Preparation method and application of collagen-based adhesive

A technology of collagen and base glue, which is applied in the field of preparation of collagen-based adhesives, can solve the problems of unfavorable production environment and consumers, difficult control of the reaction process, etc., achieve good application prospects, overcome poor water resistance, and have good water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

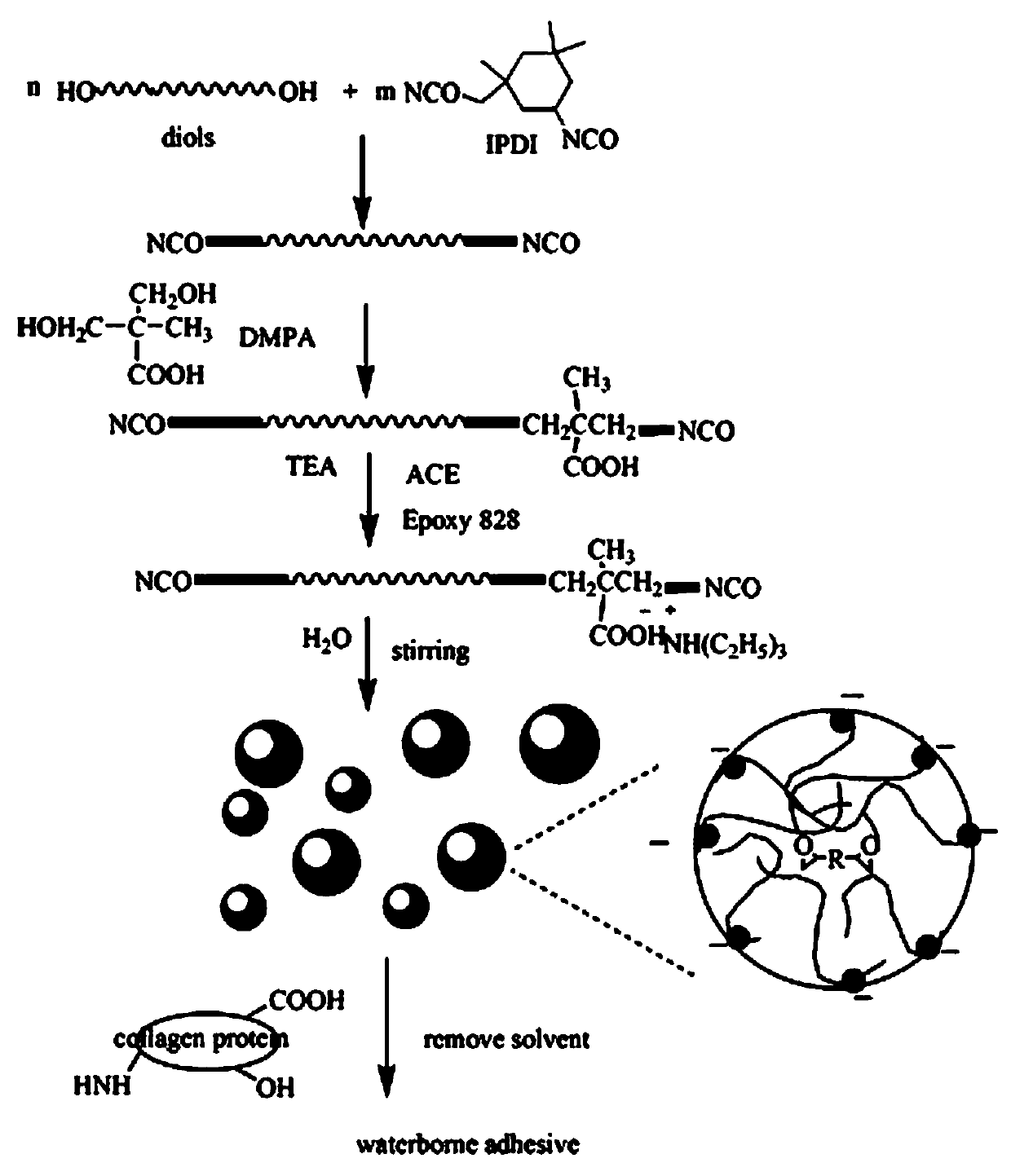

Method used

Image

Examples

preparation example 1

[0046] Step 1: Synthesize PU prepolymer containing hydrophilic group and terminal isocyanate. details as follows:

[0047] Add 56g of polyethylene adipate diol (PEA) and 19.23g of isophorone diisocyanate (IPDI) with a molecular weight of 2000 into a three-necked flask, 0.16g of an organotin catalyst, react at 50°C for 30min and then heat up to 80°C ℃ and keep it warm for 1h; then lower the temperature to 70℃, add 4.34g dimethylolpropionic acid (DMPA) and 11.9g butanone (MEK), react for 30min, then raise the temperature to 80℃, and continue the reaction for 2~3h until -NCO The content is close to the theoretical value (detected by the di-n-butylamine method), the temperature is lowered to 35°C, and 20 parts by mass of acetone (ACE) is added to reduce the viscosity to 1000mPas to obtain a PU prepolymer. Add epoxy 828, 2.37g to the PU prepolymer Triethylamine (TEA) forms a salt with the carboxyl group in the PU prepolymer.

[0048] Step 2: Polyurethane, epoxy resin graft collag...

preparation example 2

[0055] Step 1: Synthesize PU prepolymer containing hydrophilic group and terminal isocyanate. details as follows:

[0056] Get 40.00 g of hexanediol adipate diol (PHA) with a molecular weight of 2000 in a three-necked flask, heat it in an oil bath at 50° C., add 10.44 g TDI, 0.16 g organic bismuth catalyst to react in the flask successively for 30 min; heat up to 65°C, react for 20min, then raise the temperature to 80°C, and react for 60min; lower the temperature to 70°C, add 2.657g DMPA and 2.6705g butanone into the flask, react for 30min, raise the temperature to 80°C, react for 2h, synthesize - NCO terminated PU prepolymer. Lower the flask to room temperature, add 10.7g of acetone to reduce the viscosity to 1200mPas, add 19.767g of epoxy 828, 2.002g of TEA, stir for 1min, and form a salt.

[0057] In this step, 0.0534gH can also be added 3 PO 4 , together with the catalyst.

[0058] Step 2: PU, epoxy resin graft collagen hydrolyzate. details as follows:

[0059] Add ...

preparation example 3

[0062] Step 1: Synthesize PU prepolymer containing hydrophilic group and terminal isocyanate. details as follows:

[0063] Get 40.00 g of butanediol adipate diol (PBA) of molecular weight 2000 in a three-necked flask, heat in an oil bath at 50° C., add 10.44 g TDI, 0.1 g organic bismuth catalyst to react in the flask successively for 30 min; heat up to 65°C, react for 20min, then raise the temperature to 80°C, and react for 60min; lower the temperature to 70°C, add 2.657g DMPA and 2.6705g butanone into the flask, react for 30min, raise the temperature to 80°C, react for 2h, synthesize - NCO terminated PU prepolymer. Add acetone to reduce the viscosity to 1200mPas, add 19.767g epoxy 828, 2.002gTEA, stir for 1min, and form a salt.

[0064] In this step, 0.05gH can also be added 3 PO 4 , together with the catalyst.

[0065] Step 2: PU, epoxy resin graft collagen hydrolyzate. details as follows:

[0066] Lower the flask to room temperature, add 10.682g of acetone, add 58g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com