Method for preparing polyacrylonitrile resin for carbon fiber by adopting aqueous phase precipitation continuous polymerization process

A technology of polyacrylonitrile resin and polymerization process, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc. It can solve problems such as production efficiency decline, product quality impact, production difficulties, etc., and achieve uniform temperature field, perfect particle structure, and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

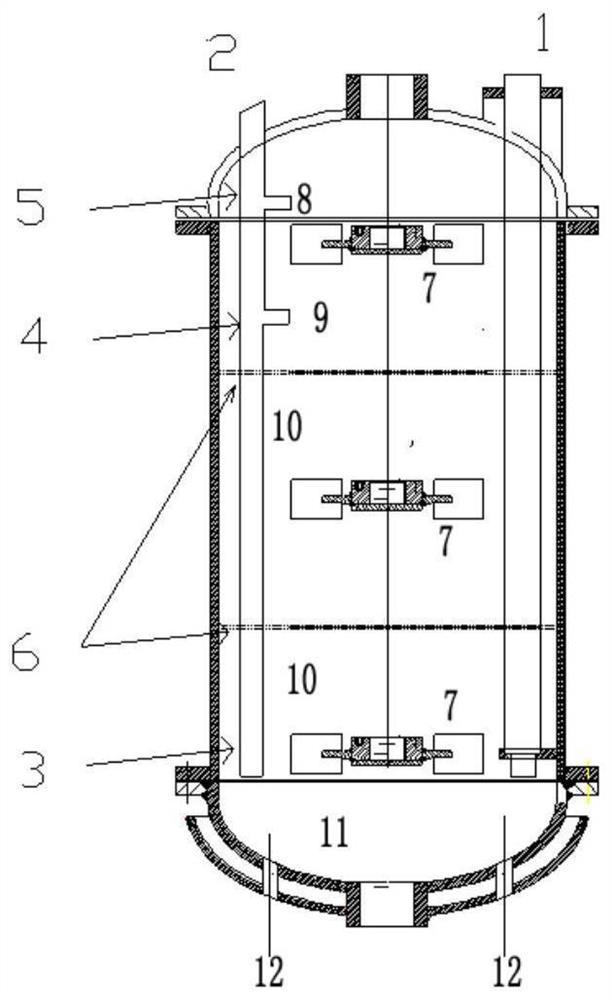

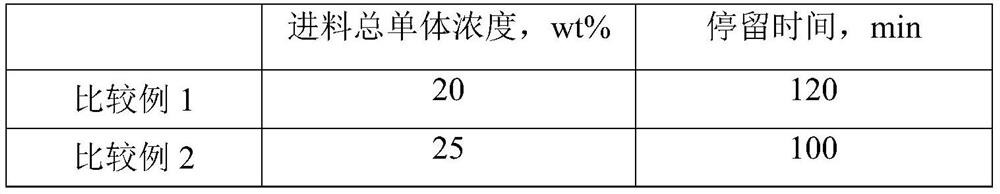

[0028] Acrylonitrile is used as the first comonomer, the second and third comonomers are methyl acrylate and itaconic acid respectively, the weight ratio of acrylonitrile, methyl acrylate and itaconic acid is 96:3:1, and the oxidizing agent It is sodium chlorate, and the reducing agent is sodium metabisulfite. Based on the total polymerization feed monomers, the amount of initiator was 0.32wt%, and the reaction temperature was controlled at 53°C for copolymerization reaction. The concentration of total feed monomers and polymerization reaction time are shown in Table 1. The pure water in the polymerization reactor is fed in three ways. The amount of pure water in the bottom channel makes the total polymerization feed monomer concentration reach the control range, the amount of pure water in the mixing zone 9 makes the solid content of the material in the mixing zone 9 reach 20%, and the amount of pure water in the discharge zone 8 makes the solid content of the material in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com