An electric filtration catalytic persulfate salt water treatment equipment and a method for using the same to treat water

A technology of water treatment equipment and persulfate, which is applied in water/sewage treatment equipment, special compound water treatment, water/sewage treatment, etc. It can solve the problems of treatment devices and efficiency that need to be improved and improved, so as to improve the efficiency of water treatment , reduce pollution, improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

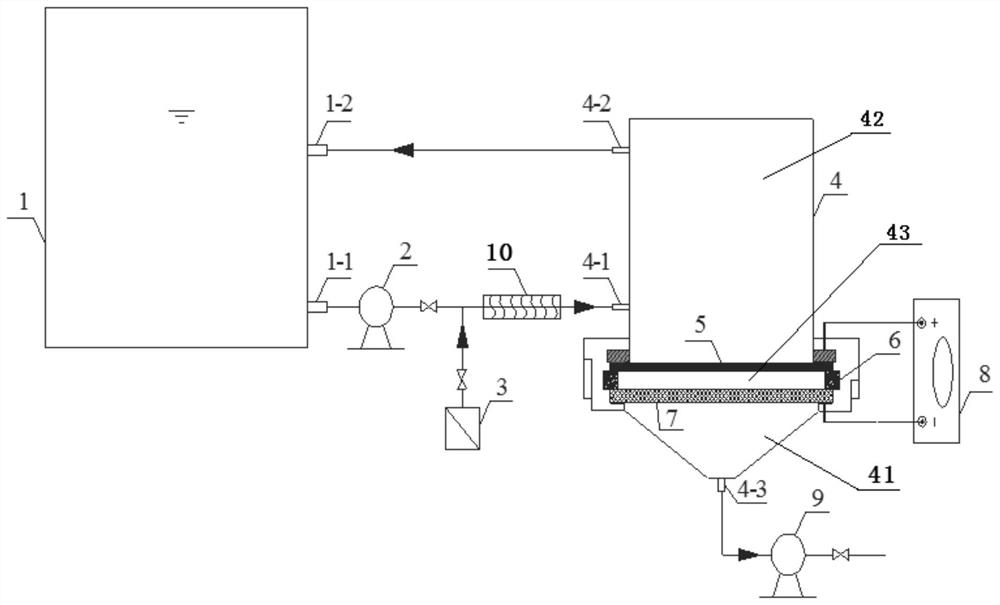

[0038] Equipment for electrofiltration catalyzed persulfate brine treatment, see figure 1 , including a liquid storage device 1, a persulfate dosing device 3 and an electrochemical filter device 4; the electrochemical filter device 4 is internally provided with a parallel anode 5 and a cathode 7 that can breathe through water, and its internal space is divided into The lower chamber 41 below the cathode 7, the upper chamber 42 above the anode 5, and the intermediate chamber 43 between the two electrodes, and the edges of the two electrodes are in a sealed state with the inner wall of the electrochemical filter device 4; liquid storage The device 1 communicates with the upper chamber 42 of the electrochemical filtering device 4 and forms a circulation path, and the persulfate dosing device 3 is connected with the liquid inlet passage of the upper chamber 42; the bottom of the lower chamber 41 of the electrochemical filtering device 4 is provided with Water outlet 4-3.

[0039]...

Embodiment 2

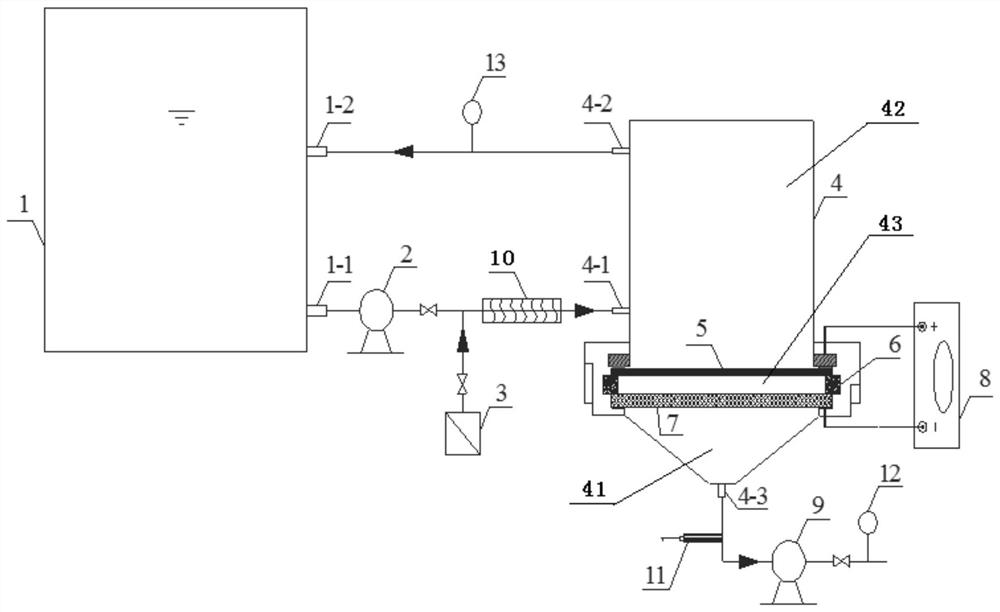

[0049] Equipment for electrofiltration catalyzed persulfate brine treatment, see figure 2 , is basically the same as Embodiment 1, the only difference is that it also includes a pressure sensor 11, a No. 1 liquid flow meter 12 and a No. 2 liquid flow meter 13, and the pressure sensor 11 is placed behind the water outlet 4-3 at the bottom of the lower chamber 41 , before the water inlet of the suction filter pump 9; No. 2 liquid flowmeter 13 is connected to the liquid outlet passage of the upper chamber 42, that is, it is located between the return water outlet 4-2 of the upper chamber and the return water inlet 1-2 of the liquid storage device;

[0050] The pressure sensor 11 is used to monitor the filtration pressure, the No. 1 liquid flow meter 12 is used to monitor the treated water flow, and the No. 2 liquid flow meter 13 is used to monitor the circulation flow.

Embodiment 3

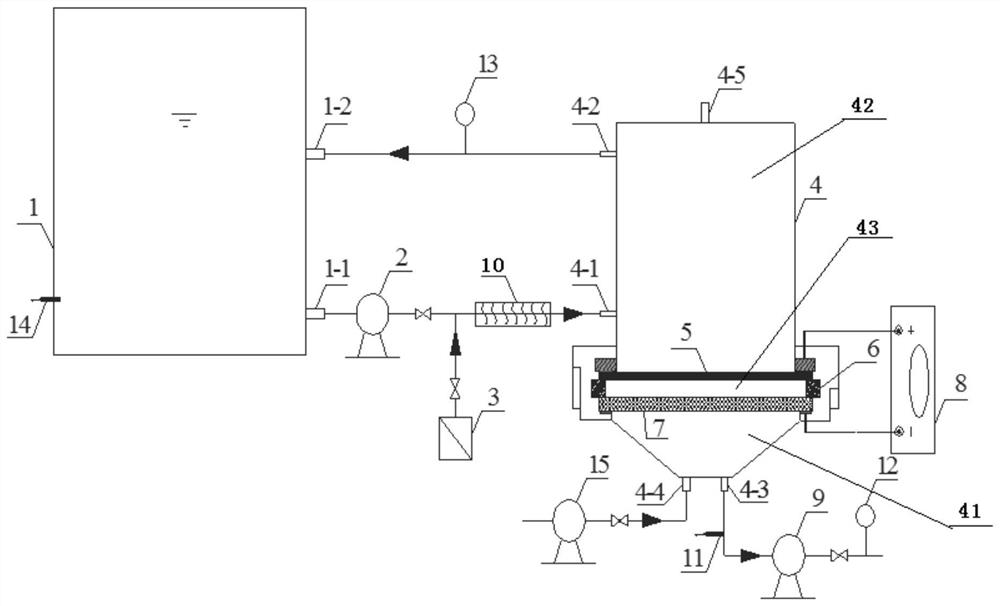

[0052] Equipment for electrofiltration catalyzed persulfate brine treatment, see image 3 , is basically the same as Embodiment 2, the only difference is that it also includes a dissolved oxygen sensor 14, a backwash water inlet 4-4, a backwash water outlet 4-5 and a backwash pump 15. The dissolved oxygen sensor 14 is placed on the side wall of the liquid storage device 1 . The backwash water inlet 4-4 is arranged at the bottom of the lower chamber 41, the backwash water outlet 4-5 is arranged at the top of the upper chamber 42, the water outlet of the backwash pump 15 is connected with the backwash water inlet 4-4, and the backwash pump 15 After the backwash water is pumped into the electrochemical filter device 4, and the membrane electrodes are backwashed, the backwash water is discharged from the backwash outlet 4-5 of the electrochemical filter device 4.

[0053] The specific working principle is as follows:

[0054] When the purified water output becomes smaller and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com