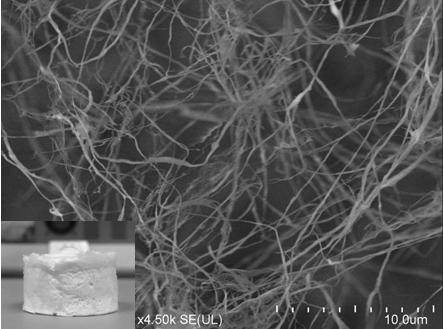

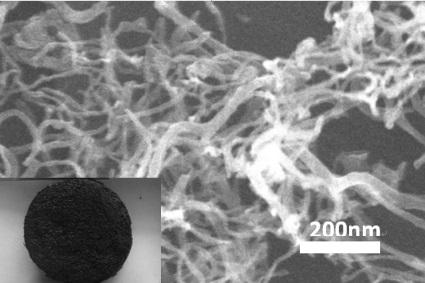

Method for preparing carbon nanofiber aerogel from plant fiber

A carbon nanofiber and plant fiber technology, applied in the field of nanomaterials, can solve the problems of unfavorable carbon nanofiber airgel industrialization process, high preparation cost, toxic reagents, etc., and achieve simple and easy preparation process, short preparation time, solvent little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Repeatedly wash a certain amount of bagasse with deionized water for 3 times, put it in an oven at 80°C, and dry it for 12 hours; crush the dried bagasse by a pulverizer, and pass through a 80-mesh sieve to obtain bagasse powder;

[0034] (2) Take 10g of 80-mesh bagasse powder and disperse it in 100ml of sodium hydroxide solution with a mass concentration of 10%, pour the mixture into a 250ml Teflon sealed tank, and put it in an oil bath at 100°C. After magnetic stirring for 1h, cool naturally; then the cooled mixed solution is suction filtered and washed 3 times to obtain bagasse pulp; then the bagasse pulp is put into a 250ml Erlenmeyer flask, and 20ml of mass concentration is added to bleach with hydrogen peroxide of 30%. to 70°C, magnetically stirred for 2 hours, cooled naturally, filtered and washed 3 times, put the bagasse obtained by suction filtration into an Erlenmeyer flask, added 100ml of sodium hydroxide solution with a mass concentration of 5%, heated in...

Embodiment 2

[0041](1) Repeatedly wash a certain amount of bagasse with deionized water for 3 times, put it in an oven at 100°C, and dry it for 10 hours; crush the dried bagasse by a pulverizer, and pass through a 80-mesh sieve to obtain bagasse powder;

[0042] (2) Take 10g of 80-mesh bagasse powder and disperse it in 100ml of sodium hydroxide solution with a mass concentration of 12%, pour the mixture into a 250ml Teflon sealed tank, and put it in an oil bath at 95°C. After magnetic stirring for 2h, cool naturally; then the cooled mixed solution is suction filtered and washed 3 times to obtain bagasse pulp; then the bagasse pulp is put into a 250ml Erlenmeyer flask, and 20ml of mass concentration is added to bleach with hydrogen peroxide of 25%. to 75°C, magnetically stirred for 1 hour, cooled naturally, filtered and washed 3 times, put the bagasse obtained by suction into a conical flask, added 100ml of sodium hydroxide solution with a mass concentration of 6%, heated in an oil bath at 8...

Embodiment 3

[0050] (1) Wash a certain amount of wood with deionized water repeatedly for 3 times, put it in an oven at 90°C, and dry it for 11 hours; pulverize the dried wood with a grinder, and pass it through an 80-mesh sieve to obtain wood powder;

[0051] (2) Take 10g of 80-mesh wood flour and disperse it in 120ml of sodium hydroxide solution with a mass concentration of 8%, pour the mixture into a 250ml Teflon sealed tank, and put it in an oil bath at 110°C. After magnetic stirring for 1h, cool naturally; then the cooled mixed solution is suction filtered and washed 3 times; then the filter cake obtained by suction filtration is put into a 250ml Erlenmeyer flask, and 20ml of mass concentration is added to bleach with hydrogen peroxide of 30%. to 65°C, magnetically stirred for 1 hour, cooled naturally, filtered and washed 3 times, put the filter cake obtained by suction filtration into a conical flask, added 80ml of sodium hydroxide solution with a mass concentration of 4%, and heated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com