A kind of turning processing method of silicon carbide whisker reinforced aluminum matrix composite material

A technology of silicon carbide whiskers and reinforced aluminum base is applied in the field of composite material turning processing, which can solve the problems that the surface roughness of the workpiece has a great influence, the service performance of the components has a great influence, and the tool wear is relatively serious, so as to reduce the machined surface. The effect of roughness, reducing residual stress in cutting, and improving service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] Preparation of SiC-reinforced aluminum-matrix composite rods: SiCw / Al aluminum-matrix composites were manufactured by extrusion casting, and the reinforcement was TWS-100β-SiC whiskers produced by Tokai Carbon Co., Ltd., Japan. The whisker volume fraction was 15-30%, the matrix is pure aluminum, 2024, 6061, 7075 and other aluminum alloys. The as-cast SiCw / Al composite material is hot-extruded at 500°C, and the extrusion ratio is greater than 12:1 to obtain a hot-extruded rod, and the whiskers are oriented along the direction of the rod axis.

[0015] The SiCw / Al aluminum-based composite material with a volume fraction of whiskers of 20% is used for the examples that the whiskers are chaotically distributed, the whiskers are perpendicular to the axis of the rod to be processed, and the whiskers are parallel to the axis of the rod to be processed. .

Embodiment

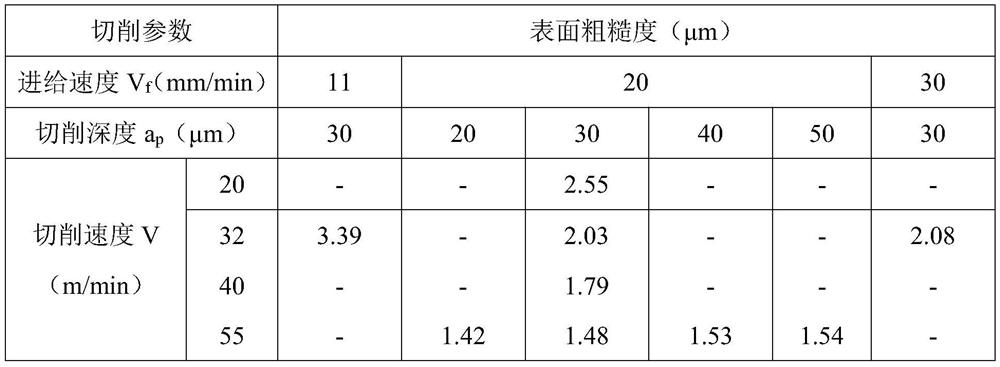

[0017] High-precision turning of silicon carbide whisker-reinforced aluminum matrix composites according to the following parameters:

[0018] Tool selection: use single crystal diamond turning tool or polycrystalline diamond blade, tool rake angle γ0=0-5°, back angle α0=5-8°, main declination angle Kr=45-75°, secondary declination angle Kr'= 10-15°, the blade inclination angle λs=0°, the radius of the arc of the tool nose r=0.3-0.5mm. Before turning, the diamond inserts are assembled on matching toolholders.

[0019] Select coolant: add kerosene as lubrication and coolant to reduce the formation of scales and reduce the roughness of the machined surface.

[0020] The outer surface of SiCw / Al composite bar is processed by numerical control lathe. Feed speed Vf=5-40mm / min, cutting depth ap=10-50μm, cutting speed V=10-60m / min.

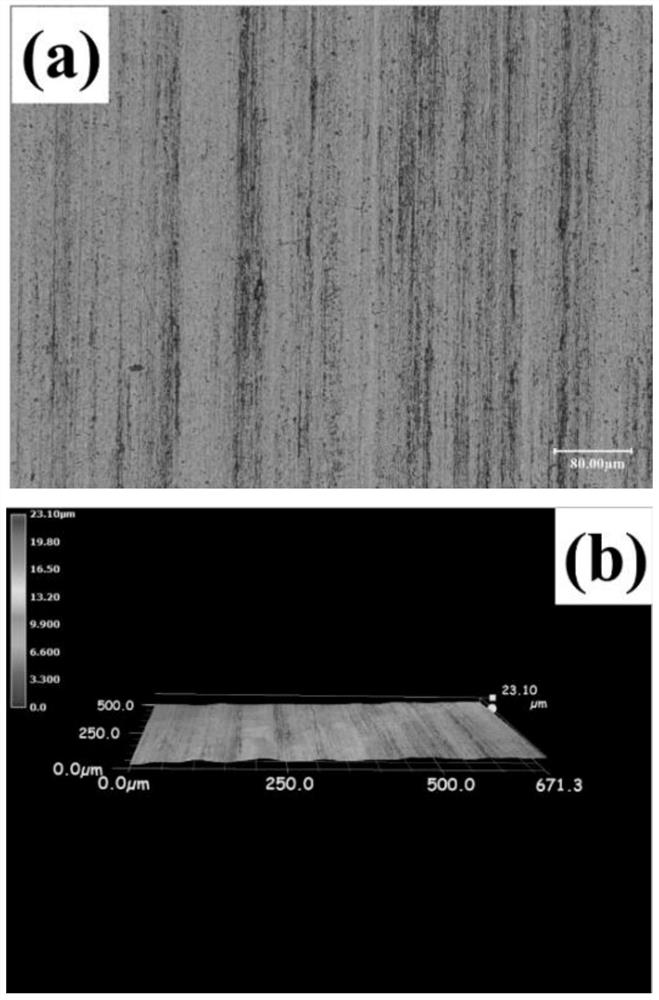

[0021] figure 1 is a schematic diagram of the turning process of SiCw / Al composites with three different whisker orientations, where the volume frac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com