Supported cobalt-nitrogen doped carbon catalyst as well as preparation method and application thereof

A nitrogen-doped carbon and catalyst technology, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of high preparation cost, complicated process, and serious environmental pollution, and achieve low preparation cost and catalyst The effect of simple process and high catalyst yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

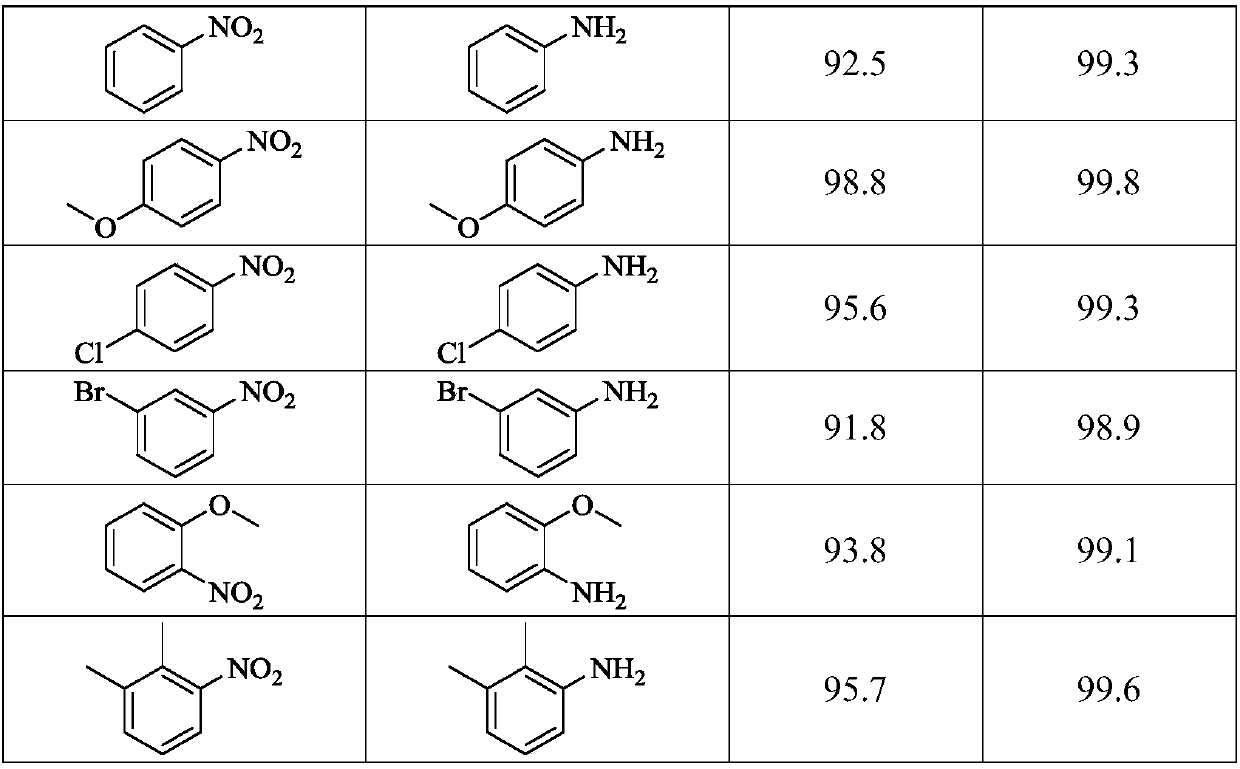

Examples

Embodiment 1

[0028] Add 0.1g cobalt phthalocyanine, 10g Ce-Al 2 o 3 , 0.04g of urea, and then placed in a ball mill for full ball milling for 2h, the resulting mixture was placed in a nitrogen atmosphere furnace, roasted at 600°C for 10h, cooled naturally to room temperature and taken out to obtain the supported cobalt-nitrogen doped Carbon catalyst, denoted as C1.

[0029] In a stainless steel autoclave with mechanical stirring, electric heating, thermocouple and pressure display, respectively add nitrobenzene, tetrahydrofuran (10 times the mass of nitrobenzene), and catalyst C1, wherein the molar amount of catalyst (calculated as Co) is 1% of nitrobenzene. After the feeding is completed, cover the lid of the kettle, start stirring, control the stirring speed to 600r / min, stir until the mixture is uniform, connect hydrogen, adjust the hydrogen pressure to 2MPa, raise the temperature to 110°C to start the reaction, and keep the hydrogen pressure constant during the reaction . After rea...

Embodiment 2

[0031] Add 1.4g of cobalt phthalocyanine, 10g of carbon powder, and 0.44g of 1,10-phenanthroline into a ball mill jar equipped with zirconium beads, and then place them in a ball mill for full ball milling for 0.5h, and then place the resulting mixture in a nitrogen atmosphere furnace , calcined at 900° C. for 8 h, cooled down to room temperature naturally, and then taken out to obtain the supported cobalt-nitrogen-doped carbon catalyst, denoted as C2.

[0032] In a stainless steel autoclave with mechanical stirring, electric heating, thermocouple and pressure display, add nitrobenzene, tetrahydrofuran (10 times the quality of nitrobenzene), and catalyst C2 respectively, wherein the molar amount of catalyst (calculated as Co) is 2% of nitrobenzene. After the feeding is completed, cover the lid of the kettle, start stirring, control the stirring speed to 600r / min, stir until the mixture is uniform, connect hydrogen, adjust the hydrogen pressure to 3MPa, raise the temperature to...

Embodiment 3

[0034] Add 0.6g cobalt phthalocyanine, 10g Ce-Al 2 o 3 , 0.53g of dicyandiamide, and then placed in a ball mill for full ball milling for 5 hours, and then the resulting mixture was placed in a nitrogen atmosphere furnace, roasted at 400°C for 3 hours, cooled naturally to room temperature, and then taken out to obtain the supported cobalt - Nitrogen-doped carbon catalyst, denoted C3.

[0035] In a stainless steel autoclave with mechanical stirring, electric heating, thermocouple and pressure display, add nitrobenzene, tetrahydrofuran (10 times the quality of nitrobenzene), and catalyst C3 respectively, wherein the molar amount of catalyst (calculated as Co) is 3% of nitrobenzene. After the feeding is completed, cover the lid of the kettle, start stirring, control the stirring speed to 600r / min, stir until the mixture is uniform, connect hydrogen, adjust the hydrogen pressure to 4MPa, raise the temperature to 100°C to start the reaction, and keep the hydrogen pressure constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com