A high-temperature and high-pressure preparation method of single-phase nanocubic-titanium boride

A high-temperature, high-pressure, nano-cubic technology is applied in the high-temperature and high-pressure preparation of a single-phase cubic-titanium boride, and the regulation of nanoscale grains. Effect of reaction time and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] High-purity titanium powder (Ti) with a particle size of 50 to 100 nanometers and boron powder (B) with a particle size of 100 to 200 nanometers are mixed according to a molar ratio of 1:0.8, and the raw materials of the mixture are pressed by a hydraulic press according to the size of the synthesis cavity. Into a cylindrical shape (diameter 4mm, height 2.5mm), after the sample is pressed and formed, it is put into a synthesis chamber, and a six-sided hydraulic press is used to provide a high-temperature and high-pressure environment to synthesize the sample. In order to ensure the uniformity of the temperature of the synthesis chamber during the process of synthesizing the sample, the graphite heat pipe is used for side heating in the assembly chamber. At the same time, in order to ensure that the sample does not react with the heated graphite tube, the chamber of the synthesis sample is made of hexagonal boron nitride. Protect. The synthesis pressure is controlled to ...

Embodiment 2

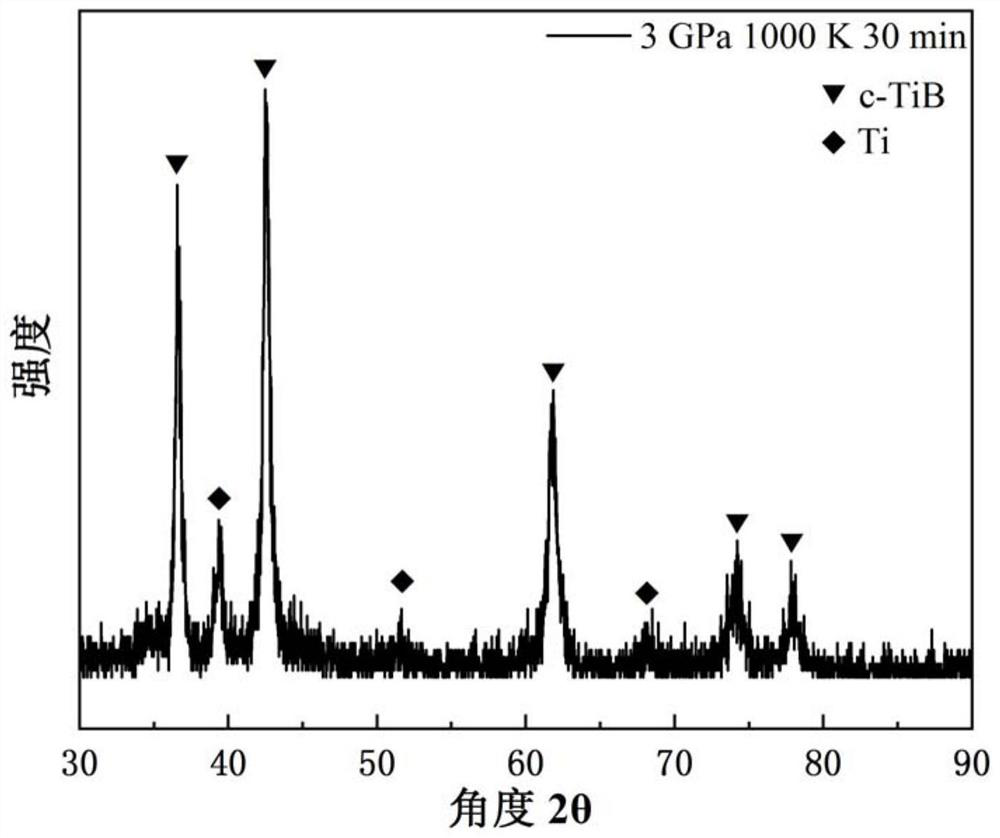

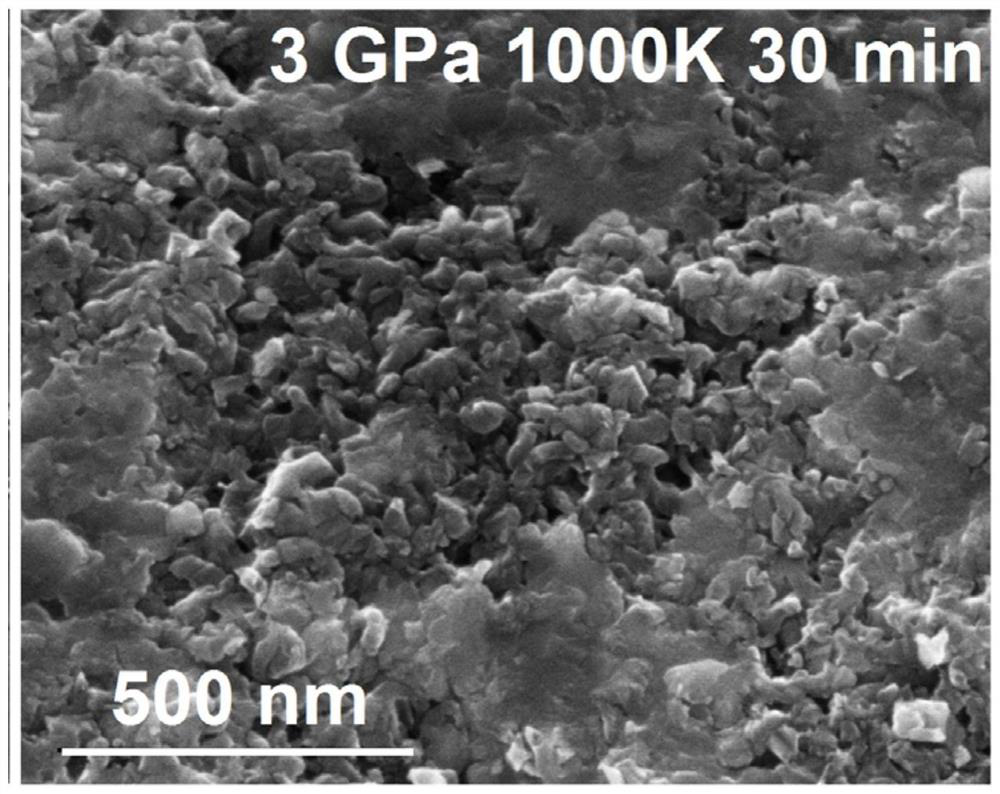

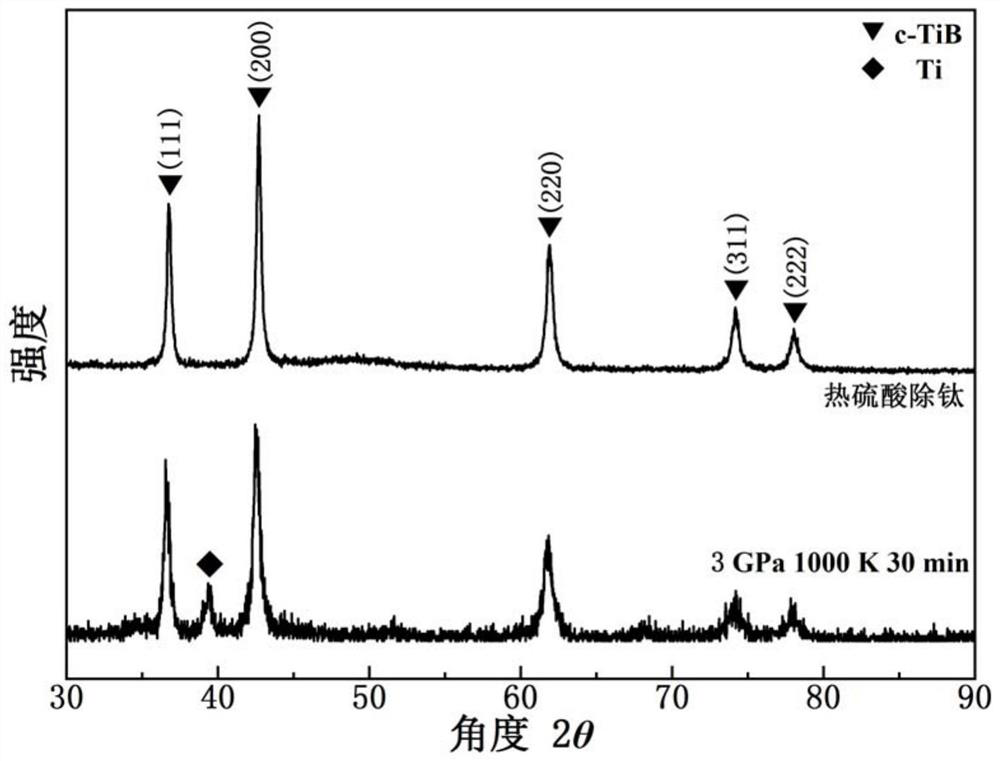

[0027] Adopt the raw material identical with embodiment 1, mol ratio. The synthesis pressure was set to 1, 2, 3, 4, 5 GPa respectively, the synthesis temperature was 1000K, and other conditions and steps were the same as in Example 1. After stopping the heating, the sample is naturally cooled to room temperature and then the pressure is released. The X-ray diffraction results of the obtained sample are shown in Figure 4 , SEM test results see Figure 5 . c-TiB was prepared under these conditions (the remaining small amount of elemental Ti can be removed with hot sulfuric acid). From the SEM image of the sample, it can be found that the samples prepared under the pressure range of 1-5GPa are all nanoparticles, but when the pressure is greater than 3GPa, the samples are dense and difficult to crush.

Embodiment 3

[0029] Using the same raw materials as in Example 1, mixed according to the molar ratio of 1:1, the sample powder was pressed and formed using the same assembly as in Example 1, the synthesis pressure was 3.0GPa, and the synthesis temperature was set to 700K, 850K, and 1000K respectively. The pressure holding time was 30 minutes. After the heating was stopped, the sample was naturally cooled to room temperature and then the pressure was released. The X-ray diffraction results of the obtained sample are shown in Figure 6 . The sample prepared under this condition has already produced c-TiB at 850K, but there is more remaining Ti. With the increase of temperature, the content of c-TiB increases and the content of Ti decreases; at 1000K, the content of Ti is very small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com