A method of 3D printing magnetic ceramics and magnetic ceramics prepared therefrom

A magnetic ceramic and 3D printing technology, applied in the field of 3D printing ceramics, can solve problems such as magnetic difference, improve anisotropy, reduce R&D cycle and cost, and facilitate industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

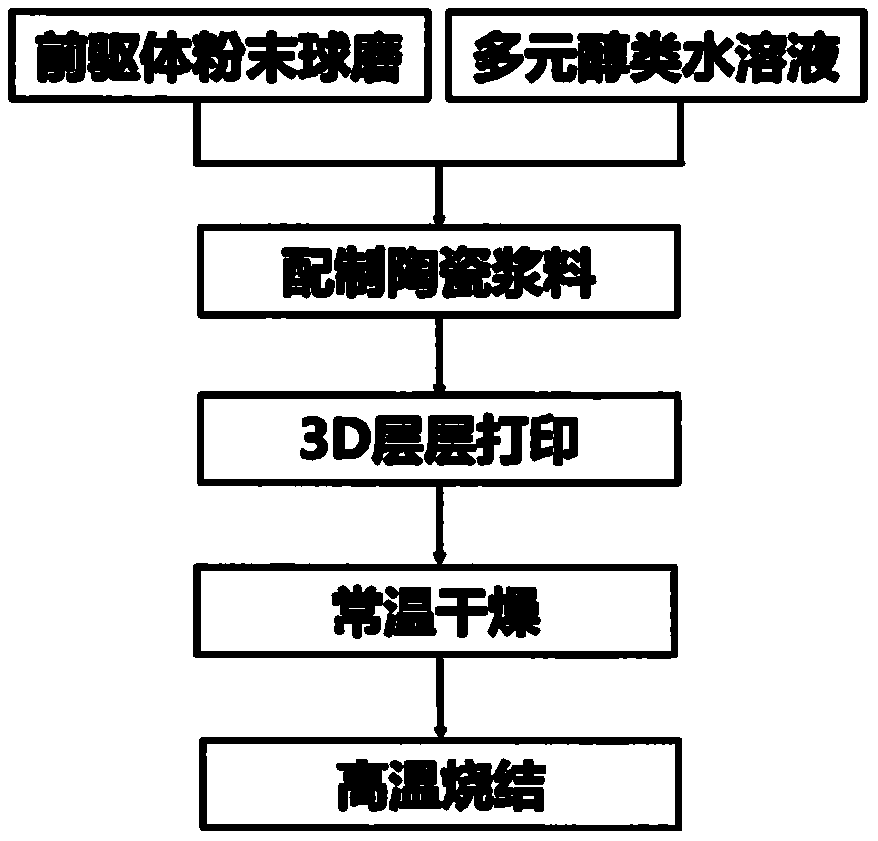

[0037] Such as figure 1 As shown, the 3D printing BaFe described in this embodiment 12 o 19 The method for ceramic materials specifically comprises the steps of:

[0038] (1) Weigh 50g BaFe12 o 19 Precursor powder (BaCO 3 with Fe 2 o 3 The molar ratio of the precursor powder is 1:6), and the precursor powder is put into the zirconia ball milling jar, the mass ratio of the precursor powder and the zirconia ball in the ball milling jar is controlled to be 1:10, the speed of the ball mill is controlled to be 300rpm, and the ball milling time is 4h;

[0039] Disperse the ceramic precursor particles obtained after ball milling in polyvinyl alcohol aqueous solution (12.0wt%), stir evenly, and contain polyethylene glycol (8.0wt%) and a small amount of lauryl ether (0.8wt%) in the aqueous solution at the same time , controlling the volume content of the ceramic precursor particles in the polyvinyl alcohol aqueous solution to be 35vol%, to obtain a ceramic slurry;

[0040] (2) ...

Embodiment 2

[0044] The method for 3D printing ceramic materials described in this embodiment is the same as in Example 1, the only difference being that the ceramic powder used is SrCO 3 and Fe 2 o 3 (molar ratio is 1:6), for the preparation of SrFe 12 o 19 Ceramic material.

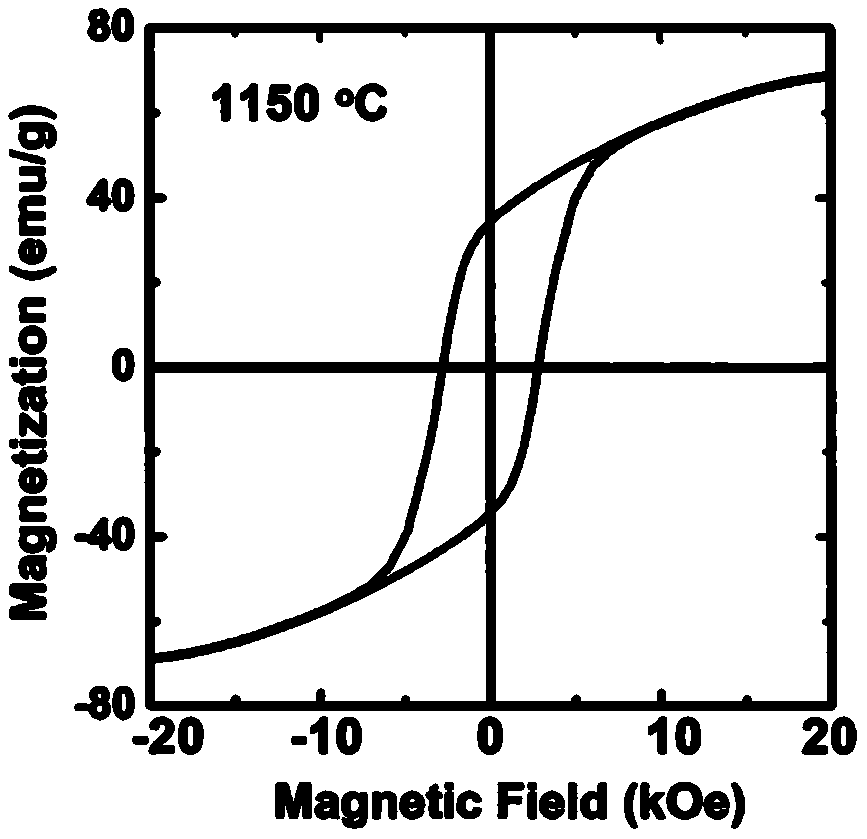

[0045] After measurement, the coercive force H of the magnetic ceramic material obtained in this embodiment c It can reach 4.85kOe, and the sintered density can reach 4.64g / cm 3 , after calculating the maximum magnetic energy product density (BH) max Reaching 2.51MGOe, the magnetic properties are superior.

Embodiment 3

[0047] Such as figure 1 As shown, the 3D printing BaFe described in this embodiment 12 o 19 The method for ceramic materials specifically comprises the steps of:

[0048] (1) Weigh 50g BaFe 12 o 19 Precursor powder (BaCO 3 with Fe 2 o 3 The molar ratio of the precursor powder is 1:6), and the precursor powder is put into the zirconia ball mill jar, the mass ratio of the precursor powder and the zirconia ball in the ball mill jar is controlled to be 1:5, the speed of the ball mill is controlled to 400rpm, and the milling time is 10h;

[0049] The ceramic precursor particle that obtains after ball milling is dispersed in the methyl cellulose aqueous solution (10.0wt%), stirs evenly, contains polyethylene glycol (6.0wt%) and a small amount of dodecyl ether (1.0wt%) simultaneously in the aqueous solution ), controlling the volume content of the ceramic precursor particles in the polyvinyl alcohol aqueous solution to be 25vol%, to obtain a ceramic slurry;

[0050] (2) Tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com