Diamond sheet grinding wheel

A diamond and flake technology, applied in the formulation and preparation of diamond flake grinding wheel materials, can solve the problems of short service life and low cutting efficiency, and achieve the effects of long service life, weak grinding effect and good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of diamond sheet grinding wheel of the present invention, step is as follows:

[0016] (1) Weighing: Use FA / JA series electronic balance to weigh the resin-bonded diamond flakes one by one, turn on the power to preheat for 30 minutes; then place a clean and dry small beaker on the balance, Press the tare button after the balance display is stable, wait for the balance display to be zero or close to zero, then put the ingredients to be weighed into the beaker and weigh them one by one;

[0017] (2) Mixing: mixing is the process of fully mixing and uniforming resin bond, diamond abrasive, filler and external ingredients. Spread the material; the specific method is as follows: a. Add the wetting agent cresol to the diamond abrasive and mix evenly; b. Mix the filler materials copper powder, zinc oxide, chromium oxide, SiC micropowder, and ferric oxide evenly and carry out Sieve operation; c. Mix the resin binder phenolic resin and the mixed filler ev...

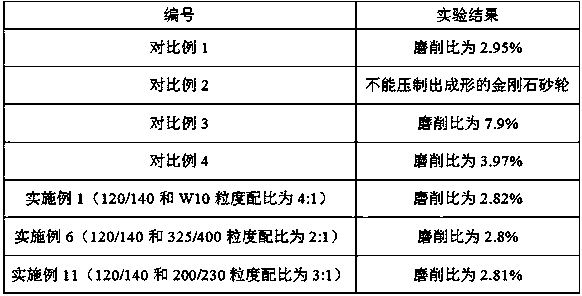

Embodiment 1

[0027] The diamond flake grinding wheel of the present embodiment, the volume ratio is composed as follows: 25% of diamond abrasives, 45% of resin bond, 10% of copper powder, 4% of zinc oxide, 6% of chromium oxide, 10% of SiC micropowder and cresol; The diamond abrasive is compounded by 120 / 140 and W10 in a mass ratio of 4:1.

Embodiment 2-5

[0029] The diamond abrasive in this embodiment is compounded by 120 / 140 and W10 in mass ratios of 5:1, 2:1, 3:1, and 1:1, and the rest of the formulations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com