A kind of potassium feldspar selection method

A potassium feldspar and flotation technology, which is applied in the field of potassium feldspar selection, can solve the problems of acid leaching and flotation effluents with high toxicity, environmental pollution, and failure to remove mica.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, a method for beneficiating potassium feldspar includes raw ore cleaning, screening, crushing, ore grinding, flotation and dehydration, and the flotation includes primary flotation and secondary flotation;

[0022] The primary flotation is as follows: add water to the 200-mesh fine sand particles obtained by grinding to adjust the concentration of 25% pulp, adjust the pH of the pulp to 3, add the extract of 8% of the mass of the pulp, and stir for 2 minutes , then add the coconut extract with 4% of the mass of the pulp, stir until foaming, scrape off the foam, rinse with clear water, dehydrate to a water content of 25%, and obtain deironized ore; The content is 109mg / 100g, and the volume concentration of coconut oil in the coconut extract is 90%.

[0023] The secondary flotation is as follows: adding water to the de-ironized ore to adjust the concentration of 35% pulp, and adjusting the pH of the pulp to 1, adding medicaments with a mass of 3% of the ...

Embodiment 2

[0030] In this embodiment, a method for beneficiating potassium feldspar includes raw ore cleaning, screening, crushing, ore grinding, flotation and dehydration, and the flotation includes primary flotation and secondary flotation;

[0031] The primary flotation is as follows: add water to the 250-mesh fine sand particles obtained by grinding to adjust the concentration of 35% pulp, adjust the pH of the pulp to 5, add the extract of 11% of the mass of the pulp, and stir for 4 minutes , then add the coconut extract with 9% of the mass of the pulp, stir until foaming, scrape off the foam, rinse with clear water, dehydrate to a water content of 20%, and obtain de-iron ore; The content of cyanine polysaccharide is 120mg / 100g, and the volume concentration of coconut oil in the coconut extract is 95%.

[0032] The secondary flotation is as follows: adding water to the de-ironized ore to adjust the concentration of 45% pulp, and adjusting the pH of the pulp to 2, adding medicaments w...

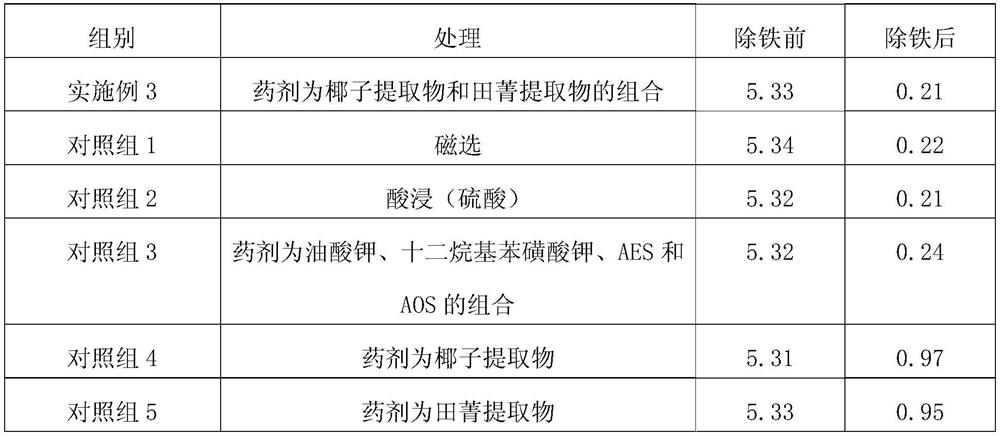

Embodiment 3

[0039] In this embodiment, a method for beneficiating potassium feldspar includes raw ore cleaning, screening, crushing, ore grinding, flotation and dehydration, and the flotation includes primary flotation and secondary flotation;

[0040] The primary flotation is: add water to the 300-mesh fine sand particles obtained by grinding to adjust the concentration of 30% pulp, adjust the pH of the pulp to 4, add the extract of 9% of the mass of the pulp, and stir for 3 minutes , then add the coconut extract with 6% of the mass of the pulp, stir until foaming, scrape off the foam, rinse with clear water, and dehydrate to a water content of 18% to obtain de-iron ore; The polysaccharide content is 105mg / 100g, and the coconut oil volume concentration in the coconut extract is 92%.

[0041] The secondary flotation is as follows: add water to the de-ironized ore to adjust the concentration of 40% pulp, and adjust the pH of the pulp to 1.5, then add a medicament with a mass of 4% of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com