Toughening and corrosion-resistant concrete additive

An additive and corrosion-resistant technology, which is applied in the field of toughened and corrosion-resistant concrete additives and its preparation, can solve the problems of compatible concrete structure damage and high engineering cost, improve stress distribution and failure form, reduce construction costs, reduce Effect of Crack Width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

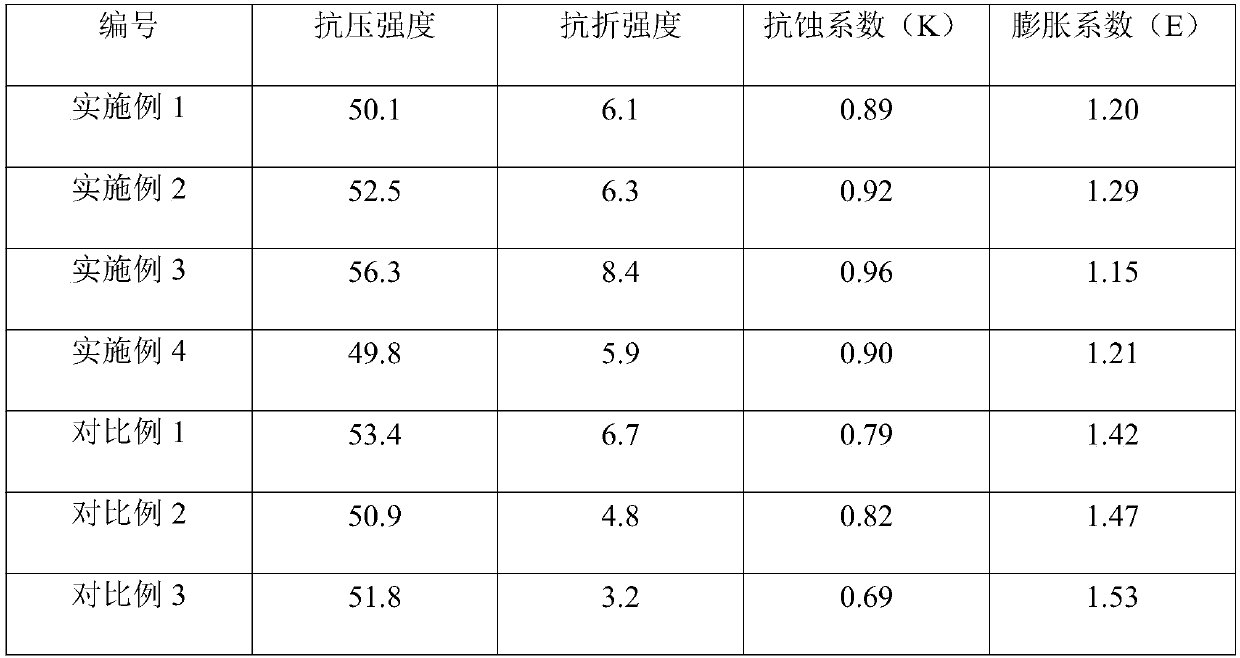

Embodiment 1

[0033] This embodiment provides a kind of toughened and corrosion-resistant concrete additive, including the following raw materials in mass percentage: mineral powder 35%, silicon micropowder 40%, polypropylene fiber 9%, modified furan resin 9%, silane coupling agent 0.1% , p-toluenesulfonic acid 0.2%, sodium sulfate 6.7%.

[0034] The modified furan resin is a phenolic modified furan resin.

[0035] The preparation method of a toughened and corrosion-resistant concrete additive described in this embodiment comprises the following steps: mixing mineral powder, modified furan resin, and silane coupling agent uniformly in proportion, and placing them in a grinder to grind to obtain a mixture , and then put the above-mentioned mixture, silicon micropowder, polypropylene fiber, p-toluenesulfonic acid, and sodium sulfate into a stirring container in proportion, and stir evenly at room temperature to obtain the additive.

[0036] This embodiment provides a method for using the tou...

Embodiment 2

[0044] This embodiment provides a toughening and corrosion-resistant concrete additive. Compared with Example 1, the difference is that the preparation method of the modified furan resin is: alkylated hydroxymethylphenol, furfuryl alcohol by mass ratio Mix 3:1, gradually raise the temperature to 140°C, add toluene to azeotropically remove water, and circulate distillation. After the water phase and toluene are removed by distillation, the temperature is lowered and cooled, and the material is discharged when the reaction reaches a suitable viscosity (4 cups for 25 seconds), and the modified furan resin is obtained.

[0045] Additives were prepared according to the method described in Example 1 to act on concrete to obtain concrete specimens for testing.

Embodiment 3

[0047] This embodiment provides a kind of toughened and corrosion-resistant concrete additive, compared with embodiment 1, the difference is that,

[0048] The preparation method of the modified furan resin is as follows: mix alkylated hydroxymethylphenol and furfuryl alcohol in a mass ratio of 3:1, gradually raise the temperature to 140° C., add toluene to azeotropically remove water, and circulate distillation. After the water phase and toluene are removed by distillation, the temperature is lowered and cooled, and the material is discharged when the reaction reaches a suitable viscosity (4 cups for 25 seconds), and the modified furan resin is obtained.

[0049] The preparation method of the alkylated hydroxymethyl phenol is as follows: heat and melt the phenol, then add an appropriate amount of concentrated sulfuric acid, heat the mixture to 100° C., then gradually add styrene, and the reaction is exothermic. When all the styrene has been added, the temperature should rise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com