Packaging film for electrochemical battery and manufacturing method thereof

An electrochemical and packaging film technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low peel strength and deep drawing performance, inconvenient identification and storage management, affecting the normal use of batteries, etc. Identification and storage management, to achieve the effect of appearance differentiation, peel strength and deep drawing performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

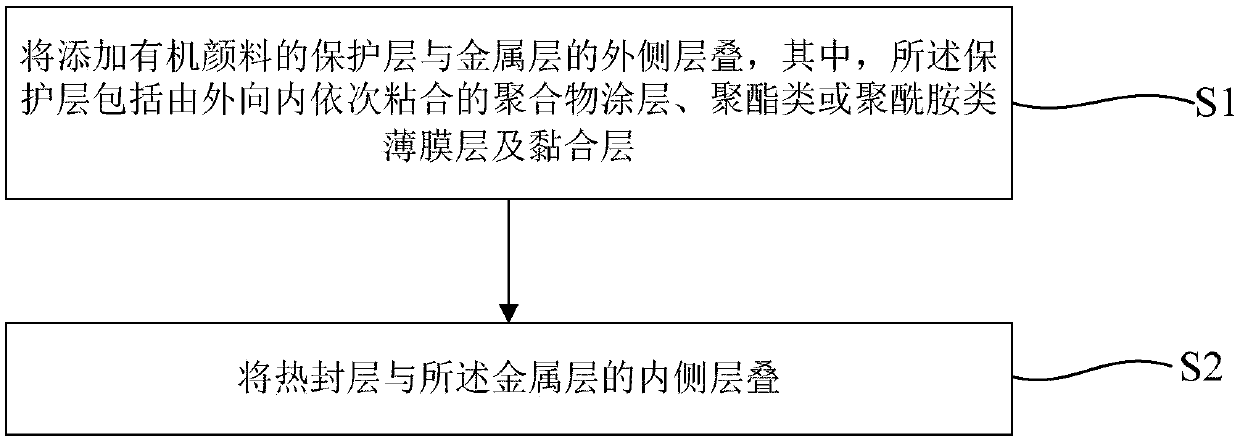

[0059] Such as figure 1 and image 3 Shown, the present invention also provides a kind of preparation method of packaging film for electrochemical cell, utilize described preparation method to prepare above-mentioned packaging film for electrochemical cell, the performance of the packaging film for electrochemical cell that described preparation method makes, For the parameters, refer to the aforementioned examples, which will not be repeated here, and only the preparation method will be described. Described preparation side comprises:

[0060] S1, laminating the protective layer 3 added with organic pigments on the outer side of the metal layer 1, wherein the protective layer 3 includes polymer coatings 31, 32 and an adhesive layer 33 bonded sequentially from outside to inside;

[0061] S2, laminating the heat-sealing layer 2 on the inner side of the metal layer 1 .

[0062] As an example, the lamination method in step S1 includes a dry coating method; the lamination metho...

Embodiment 1

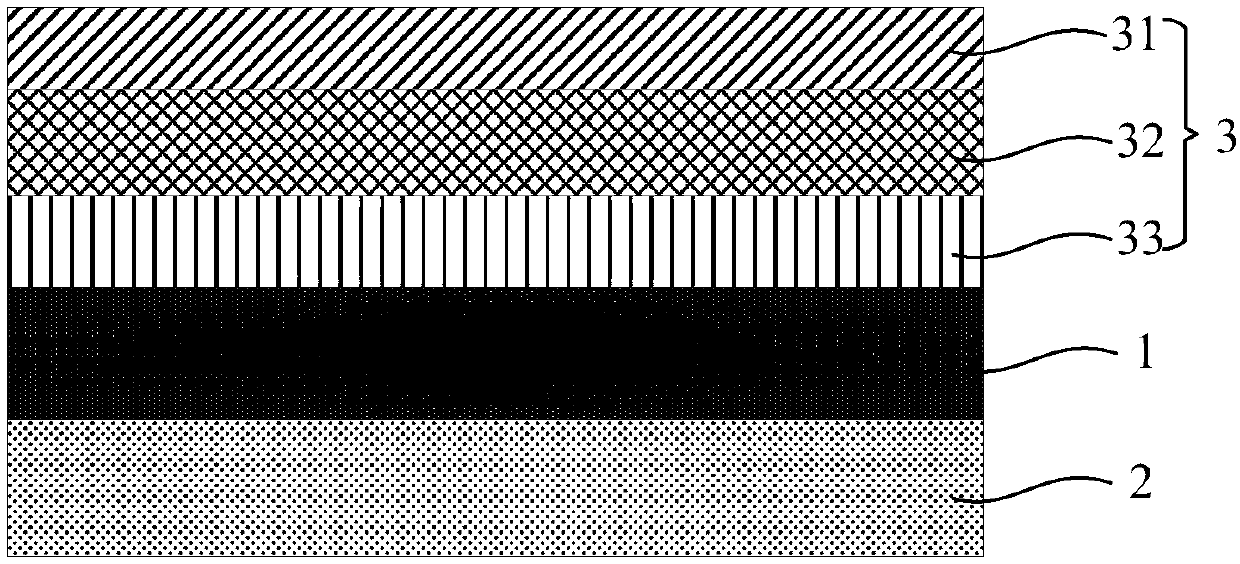

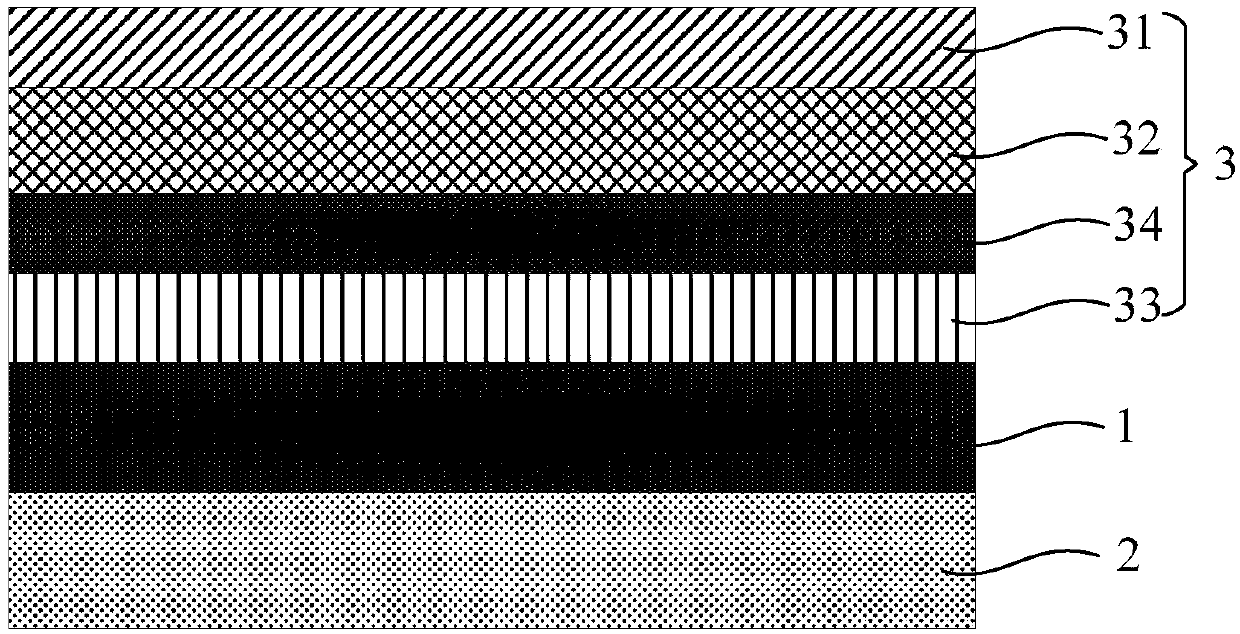

[0069] Such as figure 1 As shown, the packaging film for electrochemical cells described in this embodiment includes from the outside to the inside: a polymer coating 31 added with organic pigments, a transparent high-temperature-resistant polyester or polyamide film layer 32, a transparent A high temperature resistant adhesive layer 33 , a metal layer 1 and a transparent hot-melt polypropylene film layer 2 . Among them, the polymer coating 31 is a color layer, the high temperature resistant polyester or polyamide film layer 32, the high temperature resistant adhesive layer 33 and the hot melt polypropylene film layer 2 are all transparent layers.

[0070] Described high-temperature-resistant type polyester or polyamide film layer 32 is for example selected the 25um thick biaxially oriented polyamide film (BOPA) of Japan Xingren Company, and described metal layer 1 selects the 40um of Japanese Toyo Aluminum Co., Ltd. Thick O state soft aluminum foil, described hot-melt type p...

Embodiment 2

[0074] Such as figure 1 As shown, the electrochemical cell packaging film described in this embodiment includes from the outside to the inside: a polymer coating 31, a high-temperature resistant polyester or polyamide film layer 32 added with organic pigments, a transparent high-temperature resistant Adhesive layer 33 , metal layer 1 and transparent hot-melt polypropylene film layer 2 . Among them, the high-temperature-resistant polyester or polyamide film layer 32 added with organic pigments is the color layer, and the polymer coating 31, the high-temperature-resistant adhesive layer 33 and the hot-melt polypropylene film layer 2 are all transparent layers. .

[0075] Described high-temperature-resistant type polyester or polyamide film layer 32 is for example selected the 25um thick biaxially oriented polyamide film (BOPA) of Japan Xingren Company, and described metal layer 1 selects the 40um of Japanese Toyo Aluminum Co., Ltd. Thick O state soft aluminum foil, described h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com