High-temperature anti-ablative coating formed on base material as well as preparation method and application of high-temperature anti-ablative coating

A base material and anti-ablation technology, applied in the field of high-temperature thermal protection coating and preparation, can solve the problems of inability to prepare structure, good performance, low porosity, etc., and achieve excellent high-temperature ablation resistance, low porosity, High bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

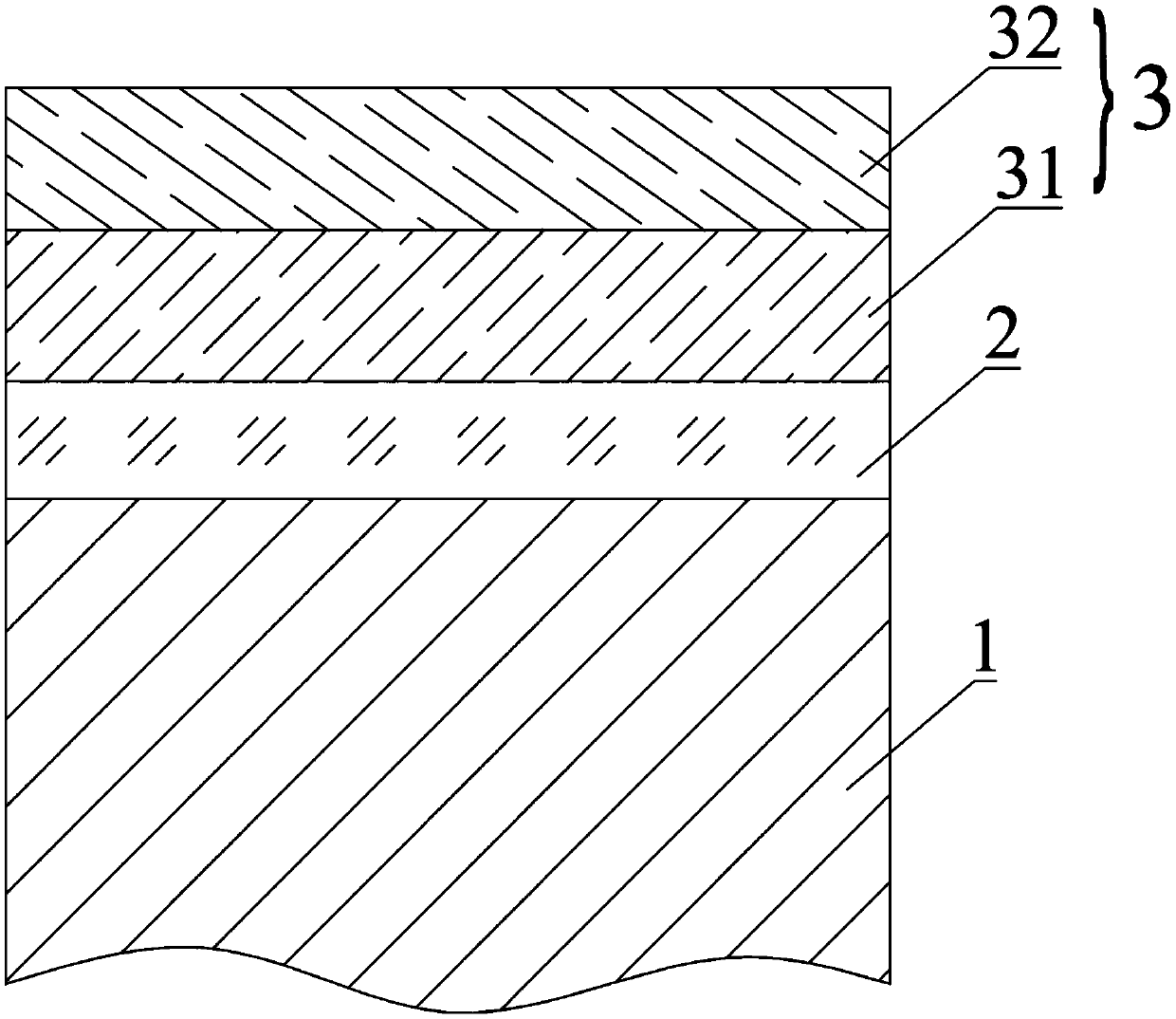

[0042] In a second aspect, the present invention provides a method for preparing the high-temperature anti-ablation coating described in the first aspect of the present invention, said method comprising the steps of:

[0043] (1) Depositing the SiC transition layer on the surface of the base material by chemical vapor deposition (CVD for short);

[0044] (2) prepare said ZrC-SiC-Gd on the described SiC transition layer of base material by vacuum plasma spraying method (abbreviation VPS method) 2 o 3 A multi-phase oxygen barrier layer, whereby the high-temperature ablation-resistant coating is prepared on the base material.

[0045] According to some preferred embodiments, the step (2) includes the following sub-steps:

[0046] (a) Gd 2 o 3 Powder and ZrC powder and SiC powder with a molar ratio of (0.8-1.2):1 are mixed evenly to obtain the first mixed powder, and the Gd 2 o 3 Powder and ZrC powder and SiC powder with a molar ratio of (3-5): 1 are uniformly mixed to obtai...

Embodiment 1

[0072] S1. Prepare C. f / C-SiC ceramic matrix composite matrix original piece, the size is Φ30×10mm, respectively with 400 # , 800 # , 1200 # Polish the surface with sandpaper, put it in an acetone solution for ultrasonic cleaning for 10 minutes, and set it aside.

[0073] S2, the C f / C-SiC composite material is placed in a high-temperature furnace, heated to 1050 ° C, using trichloromethylsilane vapor as the SiC raw material, and the deposition time is 20 h. After the temperature in the furnace drops to room temperature, the sample is taken out, and the f A SiC transition layer with a thickness of 40 μm was obtained on the surface of the / C-SiC composite.

[0074] S3. Select ZrC-SiC-Gd produced after spray granulation 2 o 3 Hollow spherical micron powder A (the molar ratio of ZrC to SiC is 1:1) and ZrC-SiC-Gd 2 o 3 Hollow spherical micron powder B (the molar ratio of ZrC to SiC is 4:1), Gd 2 o 3 The doping amount in the hollow spherical micron powder A and the holl...

Embodiment 2

[0082] Embodiment 2 is basically the same as Embodiment 1, the difference is:

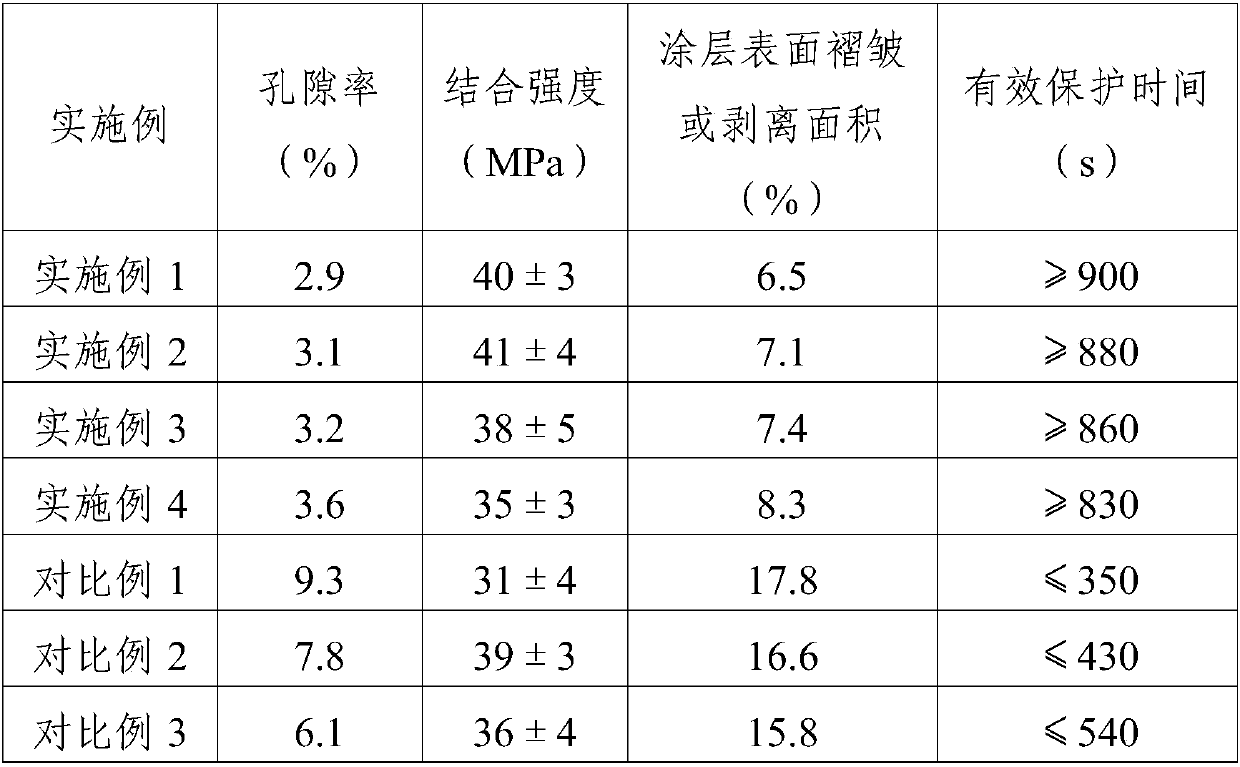

[0083] In S3, Gd 2 o 3 The doping amount in hollow spherical micron powder A and hollow spherical micron powder B is constant, and the mole percentage is 10%.

[0084] The SiC / ZrC-SiC-Gd prepared in this example was tested by the same test method as in Example 1. 2 o 3 The porosity, bonding strength and high-temperature ablation resistance of the multiphase coating have been tested, and the test results are shown in Table 1; in the present embodiment, the C f / C-SiC ceramic matrix composites were subjected to high-temperature ablation resistance tests. During the ablation process, the surface temperature of the material was 2100°C, and the ablation time was 880s. After ablation, the structure of the material was complete. SiC / ZrC-SiC- Gd 2 o 3 The multiphase coating can effectively protect the ceramic matrix composite for at least 880s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com