Hydrogel composite material with near-infrared response temperature sensitive characteristic and method for preparing hydrogel composite material

A technology of sensitive properties and composite materials, which is applied in the field of hydrogel composite materials and its preparation, can solve the problems of low mechanical strength and achieve the effects of improving mechanical strength, excellent repeatability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

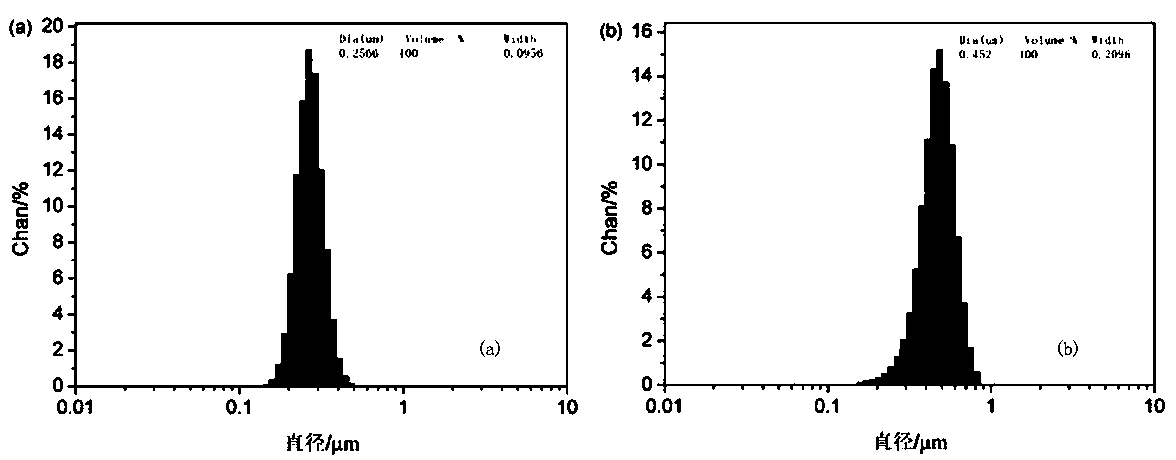

[0035]A hydrogel composite with temperature-sensitive properties of near-infrared response, made from the following raw materials by weight: 2-methyl-2-acrylate-2(2-methoxyethoxy)ethyl ester (MOE2MA) 3.0 g (0.016mol), 1.0 g of cellulose nanocrystal suspension (the quality of cellulose nanocrystal is 0.66% of the mass of polymerized monomer), 9.0 g of polydopamine nanoparticle suspension (the quality of PDA in the suspension is the mass of polymerized monomer 0.45% of ), 2.0 mg N,N-methylenebisacrylamide (crosslinker) and 20 mg ammonium persulfate (initiator), 10 mg N,N',N',N'-tetramethyldiethyl Amine (TEMD) made.

[0036] The cellulose nanocrystals are obtained from microcrystalline cellulose through strong acid hydrolysis, dialysis and purification, and exist in the state of an aqueous suspension. The diameter of the cellulose nanocrystals in the cellulose nanocrystal suspension is 10-30 nm, and the length is 100-100 nm. 400nm, the mass concentration is 2%.

[0037] The pre...

Embodiment 2

[0046] A hydrogel composite with near-infrared-responsive temperature-sensitive properties made from the following raw materials by weight: 2-methyl-2-acrylate-2(2-methoxyethoxy)ethyl ester (MOE 2 MA) 2.5g (0.013mol), 2.5g cellulose nanocrystal suspension (the mass of cellulose nanocrystal is 2.0% of the mass of polymerized monomer), 8.0 g polydopamine nanoparticle suspension (the mass of PDA in the suspension is 0.40% of the mass of polymerized monomers), 2.5 mg ethylene glycol dimethacrylate (crosslinker) and 20 mg ammonium persulfate (initiator), 10 mg N,N',N',N'-tetramethyl Diethylamine (TEMD) made.

[0047] The cellulose nanocrystals are obtained from microcrystalline cellulose through strong acid hydrolysis, dialysis and purification, and exist in the state of an aqueous suspension. The diameter of the cellulose nanocrystals in the cellulose nanocrystal suspension is 10-30 nm, and the length is 100-100 nm. 400nm, the mass concentration is 2%.

[0048] The preparation m...

Embodiment 3

[0057] A hydrogel composite with near-infrared-responsive temperature-sensitivity properties prepared from the following raw materials by weight: 2.5 g (0.013 mmol) 2-methyl-2-acrylic acid-2(2-methoxyethoxy)ethyl Esters (MOE 2 MA), 0.9g (0.003 mol) oligoethylene glycol methyl ether methyl methacrylate (Mw=300g / mol), 1.0g cellulose nanofiber suspension (the mass of cellulose nanofiber is the mass of polymerized monomer 0.88%), 9.0 g polydopamine nanoparticle suspension (the mass of PDA in the suspension is 0.40% of the mass of M polymerized monomer), 2.5 mg ethylene glycol dimethacrylate (cross-linking agent) and 20 mg persulfuric acid ammonium (initiator), 10 mg N,N',N',N'-tetramethyldiethylamine (TEMD).

[0058] The cellulose nanofibers are obtained from wood pulp after undergoing TEMPO oxidation reaction, mechanical grinding and high-pressure homogenization, and exist in the state of an aqueous suspension. The diameter of the cellulose nanofibers in the cellulose nanofiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com