A kind of fermentation and separation and purification method of L-leucine

A technology for separation and purification and leucine, which is applied in the field of fermentation and separation and purification of L-leucine, can solve the problems of long operation cycle, large salt consumption, long time consumption, etc., and can reduce the generation of by-products and improve the sugar content. Acid conversion rate, simple and easy-to-control process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

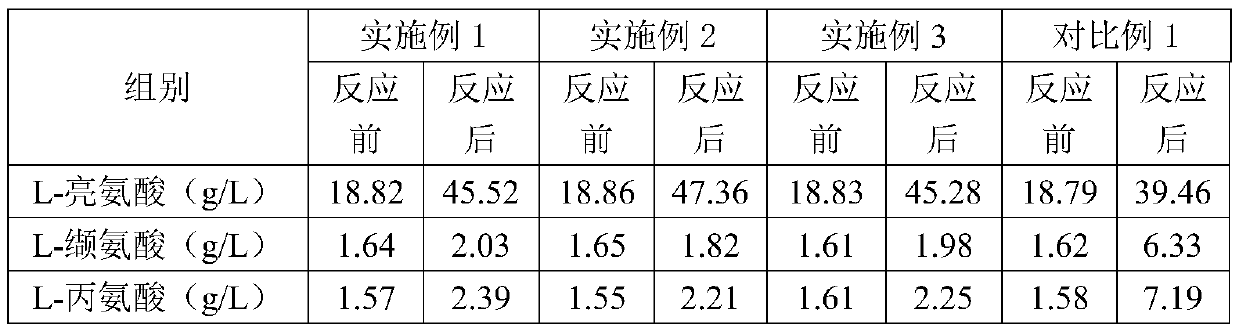

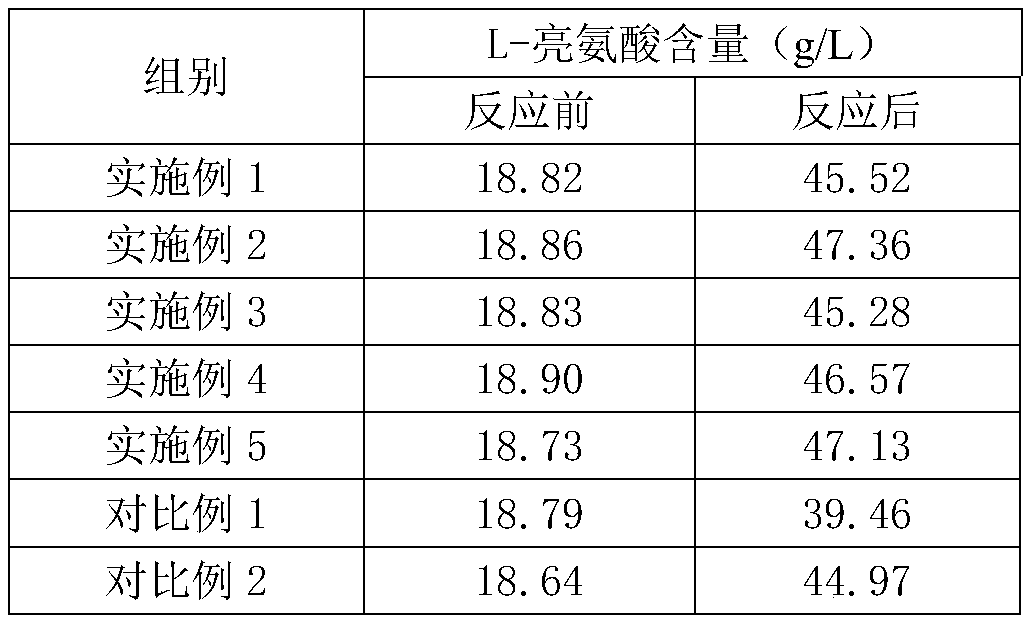

[0037] Embodiment 1: A kind of method of fermentation and separation and purification of L-leucine

[0038] The method for fermentation and separation and purification of L-leucine in the present invention comprises the following steps:

[0039] (1) Activation culture: Corynebacterium glutamicum and Brevibacterium ammoniagenes were respectively inoculated on the activation medium, activated and cultured in an incubator at 28°C for 12 hours to obtain activated bacteria;

[0040] The activation medium includes: anhydrous glucose 1g / L, peptone 10g / L, beef extract 10g / L, yeast extract 5g / L, NaCl 2.5g / L, agar powder 20g / L, pH=6.8-7.0.

[0041] (2) Seed culture: Take a ring of well-grown activated Corynebacterium corynebacterium ATCC21885 and Brevibacterium ammoniagenes BNCC183441, and inoculate them into shake flasks containing seed medium 1 and 2, respectively, with a liquid volume of 200mL / 500mL , the condition of seed culture is 28℃, 200r / min shaker culture for 20h, until the c...

Embodiment 2

[0050] Embodiment 2: A kind of method of fermentation and separation and purification of L-leucine

[0051] The only difference from Example 1 is that the ratio of the seed liquid of Corynebacterium glutamicum and Brevibacterium ammoniagenes inoculated in the fermentation culture in step (3) is 8:2.

Embodiment 3

[0052] Embodiment 3: A kind of method of fermentation and separation and purification of L-leucine

[0053] The only difference from Example 1 is that the ratio of the seed liquid of Corynebacterium glutamicum and Brevibacterium ammoniagenes inoculated in the fermentation culture in step (3) is 8:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular mass | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com