A hydrogenation catalyst and a preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of catalyst pore size and small pore volume, and achieve reaction The effect of short time, high continuous process efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example introduces the preparation method of Mo and Ni original solutions. In this embodiment, each Mo and Ni acidic active metal solution A1 and basic active metal solution B1 were prepared with one concentration and ratio, and solutions with other ratios and concentrations can be prepared according to this method.

[0046] Configuration of acidic active metal solution A1: Take 386g of molybdenum oxide and 123g of basic nickel carbonate into a multi-necked flask, add a certain amount of deionized water, stir until the substance in the bottle is slurry, then slowly add 86g of phosphoric acid, After the initial reaction, heat slowly, keep the solution temperature at 90-110°C for 1-3 hours, stop heating, filter the obtained solution while it is hot, and then add phosphoric acid to adjust the pH value of the solution to 1.0-4.0 to obtain Clear acidic reactive metal solution A1. The solution composition is MoO 3 NiO: 69.27g / 100mL; NiO: 12.49g / 100mL.

[0047] Configu...

Embodiment 2

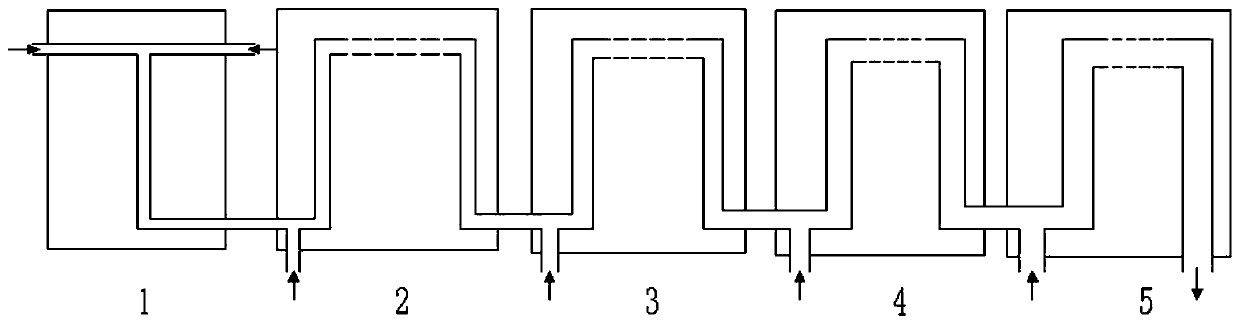

[0049] NaAlO with a concentration of 50g / 100mL 2 Alkaline material of solution and alkaline active metal solution B1 with Al concentration of 80g / 100mL 2 (SO 4 ) 3 solution and the acidic material of the acidic active metal solution A1 are added to their respective component tanks, each raw material tank and the first impingement flow microreactor are placed in an oil bath and heated to 90°C, and the booster of the two component tanks is turned on. Press the pump, and enter the alkaline material and the acidic material into the first impact flow reactor through the atomizer at the same time, control the flow rate of the alkaline material to 15mL / min, adjust the pH value in the impact flow reactor to 8.5, and neutralize Precipitation reaction, the reaction mixture stays in the first impingement flow microreactor for 1min and then enters the second microreactor; microwave heating is used to raise the reaction temperature of the second microreactor to 110°C, and the second micr...

Embodiment 3

[0051] NaAlO with a concentration of 80g / 100mL 2 solution and alkaline active metal solution B2 (MoO3 : 50.2g / 100mL; NiO: 10.1g / 100mL) alkaline material and Al with a concentration of 100g / 100mL 2 (SO 4 ) 3 solution and 45g / 100mL acidic active metal solution A2 (MoO 3 : 40.7g / 100mL; NiO: 11.5g / 100mL) acidic materials were added to their respective component tanks, each raw material tank and the first impingement flow microreactor were put into an oil bath and heated to 80°C, and the two The booster pump of a component tank simultaneously enters the acidic material and the alkaline material into the first impact flow reactor through the atomizer, controls the flow rate of the alkaline material to be 15mL / min, and adjusts the pH in the impact flow reactor. When the value is 9.0, the neutralization precipitation reaction is carried out, and the reaction mixture stays in the first impingement flow microreactor for 1.5 minutes and then enters the second microreactor; microwave h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com