Soil alkali fusion pretreatment method

An alkaline melting and soil technology, applied in the field of analytical chemistry, can solve the problems of inability to detect and high risk, and achieve the effect of improving efficiency, increasing the number of samples, and expanding the scope of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

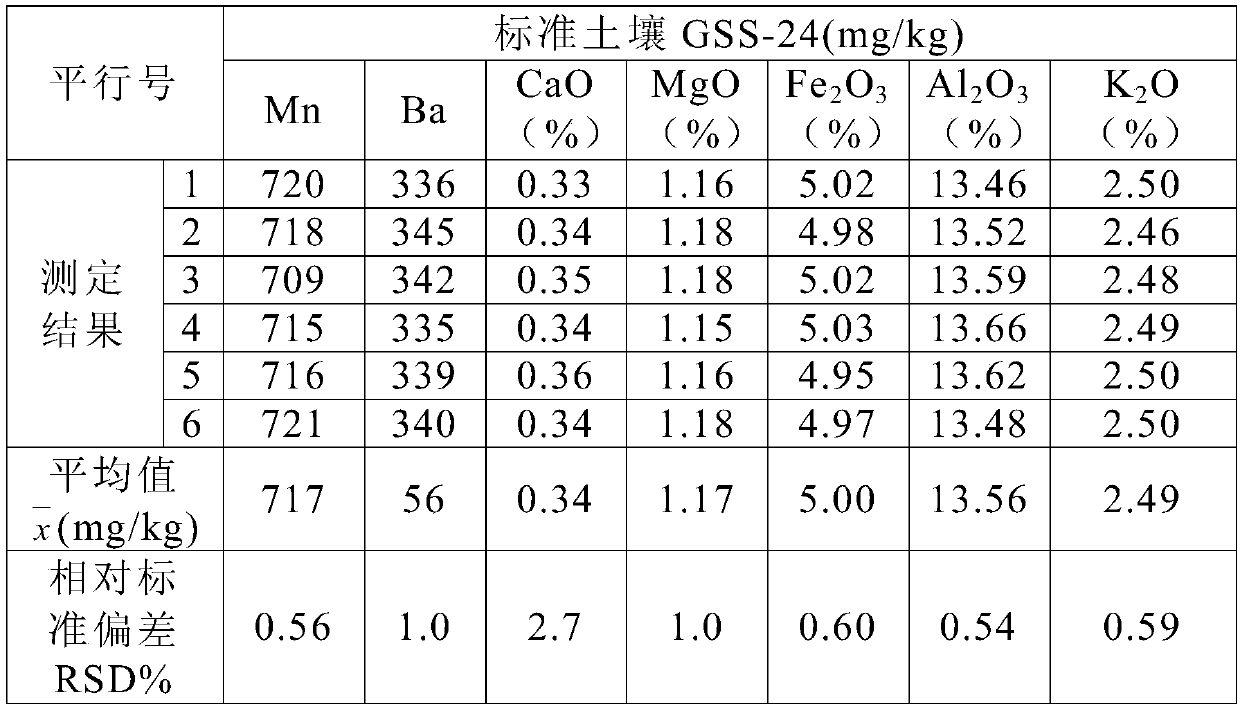

Embodiment 1

[0060] (1) Sample treatment: Air-dry, grind, and mix the four samples of standard soil GBW07405 (GSS-5), standard soil GBW07453 (GSS-24), standard sediment GBW07311 (GSD-11), and actual soil, respectively. Sieve and measure the moisture content respectively;

[0061] (2) Digestion: Weigh 0.5g of 4 kinds of samples with known moisture content and place them in corundum crucibles respectively, place the crucibles on the alkali fusion weighing device respectively, first weigh 1.0g of sodium carbonate and place them at the bottom of the crucible, then Add 0.1g of lithium tetraborate and 0.4g of lithium metaborate, transfer the crucibles one by one to the heating box of the temperature-adjustable heating and digestion device with the mechanical arm, heat at 1000°C for 30min, and cool to 300°C to obtain 4 kinds of digestion samples ;

[0062] (4) Post-processing: transfer the 4 kinds of digestion samples to the alkali fusion weighing device one by one by using the mechanical arm, a...

Embodiment 2

[0075] (1) Sample treatment: Air-dry, grind, and mix the four samples of standard soil GBW07405 (GSS-5), standard soil GBW07453 (GSS-24), standard sediment GBW07312 (GSD-12), and actual soil, respectively. Sieve and measure the moisture content respectively;

[0076] (2) Pre-digestion: Weigh 0.5g of 4 kinds of samples with known moisture content and place them in corundum crucibles, place the crucibles on the alkali fusion weighing device, add 10ml of hydrofluoric acid dropwise to the crucibles, and use the mechanical arm to Transfer the crucibles one by one to the heating box of the temperature-adjustable heating and digestion device, heat at 100°C for 20 minutes, and cool for 20 minutes to room temperature to obtain the pre-digestion sample;

[0077] (3) Re-digestion: transfer the pre-digested samples to the alkali fusion weighing device respectively, add 5 g of sodium peroxide to the crucible, and then transfer the crucibles one by one to the heating box of the temperature-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com