A preparation method and application of rare earth-doped apatite fluorescent nanodots

A fluorescent nano and rare earth doping technology, applied in nanotechnology, nano optics, nanotechnology, etc., can solve the problems of nanoparticle agglomeration, size increase, and impact on the use of fluorescent imaging agents, and achieve reduced agglomeration, uniform size distribution, and good Effects of Aqueous Suspension Stability and Fluorescence Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

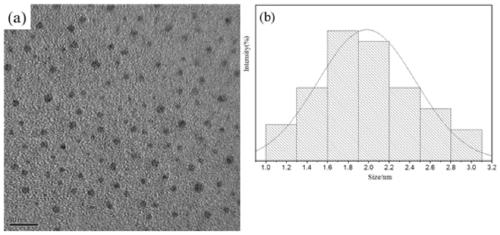

[0028] Prepare 15ml of colloidal solution of polyacrylic acid, calcium ions, and rare earth ions, adjust the pH to 9.0 with ammonia water, and stir for 15 minutes. Among them, Eu 3+ / (Ca 2+ +Eu 3+ ) The mole fraction is 4%. Mix 15ml of phosphate ion solution with the obtained colloidal solution, adjust the pH to 9.7 with ammonia water and stir vigorously for 30min to obtain a milky white suspension. Among them, (Ca 2+ +Eu 3+ ) / P mole fraction is 1.67, carboxylate and (Ca 2+ +Eu 3+ ) The molar ratio is 0.92, (Ca 2+ +Eu 3+ ), PO 4 3- and PAA concentrations were 0.0501M, 0.03M and 4mg / ml, respectively. The obtained milky white suspension was hydrothermally treated at 60° C. for 1 h (the average temperature increase rate was 12° C. / min), centrifuged and washed to rare earth-doped apatite fluorescent nano-dots.

[0029] The rare earth-doped apatite fluorescent nano-dot transmission electron microscope picture and the particle size distribution histogram obtained in this...

Embodiment 2

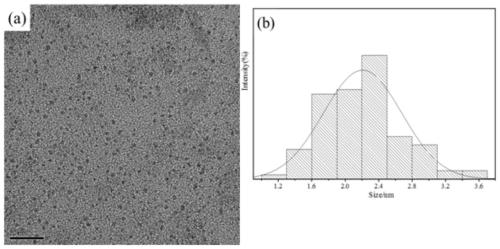

[0031] Prepare 15ml of colloidal solution of polyacrylic acid, calcium ions, and rare earth ions, adjust the pH to 5.0 with ammonia water, and stir for 15 minutes. Among them, Eu 3+ / (Ca 2+ +Eu 3+ ) The mole fraction is 4%. Mix 15ml of phosphate ion solution with the obtained colloidal solution, adjust the pH to 9.7 with ammonia water and stir vigorously for 30min to obtain a milky white suspension. Among them, (Ca 2+ +Eu 3+ ) / P mole fraction is 1.67, carboxylate and (Ca 2+ +Eu 3+ ) The molar ratio is 0.92, (Ca 2+ +Eu 3+ ), PO 4 3- and PAA concentrations were 0.0501M, 0.03M and 4mg / ml, respectively. The obtained milky white suspension was transferred into an autoclave, and subjected to hydrothermal treatment at 180° C. for 1 h (the average temperature increase rate was 5.1° C. / min) to obtain a suspension of rare earth-doped apatite fluorescent nanodots. After centrifugation and washing, the rare earth-doped apatite fluorescent nano-dots are obtained.

[0032] The ...

Embodiment 3

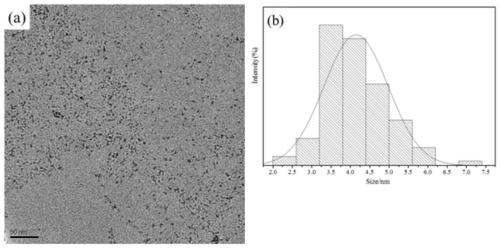

[0034] Prepare 15ml of colloidal solution of polyacrylic acid, calcium ions, and rare earth ions, adjust the pH to 9.0 with ammonia water, and stir for 15 minutes. Among them, Eu 3+ / (Ca 2+ +Eu 3+ ) The mole fraction is 4%. Mix 15ml of phosphate ion solution with the obtained colloidal solution, adjust the pH to 9.7 with ammonia water and stir vigorously for 30min to obtain a milky white suspension. Among them, (Ca 2+ +Eu 3+) / P mole fraction is 1.67, carboxylate and (Ca 2+ +Eu 3+ ) The molar ratio is 0.46, (Ca 2+ +Eu 3+ ), PO 4 3- and PAA concentrations were 0.0501M, 0.03M and 2mg / ml, respectively. The obtained milky white suspension was transferred into an autoclave, hydrothermally treated at 120° C. for 1 h (the average heating rate was 10° C. / min), centrifuged and washed to obtain rare earth-doped apatite fluorescent nanodots.

[0035] The rare earth-doped apatite fluorescent nano-dot transmission electron microscope picture and the particle size distribution hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com