Stirring head for hybrid connection of aluminum-copper dissimilar metal objects, and welding technology

A technology of dissimilar metals and welding processes, which is applied in metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as difficult to break dispersed welded joints and welding defects, and achieve the reduction of intermetallic compounds Effects of generation, improved welding stability, and expanded welding parameter range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Step 1: Use alcohol to clean the surface of the dissimilar metal plate and the oil stains and oxides on the interface that hinder the welding process, place the cleaned plate on the workbench, and fix the plate on the workbench by pressing the plate and other tooling superior.

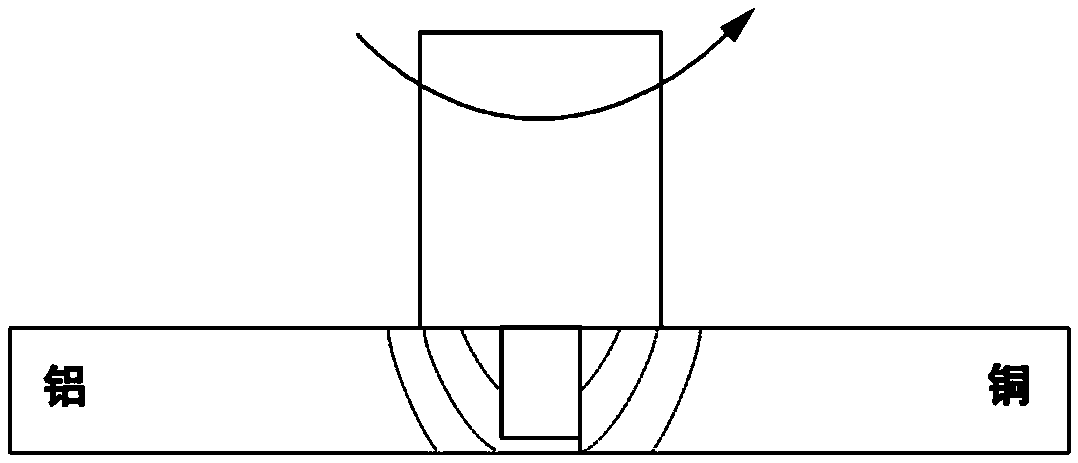

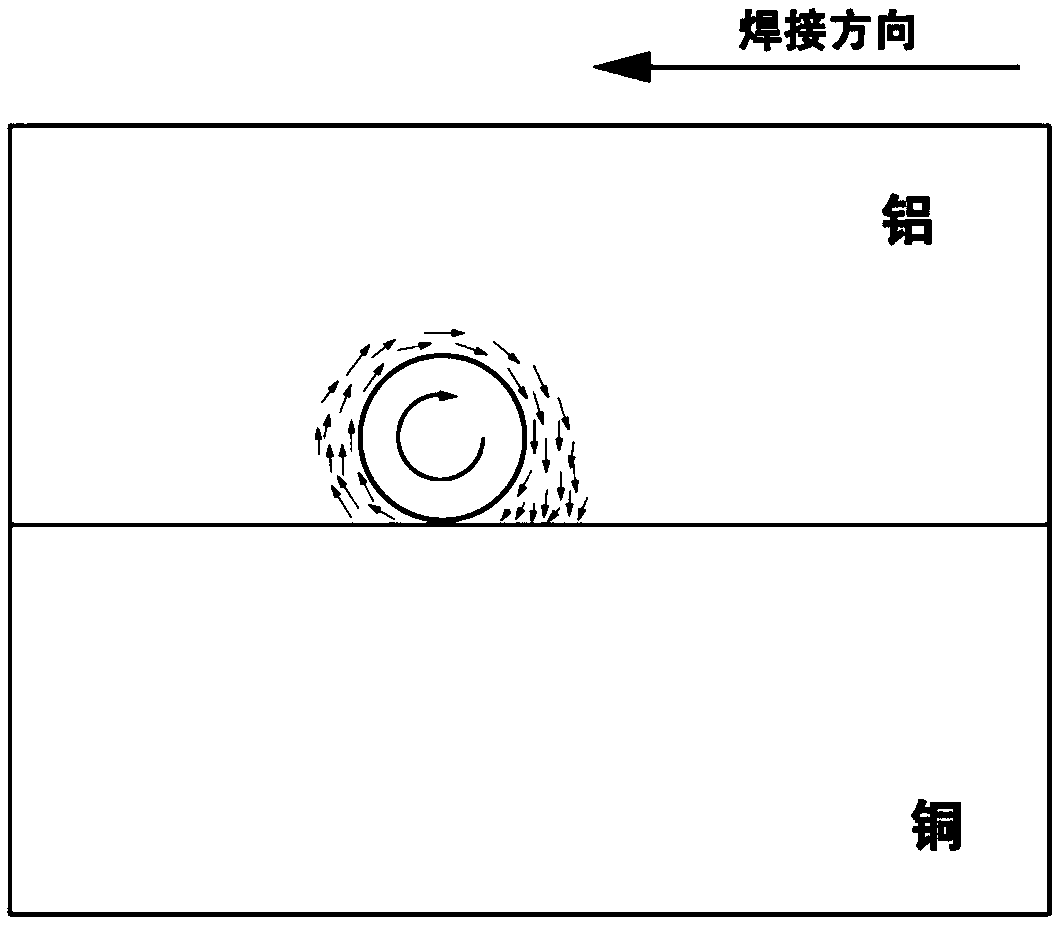

[0052] Step 2: Start the friction stir welding equipment, adjust the position of the stirring head, first place the center point of the stirring end face directly above the center of the weld, and then move the stirring needle so that the stirring needle is completely placed on the aluminum side, and the contour line of the edge of the stirring needle is in line with the welding seam The center line is tangent, and finally adjust the distance between the contour line of the edge of the stirring needle and the center of the weld seam to determine the welding position.

[0053] Step 3: Set the welding parameters. The rotation speed of the stirring head is set between 400rpm, the welding speed is s...

Embodiment 2

[0058] Step 1: Use alcohol to clean the surface of the dissimilar metal plate and the oil stains and oxides on the interface that hinder the welding process, place the cleaned plate on the workbench, and fix the plate on the workbench by pressing the plate and other tooling superior.

[0059] Step 2: Start the friction stir welding equipment, adjust the position of the stirring head, first place the center point of the stirring end face directly above the center of the weld, and then move the stirring needle so that the stirring needle is completely placed on the aluminum side, and the contour line of the edge of the stirring needle is in line with the welding seam The center line is tangent, and finally adjust the distance between the contour line of the edge of the stirring needle and the center of the weld seam to determine the welding position.

[0060] Step 3: Set the welding parameters. The rotation speed of the stirring head is set between 600rpm, the welding speed is s...

Embodiment 3

[0065] Step 1: Use alcohol to clean the surface of the dissimilar metal plate and the oil stains and oxides on the interface that hinder the welding process, place the cleaned plate on the workbench, and fix the plate on the workbench by pressing the plate and other tooling superior.

[0066] Step 2: Start the friction stir welding equipment, adjust the position of the stirring head, first place the center point of the stirring end face directly above the center of the weld, and then move the stirring needle so that the stirring needle is completely placed on the aluminum side, and the contour line of the edge of the stirring needle is in line with the welding seam The center line is tangent, and finally adjust the distance between the contour line of the edge of the stirring needle and the center of the weld seam to determine the welding position.

[0067] Step 3: Set the welding parameters. The rotation speed of the stirring head is set between 650rpm, the welding speed is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com