Preparation method of surface cationic polystyrene microsphere

A technology of polystyrene microspheres and cations, applied in the field of materials, can solve the problems of polystyrene microspheres containing positively charged quaternary ammonium groups, wide particle size distribution range, single surface function, etc., to achieve good monodispersity, particle size The effect of narrow diameter distribution and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

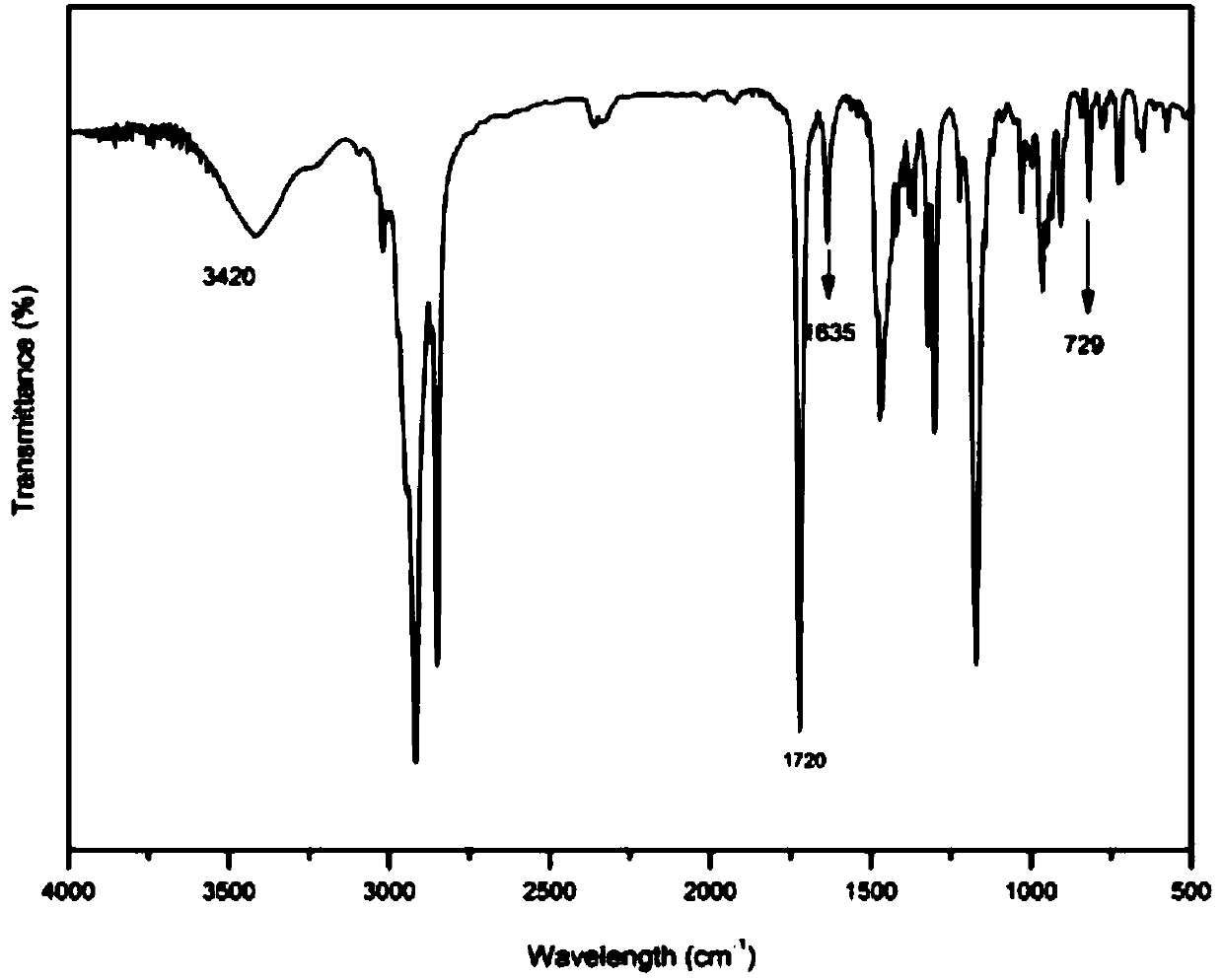

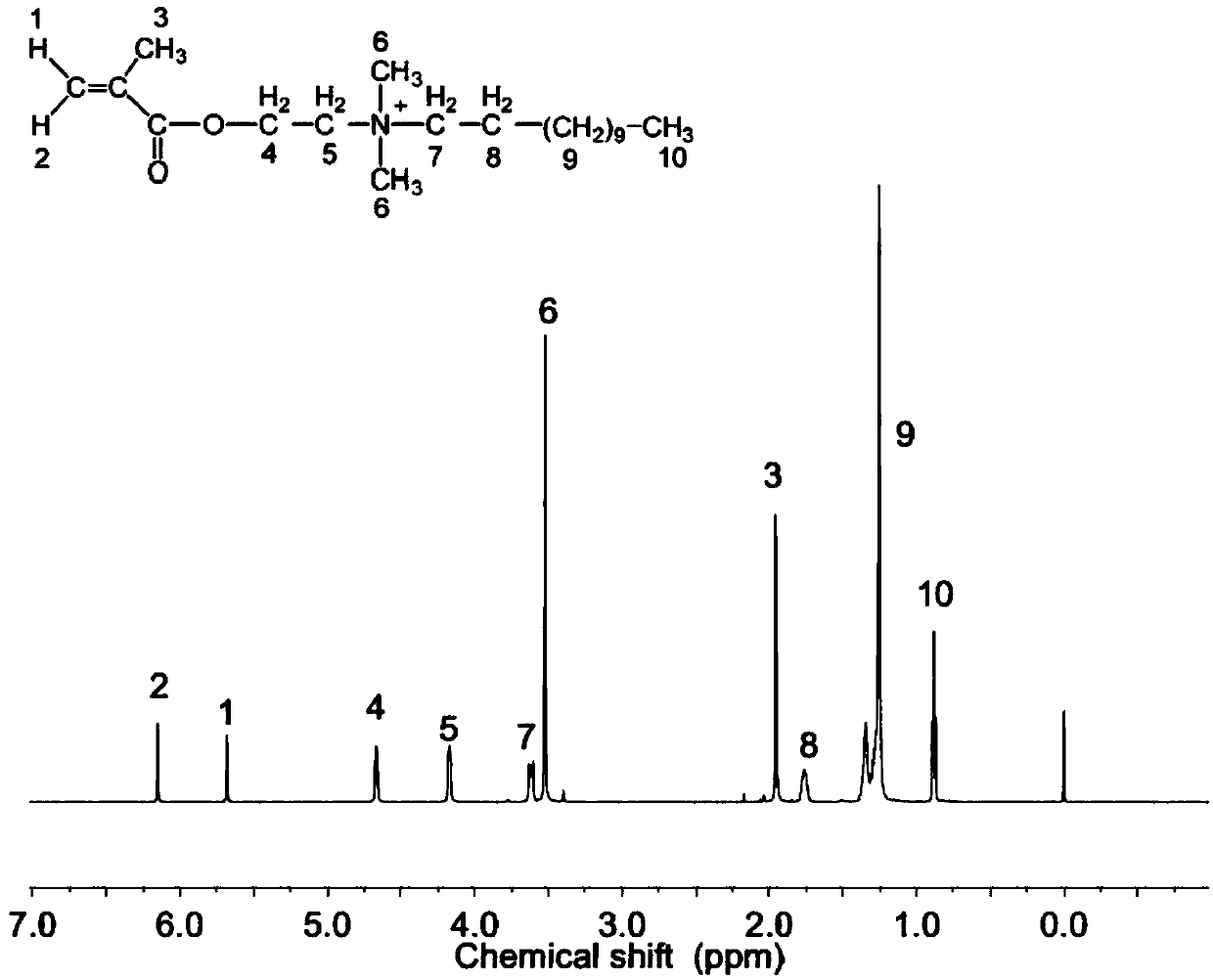

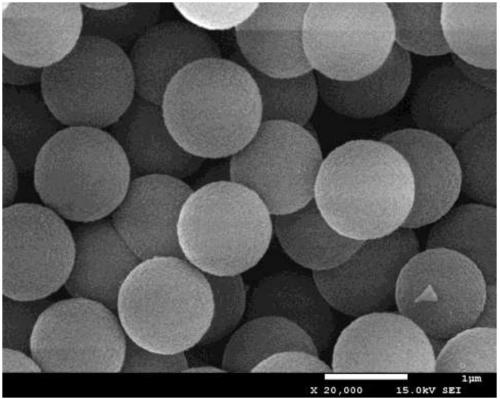

[0048] The present embodiment provides a kind of preparation method of preparing cationic polystyrene microsphere, comprises the AEO-9 of 2.0g PVPK30 (being the polyvinylpyrrolidone of K value 30) and 0.40g, 80g ethanol and 20g water are added to In a 250ml four-neck flask equipped with a condenser tube, a thermometer, stirring and a nitrogen tube, adjust the appropriate stirring speed, heat up the water bath to 60°C, and dissolve azobisisobutyronitrile with a monomer mass ratio of 1.5% in 10g of styrene monomer In, the polymerization reaction occurs;

[0049] After two hours of polymerization, use a balance funnel to slowly add 10 mL of an ethanol aqueous solution of methacryloyloxydodecyldimethylammonium bromide with a concentration of 0.201 mol / L. The dropping time is controlled at 20-30 minutes, and the constant temperature is continued. Polymerization 10h;

[0050]After the reaction, the reaction system was cooled to room temperature, the microspheres were fully washed w...

Embodiment 2

[0052] This embodiment provides a kind of preparation method of preparing cationic polystyrene microspheres, the AEO-9 of the PVPK30 of 2.0g and 0.40g, 80g ethanol and 20g water are added to condenser pipe, thermometer, stirring and nitrogen pipe are housed In a 250ml four-neck flask, adjust the appropriate stirring speed, raise the temperature of the water bath to 61°C, dissolve azobisisobutyronitrile with a monomer mass ratio of 1.5% in 10g of styrene monomer, and polymerize;

[0053] After two hours of polymerization, use a balance funnel to slowly add 10 mL of an ethanol aqueous solution of methacryloyloxydodecyldimethylammonium bromide with a concentration of 0.402 mol / L, and the dropping time is controlled at 20-30 minutes. Polymerization at 60°C for 10h;

[0054] After the reaction, the reaction system was cooled to room temperature, the microspheres were fully washed with 95% ethanol and suction filtered to remove the dispersant on the surface, and dried to constant we...

Embodiment 3

[0056] This embodiment provides a kind of preparation method of preparing cationic polystyrene microspheres, the AEO-9 of the PVPK30 of 2.0g and 0.40g, 80g ethanol and 20g water are added to condenser pipe, thermometer, stirring and nitrogen pipe are housed In a 250ml four-neck flask, adjust the appropriate stirring speed, raise the temperature of the water bath to 59°C, dissolve the initiator azobisisobutyronitrile with a monomer mass ratio of 1.5% in 10g of styrene monomer, and polymerize;

[0057] After two hours of polymerization, use a balance funnel to slowly add 10ml of an ethanol aqueous solution of methacryloyloxydodecyldimethylammonium bromide with a concentration of 0.603mol / L, and the dropping time is controlled at 20-30min. Polymerization at ℃ for 10h;

[0058] After the reaction, the reaction system was cooled to room temperature, the microspheres were fully washed with 95% ethanol and suction filtered to remove the dispersant on the surface, and dried to constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| critical micelle concentration (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com