A pt-tio 2 -sio 2 Photocatalytic self-cleaning composite material and preparation method thereof

A pt-tio2-sio2, composite material technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of narrow photoresponsivity range and complex operation , inapplicability and other problems, to achieve the effects of strong hydrophobicity and self-cleaning ability, wide light response range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a Pt-TiO 2 -SiO 2 Photocatalytic self-cleaning composite material and preparation method thereof.

[0033] At room temperature, add 0.414g oxalic acid, 7.2g deionized water, 4g absolute ethanol and 2.2g PDMS to a 100mL single-necked flask, and magnetically stir for 90min to obtain a two-phase solution; take 16g absolute ethanol, 0.48g TTIP and 1.37mg of chloroplatinic acid solution (concentration: 10g / L) was magnetically stirred and mixed in a 50mL beaker to obtain solution A; -1 Slowly add solution A dropwise to the biphasic solution within 2 hours at a rate of 2 hours, stir and react for 24 hours. -2 ) under light for 20 minutes; after the reaction, add 20.83g TEOS, continue to stir and react for 2 hours, and obtain a transparent and uniform sol, which is the Pt-TiO 2 -SiO 2 Photocatalytic self-cleaning composite material, label PTS-1 (P: Pt; T: TiO 2 ; S: SiO 2 ).

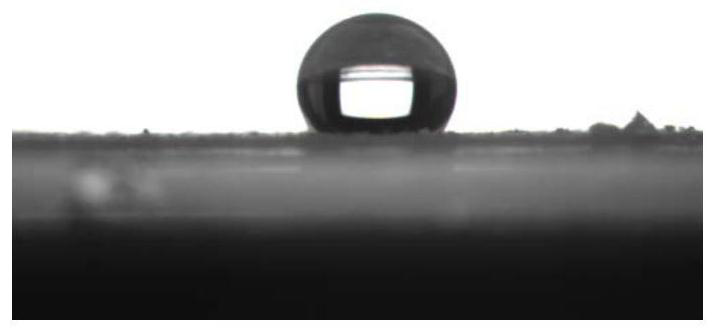

[0034] The physical figure of the product obtained in this embodiment ...

Embodiment 2

[0038] At room temperature, add 0.43g oxalic acid, 7.2g deionized water, 4g absolute ethanol and 2.2g PDMS to a 100mL single-necked flask, and magnetically stir for 110min to obtain a two-phase solution; take 16g absolute ethanol, 0.49g TTIP and 8.8mg of chloroplatinic acid solution was magnetically stirred and mixed in a 50mL beaker to obtain solution A, and then used a flow-type peristaltic pump at 150μL·min -1 Slowly add solution A dropwise to the biphasic solution within 140min at a rate of 140min, stir and react for 22h. -2) under light for 25min; after the reaction, add 21.0g TEOS, continue to stir and react for 1.5h, and obtain a transparent and uniform sol, which is the Pt-TiO 2 -SiO 2 Photocatalytic self-cleaning composite material, marked PTS-2.

[0039] The product obtained in this embodiment is used for visible light catalytic degradation of methyl orange, and the results are as follows Figure 4 As shown, after 52h of visible light (8W×4, 15cm), methyl orange (...

Embodiment 3

[0041] At room temperature, add 0.5g oxalic acid, 8.0g deionized water, 4g absolute ethanol and 2.5g PDMS to a 100mL single-necked flask, and magnetically stir for 120min to obtain a two-phase solution; take 16g absolute ethanol, 0.5g TTIP and 88mg of chloroplatinic acid solution was magnetically stirred and mixed in a 50mL beaker to obtain solution A, and then used a flow type peristaltic pump at 200μL·min -1 Slowly add solution A dropwise to the two-phase solution within 130min at a rate of 130min, stir and react for 23h, during -2 ) under light for 15 minutes; after the reaction, add 25g TEOS, continue to stir and react for 2 hours, and obtain a transparent and uniform sol, which is the Pt-TiO 2 -SiO 2 Photocatalytic self-cleaning composite material, marked PTS-3.

[0042] The product obtained in this embodiment is used for visible light catalytic degradation of methyl orange, and the results are as follows Figure 5 As shown, after 52h of visible light (8W×4, 15cm), met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com