In-situ nitrogen-doped hollow carbon ball and preparation method thereof and preparation method and application of electrode material

A technology of hollow carbon spheres and nitrogen doping, applied in battery electrodes, circuits, nanocarbons, etc., can solve the problems of wasting solvents and carbon sources, hindering industrial scale, and limiting practical applications, etc., and achieves small nanoscale and low price , Realize the effect of low-cost large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Weigh 0.05g of ammonia water, add 0.5g of ethanol and 5g of water into the mixture of water and sonicate for 10 minutes; then add 5g of formaldehyde solution and 0.033g of paracetamol (or o-acetaminophen, p-aminophenol and m-aminophenol, etc.);

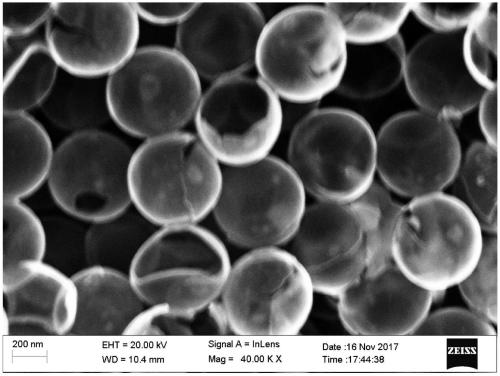

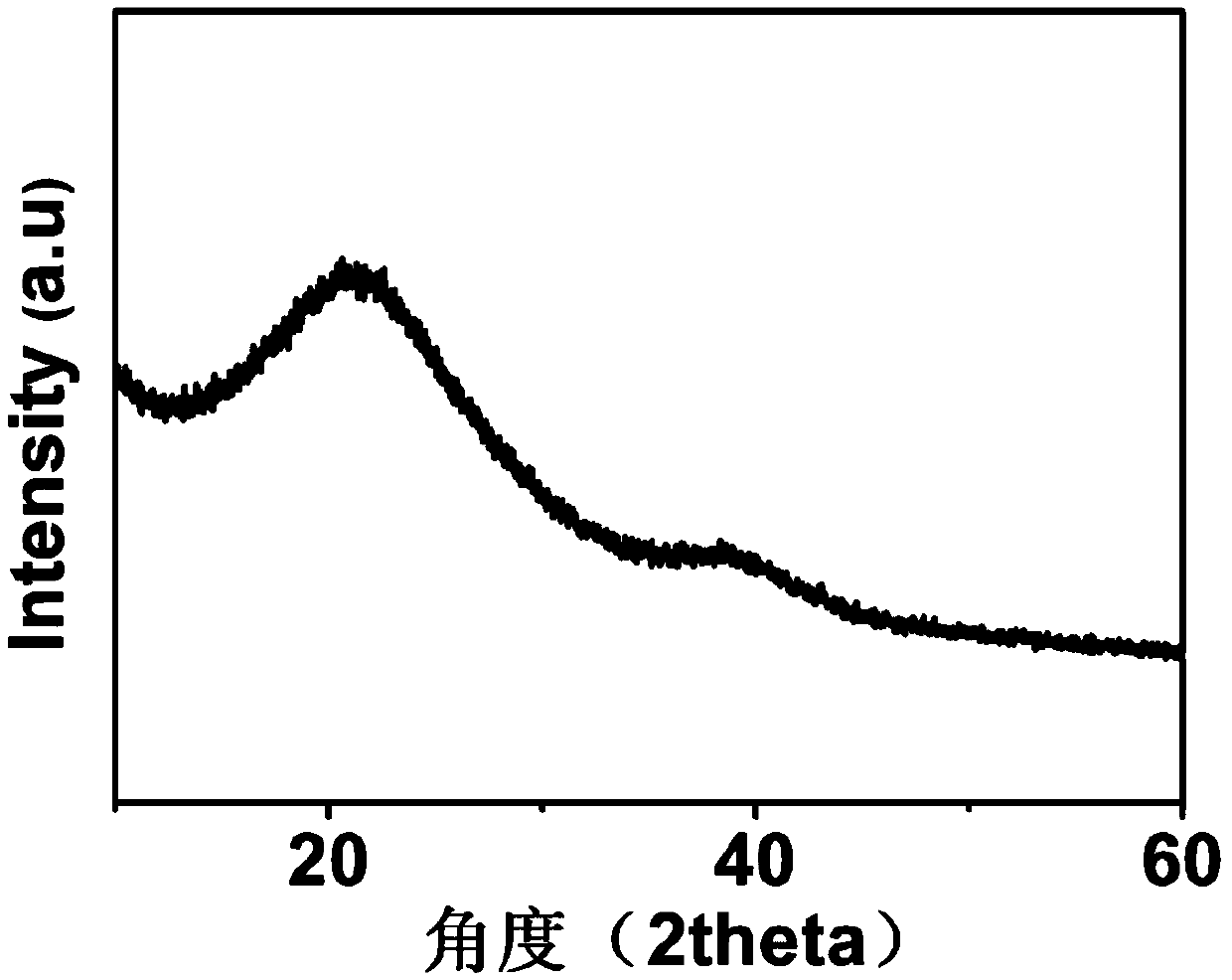

[0049] Then, 0.01 g of tetrapropyl orthosilicate (TPOS) or tetraethylsilicate (TEOS) was added to the above solution, and the solution was heated to 80° C. and kept for 100 h. Filter while hot, wash with water, and dry to obtain SiO coated with phenolic resin. 2 The microspheres were placed in a tube furnace and heated at 500 °C for 100 h under an argon atmosphere. Finally, soak the obtained sample in dilute sodium hydroxide solution for 1 hour, filter, wash with water, and dry to obtain in-situ nitrogen-doped hollow carbon spheres.

[0050] Grind the obtained in-situ nitrogen-doped hollow carbon spheres into powder, prepare materials according to the mass ratio of in-situ nitrogen-doped hollow carbon sphere powder: acetylene ...

Embodiment 2

[0053] Weigh 5g of ammonia water and add it to the mixture of 5g ethanol and 5g water and sonicate for 10 minutes; then add 8.2g formaldehyde solution and 4.5g p-aminophenol respectively. Then, 88 g of tetraethyl silicate (TEOS) was added to the above solution, and the solution was heated to 80° C. and kept for 6 h. Filter while hot, wash with water, and dry to obtain SiO coated with phenolic resin. 2 The microspheres were placed in a tube furnace and heated at 1100 °C for 3 h under an argon atmosphere. Finally, soak the obtained sample in dilute sodium hydroxide solution for 48 hours, filter, wash with water, and dry to obtain in-situ nitrogen-doped hollow carbon spheres.

[0054] Grind the obtained in-situ nitrogen-doped hollow carbon spheres into powder, prepare materials according to the mass ratio of in-situ nitrogen-doped hollow carbon sphere powder: acetylene black: PVDF is 80:10:10, place them in a mortar and add NMP, Grind to a uniform paste; and control the thickne...

Embodiment 3

[0057] Weigh 32g of ammonia water and add 1.6g of ethanol and 0.32g of water into a mixture of 1.6g of ethanol and 0.32g of water to sonicate for 10 minutes; then add 5g of formaldehyde solution and 19g of o-acetaminophen respectively. Then 12 g of tetrapropyl orthosilicate (TPOS) was added to the above solution, and the solution was heated to 80° C. and kept for 17 hours. Filter while hot, wash with water, and dry to obtain SiO coated with phenolic resin. 2 The microspheres were placed in a tube furnace and heated at 900 °C for 6 h under an argon atmosphere. Finally, soak the obtained sample in dilute sodium hydroxide solution for 24 hours, filter, wash with water, and dry to obtain in-situ nitrogen-doped hollow carbon spheres.

[0058] Grind the obtained in-situ nitrogen-doped hollow carbon spheres into powder, prepare materials according to the mass ratio of in-situ nitrogen-doped hollow carbon sphere powder: acetylene black: PVDF is 80:10:10, place them in a mortar and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com