High-power chip flexible interconnection module and processing method

A technology of flexible interconnection and processing methods, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as insufficient reliability, achieve the effect of increasing the contact area, reducing the occurrence of hot spots, and improving the current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific technical scheme adopted is as follows:

[0054] (1) Flexible interconnection module design

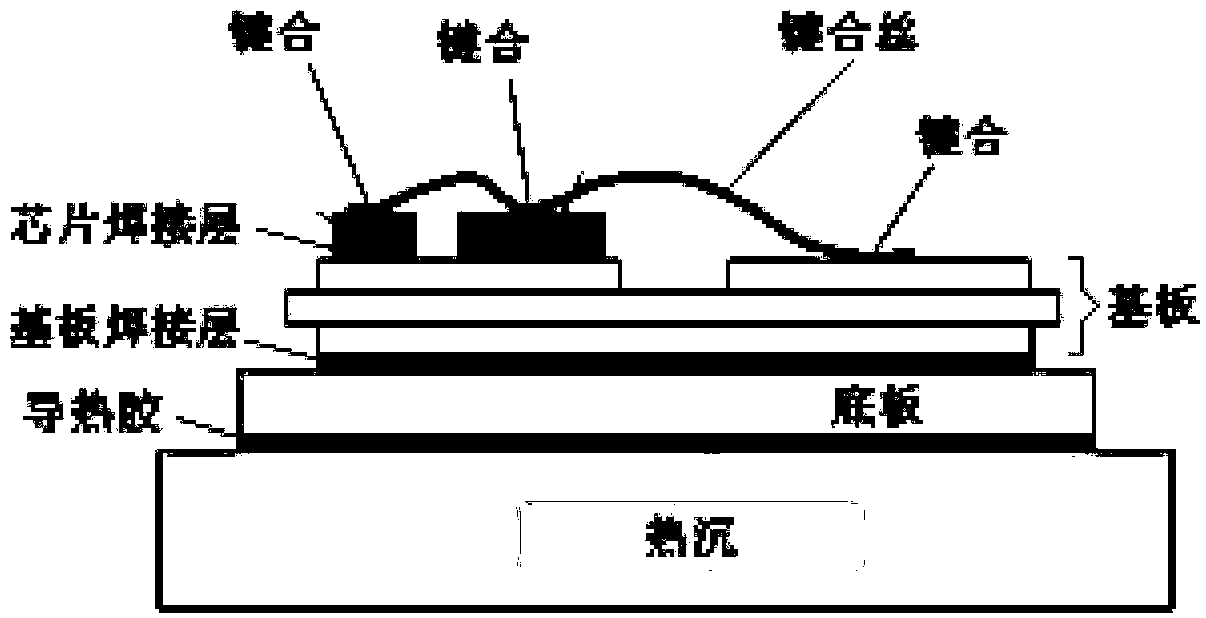

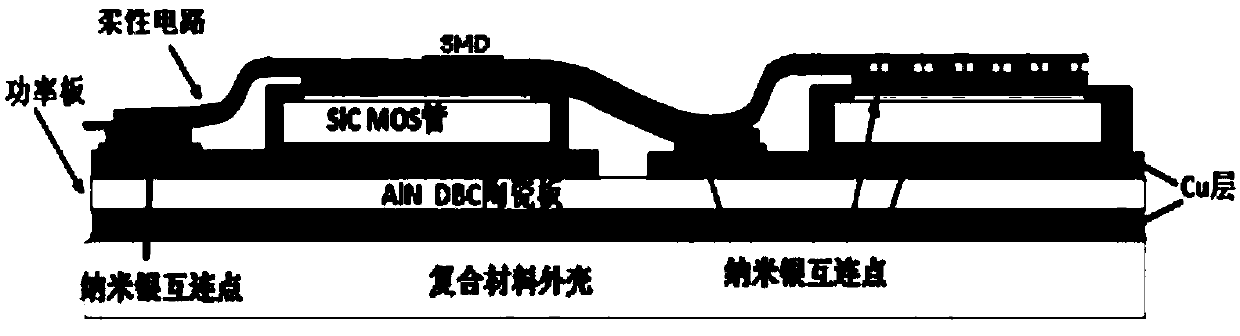

[0055] combine figure 2 , the flexible interconnection module includes a bare core, a ceramic board and a composite material shell, the bare cores are interconnected through a flexible interconnection structure, the bare core is welded to the ceramic plate, and the ceramic plate is welded to the composite material shell. For the flexible interconnect structure, polyimide film is selected as the flexible dielectric film, which is welded to the surface of the chip through nano-silver.

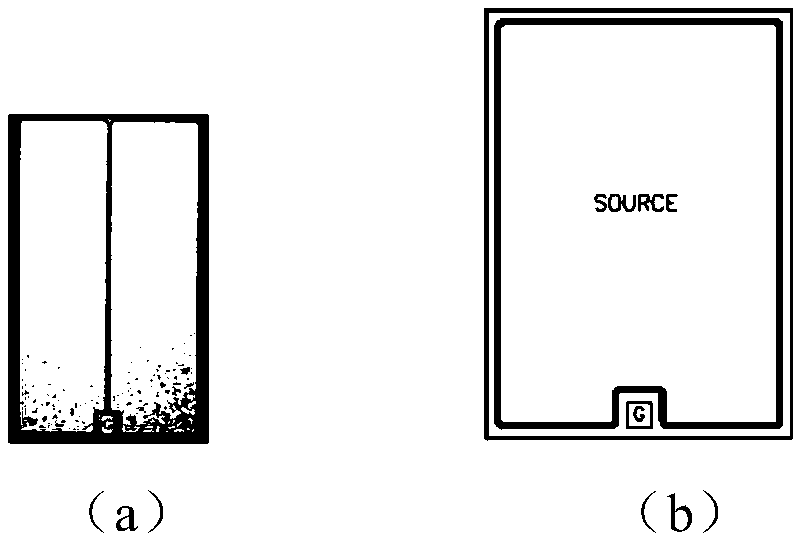

[0056] According to the distribution of chip electrodes and the layout of chips on the substrate, the flexible interconnection structure is designed. The layout of VDMOS chips IRFC260N (V1) and IRFC2907 (V2) is as follows: image 3As shown, the chip size is 4.597mm×7.696mm, 6.53mm×9.14mm, and the gate size is 0.51

[0057] mm × 0.51mm, 0.558mm × 0.558mm, the back of the chip is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com