Simulation assembly type prefabricated wall grouting process test system

A prefabricated wall and process test technology, applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of timely detection and troubleshooting of grouting sleeve connection quality defects, and achieve the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

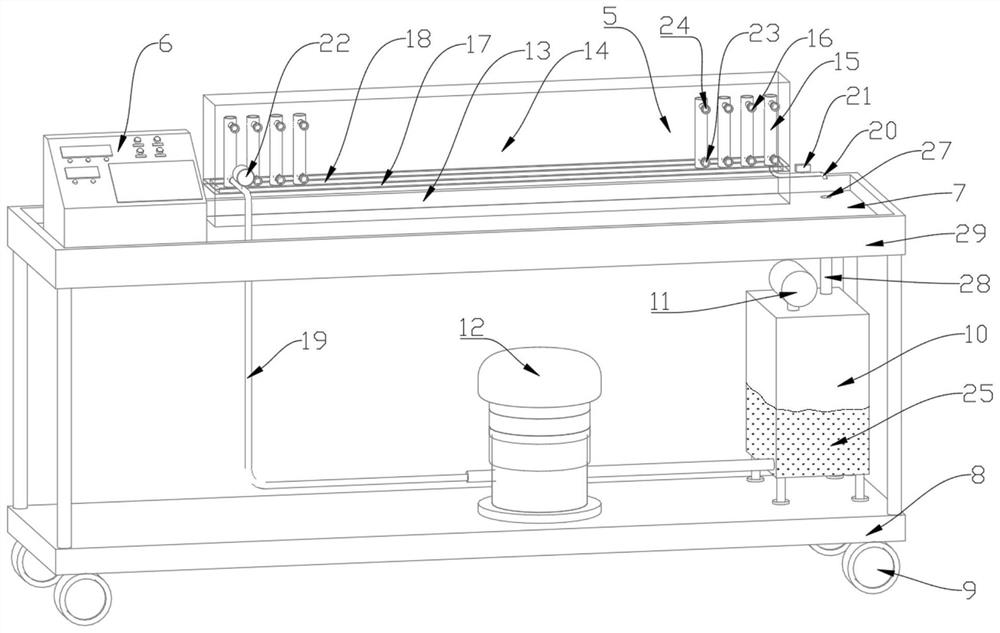

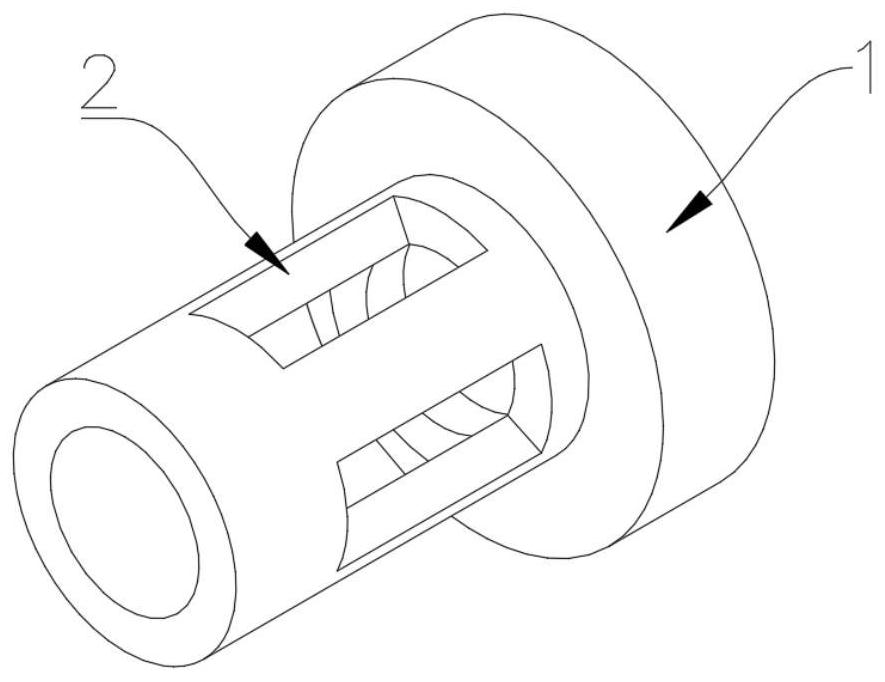

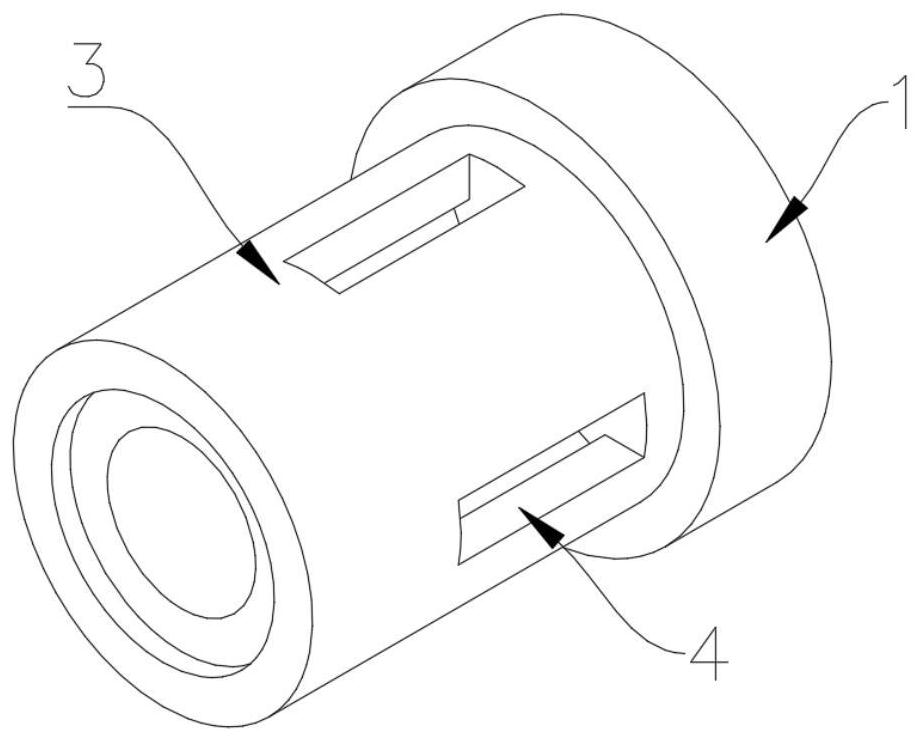

[0022] The present invention provides a kind of simulated prefabricated wall grouting process test system, this system includes mobile demonstration platform, demonstration device and console 6, wherein said demonstration device and console 6 are installed on the mobile demonstration platform, demonstration device Including a simulated prefabricated wall assembly 5 and a grouting system, the simulated prefabricated wall assembly 5 is connected with the grouting system through a pipeline to realize the simulation of the grouting process and the recovery of the slurry 25, the size of the simulated prefabricated wall assembly 5 The size of the spacing is modeled on the actual working conditions on si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com