High-adhesion low-dielectric polyamide film and preparation method thereof

A technology of polyimide film and low dielectric, which is applied in the field of high adhesion and low dielectric polyimide film and its preparation, can solve the problems of polyimide film adhesion reduction, polyimide film mechanics Reduced performance, weakened adhesion of the upper layer material or the lower layer substrate, etc., to achieve the effect of reducing the dielectric constant, improving the bonding performance, and improving the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

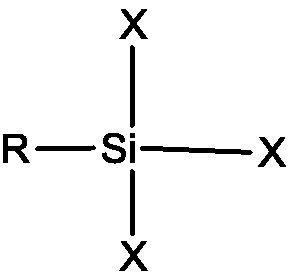

Method used

Image

Examples

Embodiment 1

[0030] Dissolve 1.09g of silica (particle size: 200-300nm) uniformly in 4.36g of DMAc (N,N-dimethylacetamide) to prepare 5.45g of silica sol (20wt%, DMAc) and add it to 1L In the reaction kettle, add 650g of DMAc and 1.359g of heptafluoropentyltriethoxysilane into the reaction kettle, start stirring, heat to 100°C, react for 2h, stop heating, drop to room temperature, add 76.97g (0.3844mol) 4, 4'-diaminodiphenyl ether (ODA), after dissolving and clarifying, add 83.85g (0.3844mol) pyromellitic dianhydride (PMDA), control the reaction temperature at 30°C, and react for 2h to obtain polyamic acid The solution has a solid content of 20% and a viscosity of 210000cps (30°C).

[0031] The prepared polyimide acid solution was coated on a glass (40*20cm) substrate, dried at 180°C for 20 minutes, then gradually heated to 380°C within 30 minutes, dried for 30 minutes, and cooled to obtain a 25 μm film.

Embodiment 2

[0033] Dissolve 1.6g of silica (particle size: 200-300nm) uniformly in 6.4g of DMAc (N,N-dimethylacetamide) to prepare 8g of silica sol (20wt%, DMAc) and add it to 1L of reaction In the kettle, add 632g DMAc and 2g heptafluoropentyltriethoxysilane into the reaction kettle, start stirring, heat to 100°C, react for 2h, stop heating, drop to room temperature, add 76.97g (0.3844mol) 4,4 '-Diaminodiphenyl ether (ODA), after dissolving and clarifying, add 83.85g (0.3844mol) pyromellitic dianhydride (PMDA), control the reaction temperature at 30°C, and react for 2h to prepare a polyamic acid solution , its solid content is 25.7%, viscosity 220000cps (30 ℃).

[0034] The prepared polyimide acid solution was coated on a glass (40*20cm) substrate, dried at 180°C for 20 minutes, then gradually heated to 380°C within 30 minutes, dried for 30 minutes, and cooled to obtain a 25 μm film.

Embodiment 3

[0036] Dissolve 1.714g of silica (particle size: 200-300nm) uniformly in 6.856g of DMAc (N,N-dimethylacetamide) to prepare 8.57g of silica sol (20wt%, DMAc) and add it to 1L In the reaction kettle, add 650g DMAc and 1.886g heptafluoropentyltriethoxysilane into the reaction kettle, start stirring, heat to 100°C, react for 2h, stop heating, lower to room temperature, add 76.97g (0.3844mol) 4 , 4'-diaminodiphenyl ether (ODA), after dissolving and clarifying, add 83.85g (0.3844mol) pyromellitic dianhydride (PMDA), control the reaction temperature at 30°C, and react for 2h to obtain polyamide Acid solution with a solid content of 20% and a viscosity of 220,000 cps (30°C).

[0037]The prepared polyimide acid solution was coated on a glass (40*20cm) substrate, dried at 180°C for 20 minutes, then gradually heated to 380°C within 30 minutes, dried for 30 minutes, and cooled to obtain a 25 μm film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com