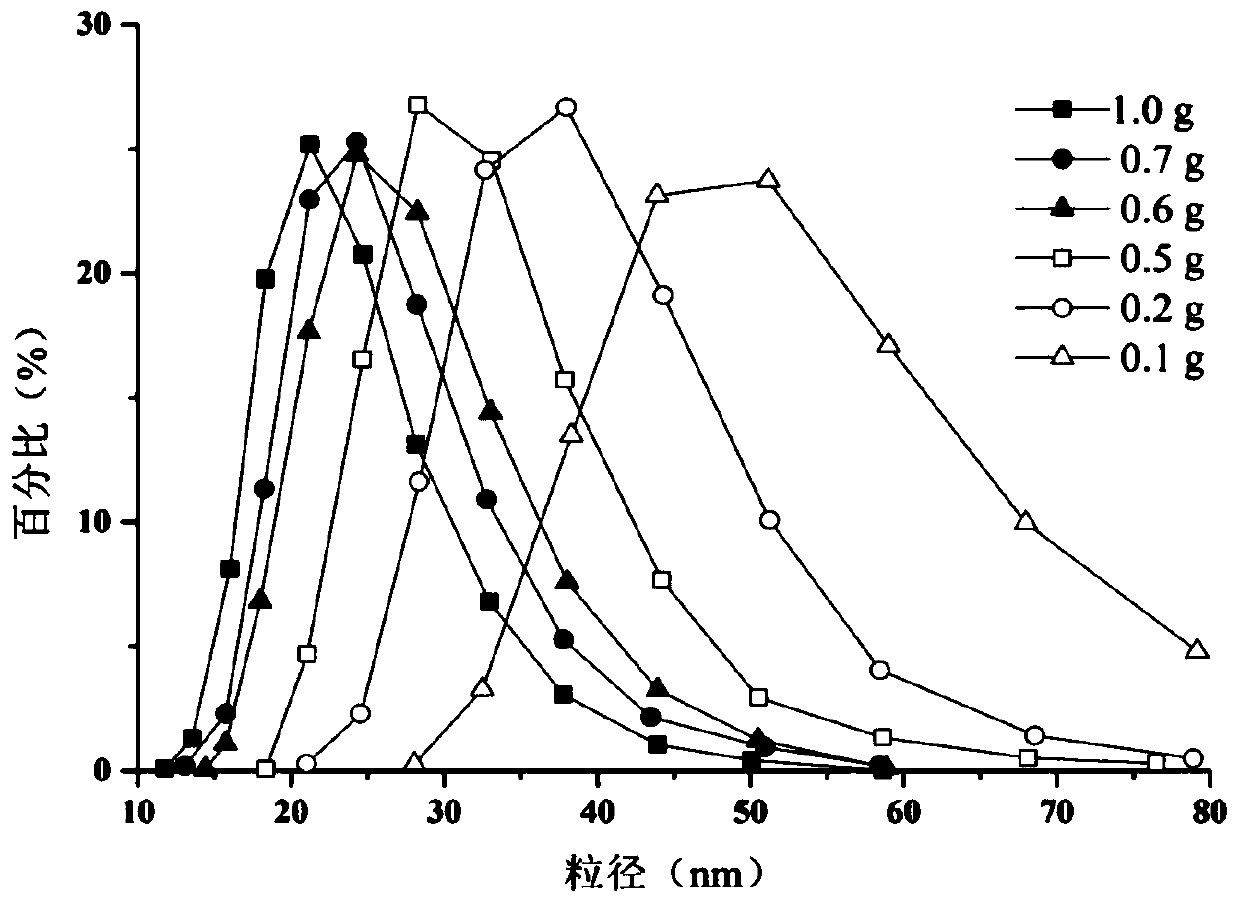

[0036] Such as figure 2 As shown, the amino-modi...

Embodiment 2

[0038] Amino-modified nano polystyrene is composed of the following components in mass percentage: monomer styrene 2%, dodecylamine hydrochloride 1%, azobisisobutylamidine hydrochloride 0.3%, and the balance is water .

[0039] The preparation method of the nanometer polystyrene of amino modification, comprises:

[0040] 1) Weigh 1 g of dodecylamine hydrochloride and 85 g of deionized water, add them to the reaction flask and mix them, the reaction temperature is 75°C, and the stirring speed is 300 rpm;

[0041] 2) Weigh 2 g of styrene into the reactor and seal it;

[0042] 3) A mixture of 0.1 g of azobisisobutylamidine hydrochloride and 3.9 g of deionized water was added dropwise when the reaction was carried out for 30 min, 60 min, and 120 min, respectively;

[0043] 4) After the reaction was carried out for 5 hours, the stirring was stopped and cooled to room temperature to obtain amino-modified nano-polystyrene.

[0044] The amino-modified nano-polystyrene prepared in t...

Embodiment 3

[0046] Amino-modified nano polystyrene is composed of the following components in mass percentage: monomer styrene 5.6%, dodecylamine hydrochloride 0.5%, azobisisobutylamidine hydrochloride 0.36%, and the balance is water .

[0047] The preparation method of the nanometer polystyrene of amino modification, comprises:

[0048] 1) Weigh 0.5 g of dodecylamine hydrochloride and 85 g of deionized water, add them into a reaction flask and mix them, the reaction temperature is 75°C, and the stirring speed is 300 rpm;

[0049] 2) Weigh 6.3g of styrene into the reactor and seal it;

[0050] 3) A mixture of 0.12 g of azobisisobutylamidine hydrochloride and 2.61 g of deionized water was added dropwise when the reaction was carried out for 30 min, 60 min, and 120 min, respectively;

[0051] 4) After the reaction was carried out for 5 hours, the stirring was stopped and cooled to room temperature to obtain amino-modified nano-polystyrene.

[0052] The amino-modified nano-polystyrene pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com