Polyester chip for producing compound filament with ultralow melting point and preparation method thereof

A technology of polyester chips and composite filaments, applied in the direction of single-component copolyester rayon filaments, etc., can solve the problems of unfavorable drying crystallization treatment, wide amorphous area, unstable extrusion pressure, etc., and achieve the solution of subsequent crystallization. Difficulty, reducing agglomeration, high firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The polyester chip preparation method for producing ultra-low melting point composite filaments of the present invention comprises the following steps:

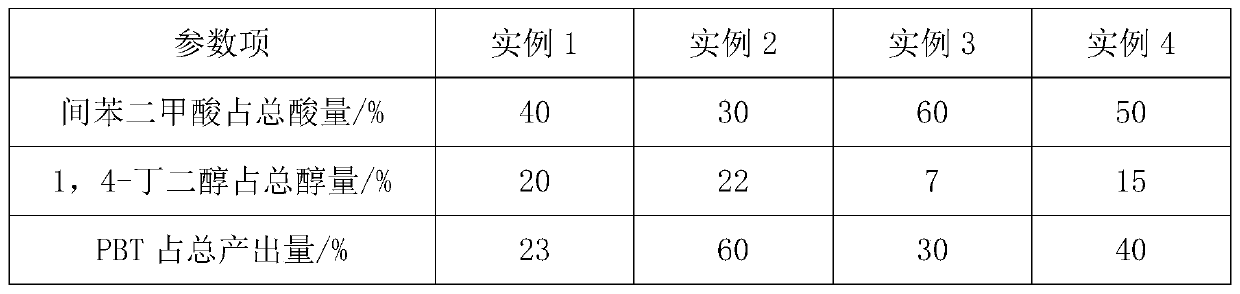

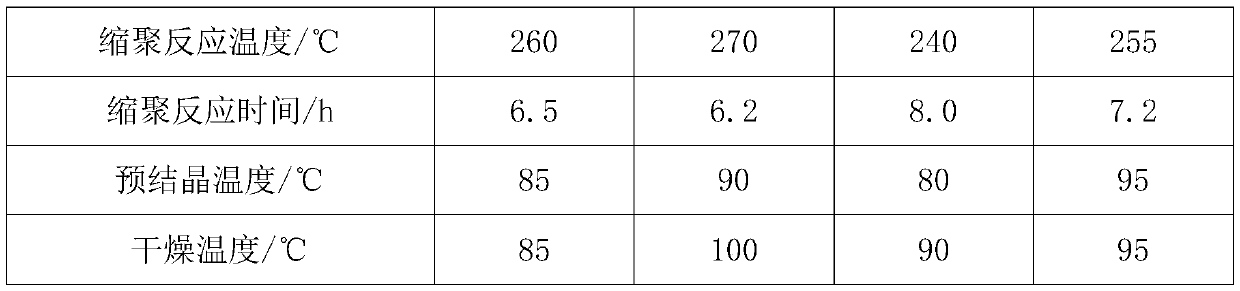

[0024] (1) Synthesis of ultra-low melting point polyester chip bottom material: ① Put the mixture of isophthalic acid and terephthalic acid into the mixed solution of 1,4-butanediol and ethylene glycol, in which isophthalic acid accounts for The mass fraction of the mixture is 30%-60%, 1,4-butanediol accounts for 7%-22% of the total alcohol moles, and the mixed slurry is evenly pumped into the first esterification reaction tank through the delivery pump, Prepare a homogeneous slurry of BHET and its derivative intermediates; ② Add PBT and auxiliary materials to the diesterification reactor. The mass of PBT accounts for 30%-60% of the total mass of the final polyester chips. Alcoholysis, the mixed alcohol molar ratio is EG: BDO = 4: 1, and a uniform molten slurry is obtained; ③ When the temperature of the slurry in step ...

Embodiment 1

[0044] ①One esterification reaction stage: add 40% isophthalic acid and 60% terephthalic acid (percentage is mole fraction, the same below) to the slurry mixing tank, totaling 2 tons, and then according to the acid-alcohol molar ratio Add ethylene glycol and 1,4-butanediol at a ratio of 1:1.24, the molar ratio of ethylene glycol and 1,4-butanediol is 4:1, after mixing evenly, pump it into the primary esterification reaction kettle at a constant speed through a pipeline pump, The esterification reaction was carried out at 255°C to obtain a homogeneous mixed slurry of BHET and its derivatives.

[0045] ②Put 700Kg of PBT polyester chips, 300g of antimony trioxide, 300g of butyl titanate, 1000g of antioxidant, 2g of dye into the diesterification reactor, and add 200Kg of ethylene glycol in a molar ratio: 1,4- The mixed alcohol of butanediol=4:1 carries out the alcoholysis reaction, after the alcoholysis of the diester is completed, it is mixed with the monoesterification slurry, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com