A kind of soft magnetic composite material and preparation method thereof

A soft magnetic composite material, lye technology, applied in the direction of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the saturation magnetic induction intensity and permeability decrease, the insulation layer saturation magnetic induction intensity is not high, can not be carried out. High heat treatment and other problems to achieve the effect of reducing loss and forming, conducive to uniform coating and small magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

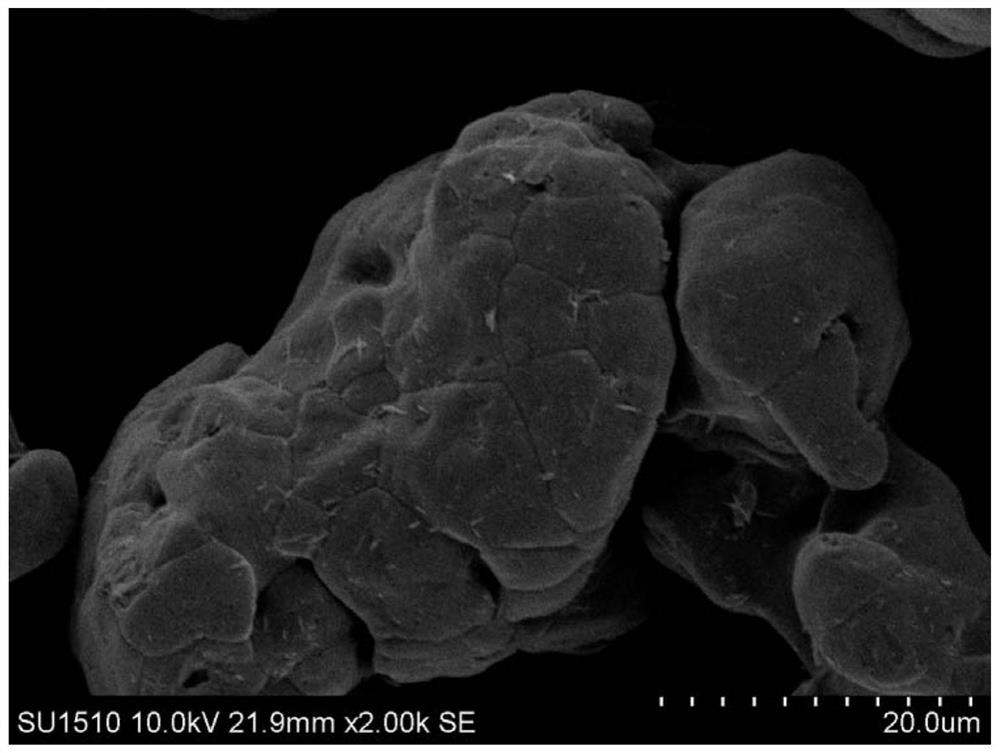

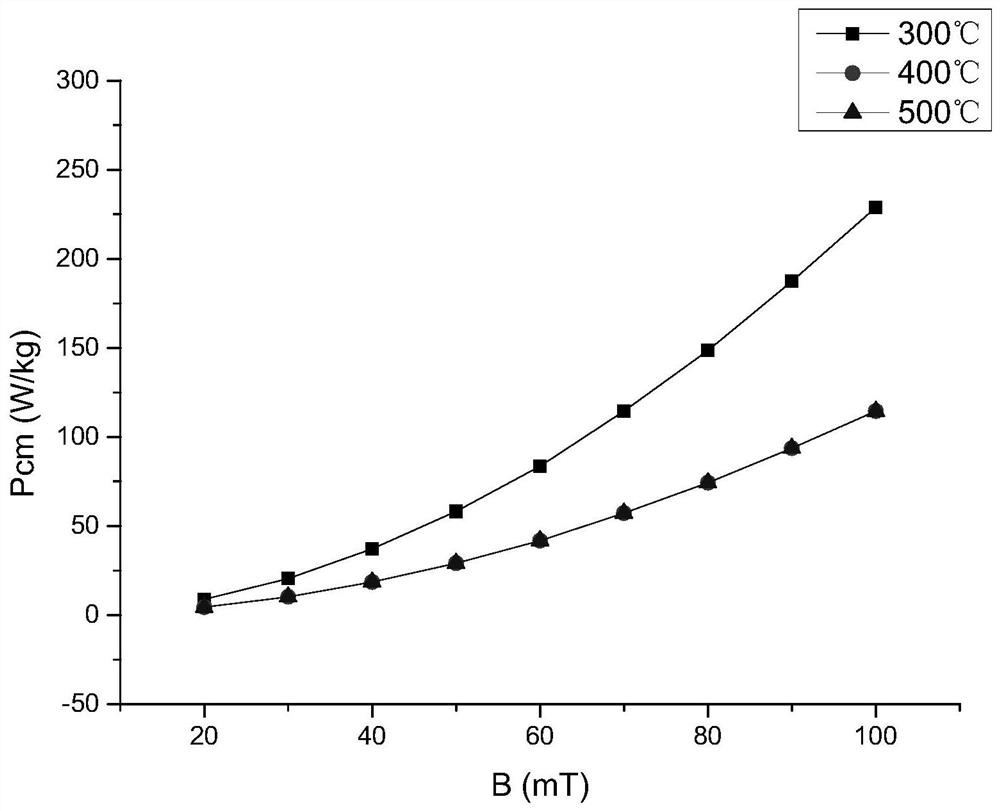

[0025] Weigh 60gNaOH and 20gNaNO 2 Dissolve in 90ml of distilled water, pour the mixture of the two into a three-necked flask and heat to 140°C, add 20g of pure iron powder and 0.1g of carbon black and stir for 30min, filter, wash the filter cake with hot water until the pH is neutral, and then use absolute ethanol Wash 3 times; put the sample in a vacuum drying oven for 30 minutes at 65°C to obtain 20g of pretreated pure iron powder; grind and mix 20g of pretreated pure iron powder with 0.01g of nickel stearate and 0.01g of oleic acid amide Uniform, then pressed into a ring (12.7mm OD x 7.6mm ID x 3mm tall) at 25°C and 1200MPa; slowly (2°C / min) in a mixed atmosphere of water vapor-nitrogen (water vapor volume content 10%) The temperature is raised to 350° C. for 30 minutes, and then the temperature is raised to 500° C. for 60 minutes to obtain a soft magnetic composite material. Subsequent performance tests were performed on the pressure-wrapped wire. The primary coil and th...

Embodiment 2

[0027] Weigh 60gNaOH and 20gNaNO 2 Dissolve in 90ml of distilled water, pour the mixture of the two into a three-necked flask and heat to 140°C, add 20g of pure iron powder and 0.1g of carbon nanotubes and stir for 30min, filter, wash the filter cake with hot water until the pH is neutral, and then anhydrous Wash with ethanol 3 times; put the sample in a vacuum drying oven and dry at 65°C for 30 minutes to obtain 20 g of pretreated pure iron powder; grind 20 g of pretreated pure iron powder with 0.01 g of zinc stearate and 0.01 g of stearic acid Mix evenly, and then press it into a ring (12.7mm OD×7.6mm ID×3mm tall) at 25°C and 1200MPa; press the ring in a water vapor-nitrogen (water vapor volume content of 15%) mixed atmosphere at 2°C / min The temperature was raised to 200°C for 30 minutes, and then heated to 400°C for 60 minutes to obtain a soft magnetic composite material. Subsequent performance tests were performed on the pressure-wrapped wire. The primary coil and the sec...

Embodiment 3

[0029] Weigh 60gNaOH and 20gNaNO 2Dissolve in 90ml of distilled water, pour the mixture of the two into a three-neck flask and heat to 140°C, add 20g of pure iron powder and 0.1g of graphene and stir for 30min, filter, wash the filter cake with hot water until the pH is neutral, and then use absolute ethanol Wash 3 times; put the sample in a vacuum drying oven for 30 minutes at 65°C to obtain 20g of pretreated pure iron powder; mix 20g of pretreated pure iron powder with 0.01g of zinc stearate, 0.01g of N,N'- Grind and mix ethylene bisstearamide evenly, and then press it into a ring (12.7mm OD×7.6mm ID×3mm tall) at 25°C and 1200MPa; place the pressed ring in a mixed atmosphere of water vapor-nitrogen (water vapor volume content 5%) The temperature was raised at 3°C / min to 300°C for 30 minutes, and then heat treated at 300°C for 60 minutes to obtain a soft magnetic composite material. Subsequent performance tests were performed on the pressure-wrapped wire. The primary coil an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com